- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

45

-

Core Components:

-

Control System, Servo System, Touch screen control

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.12 - 2 mm

-

Heating Power (kW):

-

116 kW

-

Air Comsumption(L/min):

-

0 L/min

-

Water Comsumption(L/min):

-

0 L/min

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Hao Feng

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

12000*2600*2600mm

-

Weight (T):

-

17 T

-

Power(KW):

-

155

-

Keyword:

-

Fast Food Packaging Box machine

-

Customization:

-

we can change it to automation package

-

Marketing Type:

-

Hot Product 2022

-

Finished product:

-

biodegradable food container machine

-

Forming Area:

-

780*650mm

-

Forming depth:

-

150mm

-

Max sheet roller diameter:

-

800

-

Function:

-

Forming - Cutting - Punching-Stacking

-

Heating Oven:

-

3 sections heating

-

Certification:

-

Video technical support, Free spare parts, Field installat

Quick Details

-

Max.Forming Height(mm):

-

150 mm

-

Forming Width (mm):

-

650 mm

-

Forming Length (mm):

-

780 mm

-

Production Speed(Cycles/min):

-

45

-

Core Components:

-

Control System, Servo System, Touch screen control

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.12 - 2 mm

-

Heating Power (kW):

-

116 kW

-

Air Comsumption(L/min):

-

0 L/min

-

Water Comsumption(L/min):

-

0 L/min

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Hao Feng

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

12000*2600*2600mm

-

Weight (T):

-

17 T

-

Power(KW):

-

155

-

Keyword:

-

Fast Food Packaging Box machine

-

Customization:

-

we can change it to automation package

-

Marketing Type:

-

Hot Product 2022

-

Finished product:

-

biodegradable food container machine

-

Forming Area:

-

780*650mm

-

Forming depth:

-

150mm

-

Max sheet roller diameter:

-

800

-

Function:

-

Forming - Cutting - Punching-Stacking

-

Heating Oven:

-

3 sections heating

-

Certification:

-

Video technical support, Free spare parts, Field installat

Product Overview

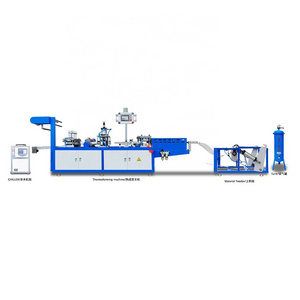

Fully Automatic Food Packaging Thermoforming Molding Machine

|

Device Specification

|

|

|

|

|||

|

Sheet width

|

500~750 mm

|

Max.Forming Height(mm)

|

130

|

|||

|

Sheet thickness

|

0.12~2.0 mm

|

Forming Width (mm)

|

650

|

|||

|

Forming Length

|

780 mm

|

Production Speed(Cycles/min)

|

40

|

|||

|

Max.roll diameter

|

≤800 mm

|

Type of plastic

|

Hips, PVC, PS, PP, PET

|

|||

|

Max.cutting force

|

800KN

|

Heating Power (kW)

|

116

|

|||

|

Formed depth

|

≤±130 mm

|

Dimension(L*W*H)

|

12000*2600*2600mm

|

|||

|

Voltage

|

380V/50HZ 3Ph

|

Weight

|

17T

|

|||

|

High speed, low noise, high reliability, and convenience to maintain Max. Production speed up to 50 cycles per minute, definitely can be named as high speed thermoforming machine.

|

|

|

|

|||

■

The door with toughened glass and aluminum, elegant appearance, easy to clean.

■ The surface of platens with fine grinding, and the parallelism for platens with high precision is less than 0.03mm.

■ Two movable platens (upper and lower)are adjustable in height, and it's suitable for any height of platen.

■ The Plate with assist installing device can make installing and changing mold more easy to reduce machine downtime.

■ Automatic mold locking device, faster tool change, easy to installed.

■ The aluminum alloy caterpillar track, the stress strength of chain track is huge, not easily to deformation.

■ The chain with roller guide, is running smoothly and noiseless.

■ Heating brick is made of imported heating wire and three-year warranty.

■ Cutting keeps pace with forming,precise positioning, precise Cutting.

■ Smooth operation, less noise.

■ The surface of platens with fine grinding, and the parallelism for platens with high precision is less than 0.03mm.

■ Two movable platens (upper and lower)are adjustable in height, and it's suitable for any height of platen.

■ The Plate with assist installing device can make installing and changing mold more easy to reduce machine downtime.

■ Automatic mold locking device, faster tool change, easy to installed.

■ The aluminum alloy caterpillar track, the stress strength of chain track is huge, not easily to deformation.

■ The chain with roller guide, is running smoothly and noiseless.

■ Heating brick is made of imported heating wire and three-year warranty.

■ Cutting keeps pace with forming,precise positioning, precise Cutting.

■ Smooth operation, less noise.

Sheet conveying

Controlled by servo motor,

with repeated positioning, high precision

and stable operation.

Heating system

Two heating banks (top and bottom) assembled on a single frame, sliding on prismatic guides to eliminate vibrations.Heater withCeramic heating elements and individual controllers for precise setting.

Forming station

Two movable platens (upper and lower) driven by three tie-bars for positive and negative pressure forming.Highly dynamic air valves adjusted independently achieving a higher forming speed. Quick mold locking and automatic centering.

Cutting press

Two movable platens (upper and lower) driven by four tie-bar. Cutting platens with .minimal deflection to increase knife life and process stability. Automatic locking.

Stacking system

Downward stacking,low investment and high speed.No stacking frame. Fast tool change to reduce machine downtime. Precise linear guides to prevent vibration.Ergonomic collecting with an integrated conveyor belt.

EVERY TYPES OF BLISTER PACKING

Disposable Blister plastic container has high tolerances. According to the shape and structure of the article and the weight of the tray package suitable for bearing strength, the thickness of the material used is also different, depending on the packaging needs of the packaged item.

The blister packing is often used in the food industry. electronics industry, toy industry, stationery industry, technology products industry, cosmetics industry, health care productsindustry and so on.

Recommend Products

Hot Searches