- Product Details

- {{item.text}}

Quick Details

-

Length:

-

15m

-

Color:

-

Yellow/Black

-

Application:

-

Vacuum infusion

-

Temperature Resistance:

-

120-204℃

Quick Details

-

Place of Origin:

-

China

-

Material:

-

Butyl rubber

-

Size:

-

3mm*12mm

-

Length:

-

15m

-

Color:

-

Yellow/Black

-

Application:

-

Vacuum infusion

-

Temperature Resistance:

-

120-204℃

Products Description

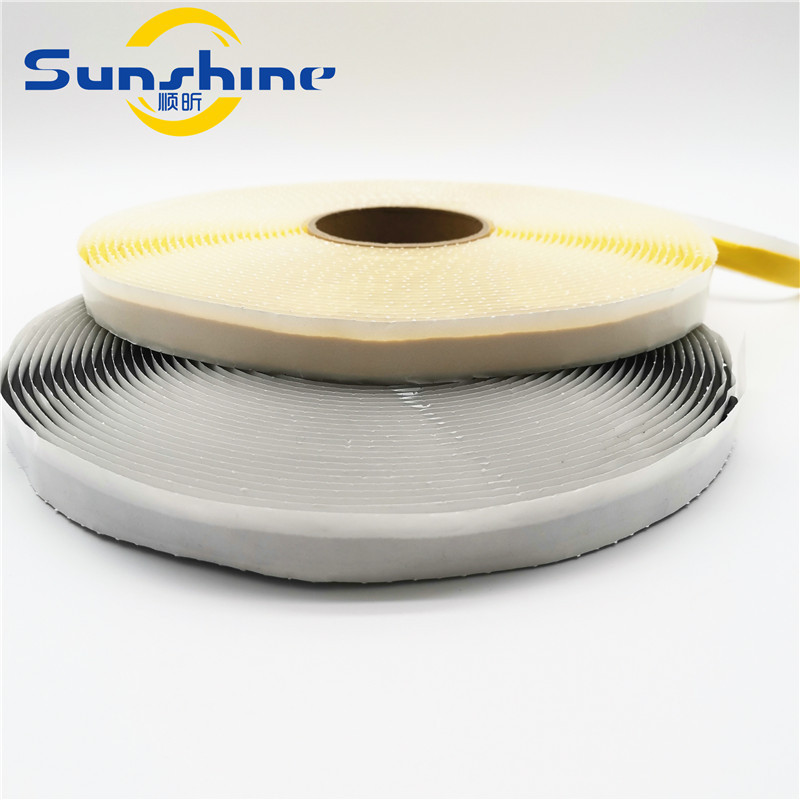

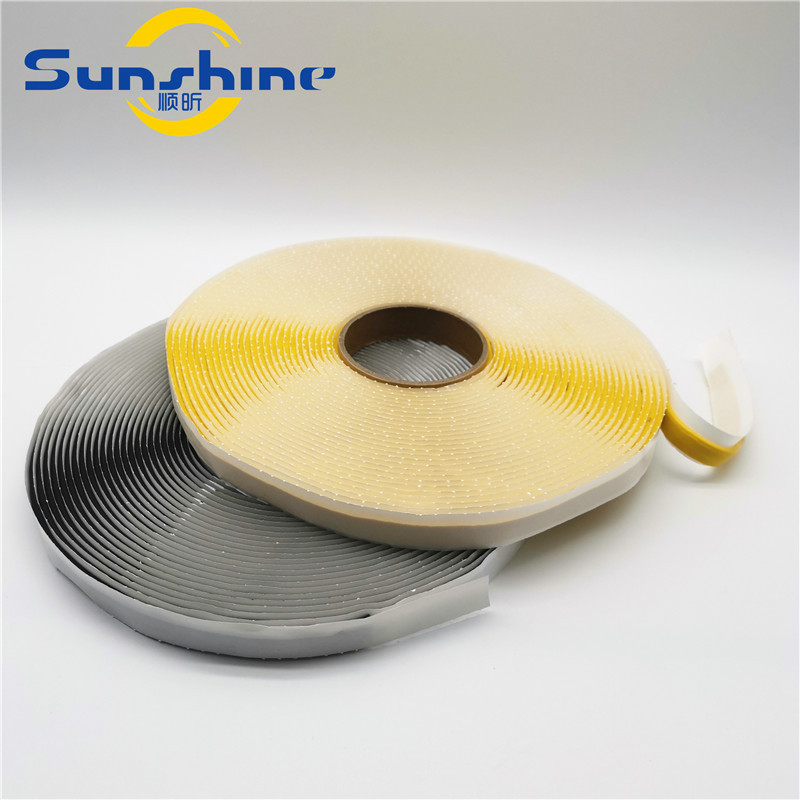

Sealant tape

is a kind of sealing material made of butyl rubber as the main material, with other additives and high quality imported special polymer materials by a special process. It is environmental solvent-free, lifelong non-curing and self-adhesive waterproof. It has strong adhesion to all kinds of surface materials as well as excellent weather resistance, aging resistance ,water resistance, sealing and vibration reduction. Because it contains no solvent at all, it does not shrink and emit nocuous gases. Because it does not solidify during its lifetime, it has excellent following property to the surface of the adhesive, which is an advanced sealing and waterproof material. In the vacuum infusion molding process, it is sealed between the vacuum bagging film and the mold. It is widely used in aviation, aerospace, shipbuilding, wind-power blades manufacturing, cabin cover manufacturing and other FRP products in composite material molding process.

Product Property

Good adhesion

Wide range of temperature

Excellent waterproof sealing and temperature resistance

Chemical corrosion resistance

No solvent, safe and environmental

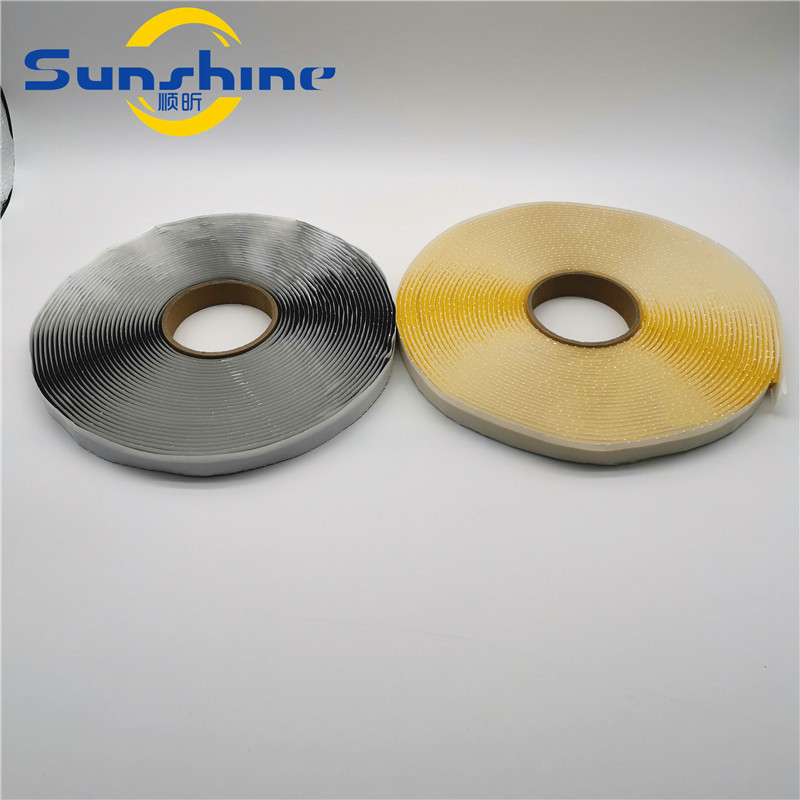

Typical Types

|

Product No.

|

Specification Thickness*Width(mm)

|

Color

|

Temp. Resistant(℃)

|

|

SXSTB120

|

3mm×12mm

|

black

|

≤120℃

|

|

SXSTY150

|

3mm×12mm

|

yellow

|

≤150℃

|

|

SXSTY204

|

3mm×12mm

|

yellow

|

≤204℃

|

Applications

With

the continuous improvement of low viscosity, low exotherm, and thermosetting resin system on manufacturing technology, the core material with good diversion performance, the vacuum resin infusion processing is gradually widely used in composite materials production, so as to achieve the desire of improving FRP product quality, maintaining the integrity of its structure, reducing weight, and reducing overall costs becomes possible. This process has been successfully applied to large wind blades and nacelle covers, train head covers, safety helmets, yachts, ship, sports equipment, etc.

Vacuum Infusion processing is a new type of low-cost composite material large-scale forming technology, which eliminates the air of fiber reinforcement materials under vacuum, the use of auxiliary materials can help exhaust excess air, control the resin flow well, achieve impregnation to the fibers and fabrics, so that it can be cured successfully and perfectly.

Packing and Shipping

PACKAGING

Product is manufactured in form of a roll wound on a paper tube. Each roll is packed in a plastic bag and placed within a cardboard carton. Positioned securely on to a pallet, strapped and covered.

Customized dimension and packaging also are welcome.

SHIPPING

For large cargo and not urgent needed, we recommend to ship by sea.

For urgent needed goods, by air is more suitable.

For samples, it is available to ship by DHL/Fedex/UPS/TNT/EMS or other way express

STORAGE

It is recommended that the product are stored in a cool and dry environment .

Recommended temperature range of storage is between 10-30℃ and relative humidity between 50-75%.

The product should remain in the packaging until just prior to use. Pallets should be stacked only one high.

Related Products

Why Choose Us

High quality

Processes and batch tracing management

Raw material,carton,tube stock

Quality control management

Lead time

Lead time for new customer Within 7 days for trial order

Lead time for regular customer- we have their order in scheme Within 15 days for one container order

Considerate service

Customer oriented, OEM service

We accumulated rich experiences in client service

Deal with customer feedback within 24 hours

We take responsibility for every batch of products shipped out

Hot Searches