Widely used in grain, food, feed, chemical and other fields of granular, powder material vertical transport.

- Product Details

- {{item.text}}

Quick Details

-

spare parts:

-

one year for free

-

color:

-

red,green,white or according the custome's damand

-

after-sales service:

-

lifetime

-

capacity:

-

5ton per hour

-

quality guarantee:

-

one year

Quick Details

-

Place of Origin:

-

Hebei, China

-

Weight:

-

8000 kg

-

prduct name:

-

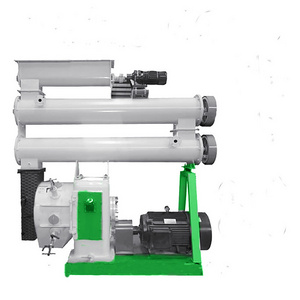

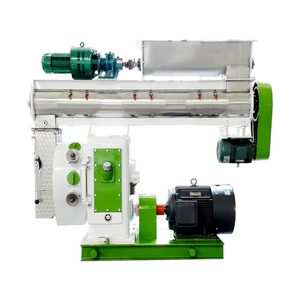

SZLH Ring Die Poultry Feed Pellet Mill

-

spare parts:

-

one year for free

-

color:

-

red,green,white or according the custome's damand

-

after-sales service:

-

lifetime

-

capacity:

-

5ton per hour

-

quality guarantee:

-

one year

SZLH Ring Die Poultry Feed Pellet Mill

SZLH series C type pelleter with the international advanced level, the latest technology, low failure models.

On the basis of the A type ring die pelleter, the feeding of the raw material added steam quenching and tempering deviceis and it is controlled by the variable speed motor, the feeding is uniform and convenient.

With large stainless steel steam modulator, conditioning, curing time is long.

Can be equipped with single, double, multi-layer jacket modulator or dual-axis differential modulator, to meet the production of high-grade livestock and poultry materials and aquatic products of different needs.

Transmission parts using high-strength belt drive, smooth operation, low noise.

Rotary parts of the selection of high-quality bearings, to ensure high-speed rotation stability.

The addition of a permanent magnet to the cutting part of the device, increasing the service life of the main components while reducing the same type of auxiliary equipment.

Easy operation, reliable sealing, high production efficiency, low energy consumption, low labor intensity.

pellet mill machine 5 ton per hour / poultry feed mill business plan

Shijiazhuang Huanpai Machine Co.,Ltd is a professional manufacturer of all types of animal feed pellet machine.

We are manufacturing animal feed production line, fish feed production line, pet feed line, poultry feed line, livestock feed plant, chicken feed pellet plant, cattle feed pellet plant, pig feed pellet plant, sheep feed pellet plant etc., and our all products have got CE and ISO9001:2000 Certificate.

The animal feed pellet production line is manufactured to produce feed pellets. It mainly includes Cylinder filtering sieve, Hammer mill, Mixer, Feed pellet machine, Cooling, Crumbler machine, Rotary screener, Packing machine. It has advantages such as compact structure, good appearance, high yield, less consumption, convenient and reliable performance etc.

Main single machine

TDTG series scoop elevator

Raw materials receiving and pre-cleaning system

Their materials will be store in store godown. According to requirement these material will be

dumped manually in dumping hopper and conveyed to the pre-cleaner through the mechanical conveyor system.

Crushing system of feed pellet product line

grinding material can transfer his maximum energy to the animal as compare to a course grinded material. It is a very energy consuming process.

Mixing system of feed pellet product line

.

Pelletizing system of feed pellet product line

Feed pellet machine is a main step of any pelleting plant. It is a process of converting any powder to solid shape called pallet. In this process the powder material is extruded through a well designed die with the help of rollers to convert it in to pallets. The quality & production of pallet mill depends on so many parameters.

Cooling system of feed pellet product line

Crumbling system of feed pellet product line

Rotary screener system of feed pellet product line

Packing system of feed pellet product line

Electric control system

It provides reliable protetion for machines and wires and automatic alarm in case of machine failure.It indicates the rechnological flow and visibly exhibits the running state of all machines on the simulating screen.

Acxessooy machines

Impeller Feeder,Pneumatic tee,Pneumatic gates,Electric tee,air seal machinery,ring die etc

Final Products

Our equipment can produce all kinds of animal feed.We are responsible for the installation and debugging of equipment and training of workers.At the same time can provide customers with feed formula

Main Features

1. Wide applicable scope

It can process different materials such as corn, maize, grass, grain, SBM, MBM, alfalfa, molasses, straw, and some other raw materials.

2. Complete feed pellet process

Animal feed pellet production line contains receiving and cleaning, grinding, batching and mixing, pelletizing,cooling,

crumbling ,screening and packing pellets parts. Full line

contains crusher, mixer, pellet mill, cooler,crumbler,cooler and all bins, screener,packing machine conveyors etc.We will design the full pellet line flow chart according to your

raw materials and specific requirement.

3. Good quality finished feed pellets

Stainless steel conditioner extends the conditioning and cooking time. Axial steam spraying port, improving feed

cooking efficiency.

4. High efficient feed machines

High precision driving main gear and pinion shaft adopt the carbonizing quenching and hard tooth surface grinding

technology, resulting in smooth driving, low noise and long service life.

5. Customized Capacity:

We can customize the different capacities from 1 ton per hour to 50 ton per hour or even more.

6. Different kinds and size of feed

We can customize solution of producing mash feed, pellet feed, crumble feed for you. The size of pellet feed can be 1.5mm to 18mm.

Our products are exported to more than 30 countries in the world. For example: Australian, America, Algeria, Angola, Burkina Faso, Belgium, Canada, Congo, Cameroon, Ghana, Egypt, Philippines, Libya, Zambia, Kenya, Ethiopia, , Yemen, Malawi, Tanzania, Tajikistan, Afghanistan, Vietnam, Israel, Mozambique, South Africa, Sudan, Somalia, Togo, Uganda, Uzbekistan, Tajikistan, Rwanda, Kazajastan and other country.

FAQ

Your don't need to worry anything, Our professional Chinese engieer will go to you country to help you install the machinery and train workers.

* Training how to install the machine, training how to use the machine,maintainenance.

* Engineers available to service machinery overseas.Providing professional support for the consultation of engineering technology and technical problem.

3. How do you control the quality?

We insist "Expertise create infinite" and always pay great attention to quality control from the very beginning to the end. You can also be reassured by our one-year warranty and CE&BV&SGS Certificates.

4. Can you provide turn-key project?

Yes, we have enough experience in installing turn-key projects overseas.

4. Where is your factory located? How can I visit there?

Our factory is located in Shijiazhuang City, Hebei Province, China, near Beijing. You can fly to Beijing airport directly.Welcome to visit our factory any time!

Installation services

An experienced engineer will be send to project site to ensure the successful completion of each phase of the plant, which enables us to provide professional consultation, design, manufacture, installation and project management services.

|

SHIJIAZHUANG HAUNPAI MACHINE CO., LTD

|

|

|

|

|||

|

Contact Person:

|

Hussein Ali

|

|

|

|||

|

Mobile(WhatsApp)

|

0086 13722990009

|

|

|

|||

|

Email:

|

flourmill at 126.com

|

|

|

|||

SZLH Ring Die Poultry Feed Pellet Mill SZLH Ring Die Poultry Feed Pellet Mill SZLH Ring Die Poultry Feed Pellet Mill SZLH Ring Die Poultry Feed Pellet Mill SZLH Ring Die Poultry Feed Pellet Mill SZLH Ring Die Poultry Feed Pellet Mill