- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Apartment

-

Place of Origin:

-

Jiangsu, China

-

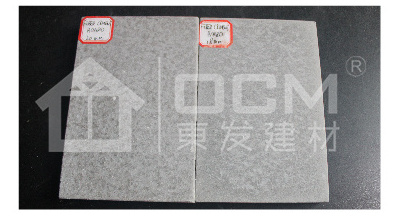

Brand Name:

-

OCM

-

Model Number:

-

FCB0009

-

Max Width:

-

1220mm

-

Max Length:

-

3050mm

-

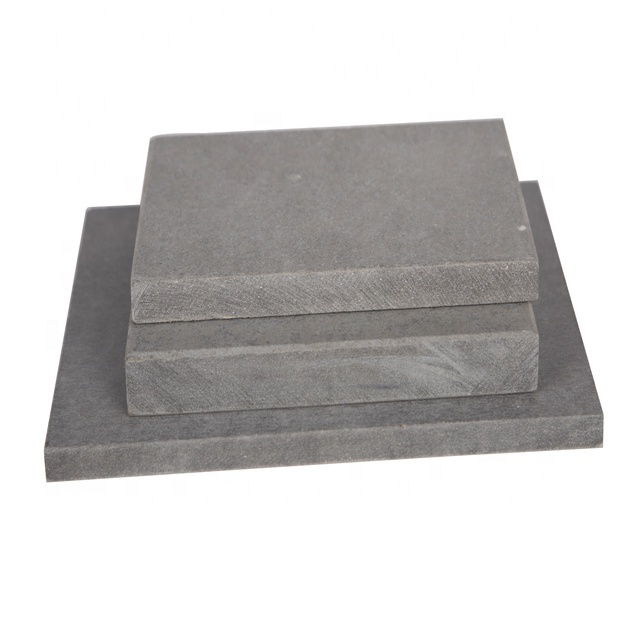

Thickness:

-

3-25mm

-

Density:

-

1.1-1.6kg/cm3

-

Color:

-

Grey/Black/Yellow/Red/White

-

Raw Materials:

-

Reinforced fiber, cement, quartz sand

-

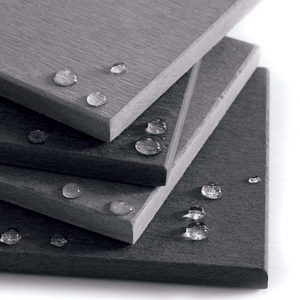

Formaldehyde release:

-

No Formaldehyde

-

Advantage:

-

Fire Resistance Incombustibility A Class

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Onsite Training

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Apartment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OCM

-

Model Number:

-

FCB0009

-

Max Width:

-

1220mm

-

Max Length:

-

3050mm

-

Thickness:

-

3-25mm

-

Density:

-

1.1-1.6kg/cm3

-

Color:

-

Grey/Black/Yellow/Red/White

-

Raw Materials:

-

Reinforced fiber, cement, quartz sand

-

Formaldehyde release:

-

No Formaldehyde

-

Advantage:

-

Fire Resistance Incombustibility A Class

| Standard Specification | |

| 1200*2400*4-20mm | Selectable other specifications Selectable abrasive finishing on right surface |

| 1220*2440*4-20mm | |

| 1220*2745*4-20mm | |

| 1220*3050*4-20mm | |

| Size | Max Width: 1220mm | Max Length:3050mm | Thickness:4mm-20mm |

| Edge Type |

Square Edge |

Beveled Edge |

Tapered Edge |

| Product name |

Density

(g/cm3) |

Antiflex cracking strength

Mpa

|

Water absorption rate

%≤ |

Water impermeability |

Freezing resistance |

Incombustibility | Radioactivity |

| Fiber cement board | 1.1~1.4 | 14 | 35 | After 24 hours of water immersion, no water droplets appear on the bottom surface | 25 cycles of freeze-thaw, no delamination, etc. | Conforming to GB8624 A Class | Conforming to GB6566-2001 A Class |

| 1.4~1.7 | 18 | 26 |

| 1. Top Track | 2. Floor Track | 3. Metal Studs | 4. Horizontal Keel |

| 5. Tapping Screw | 6. Expansion Bolt | 7. OCM Board | 8. Concrete Skirting Board |

Partition Installing Method

Galvanized Metal Frame

1.The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

2.The vertical keel should be aligned well according to the requirement (generally being 612 mm) with laterally supporting keel installed.

Board Material Package Fixed

1.Cutting the board material to the dimensions needed (about 10mm lower than wall height)

2.Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250mm with screws sinking 0.5mm under the board face.

3.The expansion seam of about 4mm between boards should be kept.

4.The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously

to avoid generating inner stress to make board material bucking.

5.Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.