- Product Details

- {{item.text}}

Quick Details

-

Size:

-

320 X 260 X 160mm

-

Application:

-

Golf Cart/ RV/ Marine/ UPS/ Portable B

-

Warranty:

-

3 Year

-

Cycle life:

-

5000 Times

-

Battery type:

-

lifepo4

-

Composed Type:

-

48V modularized with Built-in BMS

-

Color:

-

Green

-

Capacity:

-

30Ah

-

Cell:

-

prismatic

Quick Details

-

Model Number:

-

Lifepo4

-

Brand Name:

-

E-BAK

-

Place of Origin:

-

Jiangsu, China

-

Size:

-

320 X 260 X 160mm

-

Application:

-

Golf Cart/ RV/ Marine/ UPS/ Portable B

-

Warranty:

-

3 Year

-

Cycle life:

-

5000 Times

-

Battery type:

-

lifepo4

-

Composed Type:

-

48V modularized with Built-in BMS

-

Color:

-

Green

-

Capacity:

-

30Ah

-

Cell:

-

prismatic

Product Description

Specification

The LFP-48V-13AH-S module offers simple “plug and play” replacement for typical lead-acid battery applications. The LFP Series is ideal for robotics & autonomous vehicles looking for lightweight and long runtime. Over 100,000 batteries are currently in service within numerous industrial products such as medical carts, personal transporters (Segway), robots, autonomous vehicles, and electric floor scrubbers. Excellent float and cycle life results in low operating costs, providing a fast return on investment for end user applications.

Features

• Thousands of cycles under normal conditions

• Built-in automatic protection for over-charge, over-discharge, and over-temperature conditions

• No external battery management system required

• It supports series and parallel connection, up to Max. 6pcs battery modules in series.

• Communication via an RJ45 connection

• Maintenance free

• LED battery status indicator

• Exceptional voltage stability

• Can be charged using most lead-acid chargers

• Optional Battery Discharge Indicator (BDI) for SOC display and fault indication

• Automatic inter-module balancing with BDI

• Support LCD or Bluetooth interface

Features

• Thousands of cycles under normal conditions

• Built-in automatic protection for over-charge, over-discharge, and over-temperature conditions

• No external battery management system required

• It supports series and parallel connection, up to Max. 6pcs battery modules in series.

• Communication via an RJ45 connection

• Maintenance free

• LED battery status indicator

• Exceptional voltage stability

• Can be charged using most lead-acid chargers

• Optional Battery Discharge Indicator (BDI) for SOC display and fault indication

• Automatic inter-module balancing with BDI

• Support LCD or Bluetooth interface

|

Specification

|

LFP-48V-30AH-S

|

|

Nominal Voltage

|

48V

|

|

Nominal Capacity

|

10-30Ah

|

|

Internal Resistance

|

≤20mΩ

|

|

End of charge Voltage

|

58.4V

|

|

End of charge Current

|

≤0.02C(2.0A)

|

|

End of discharge Voltage

|

8.0V

|

|

Charge Method

|

20A CC/CV

|

|

Max. Continuous charge current

|

30A

|

|

Max. Nominal Discharge Current

|

100A

|

|

Max. Pluse Discharge Current

|

150A/1minute

|

|

Capacity@20A rate

|

≥120Ah

|

|

Cycle Life

|

≥2500cycles or 3years

|

|

Weight

|

10kg

|

|

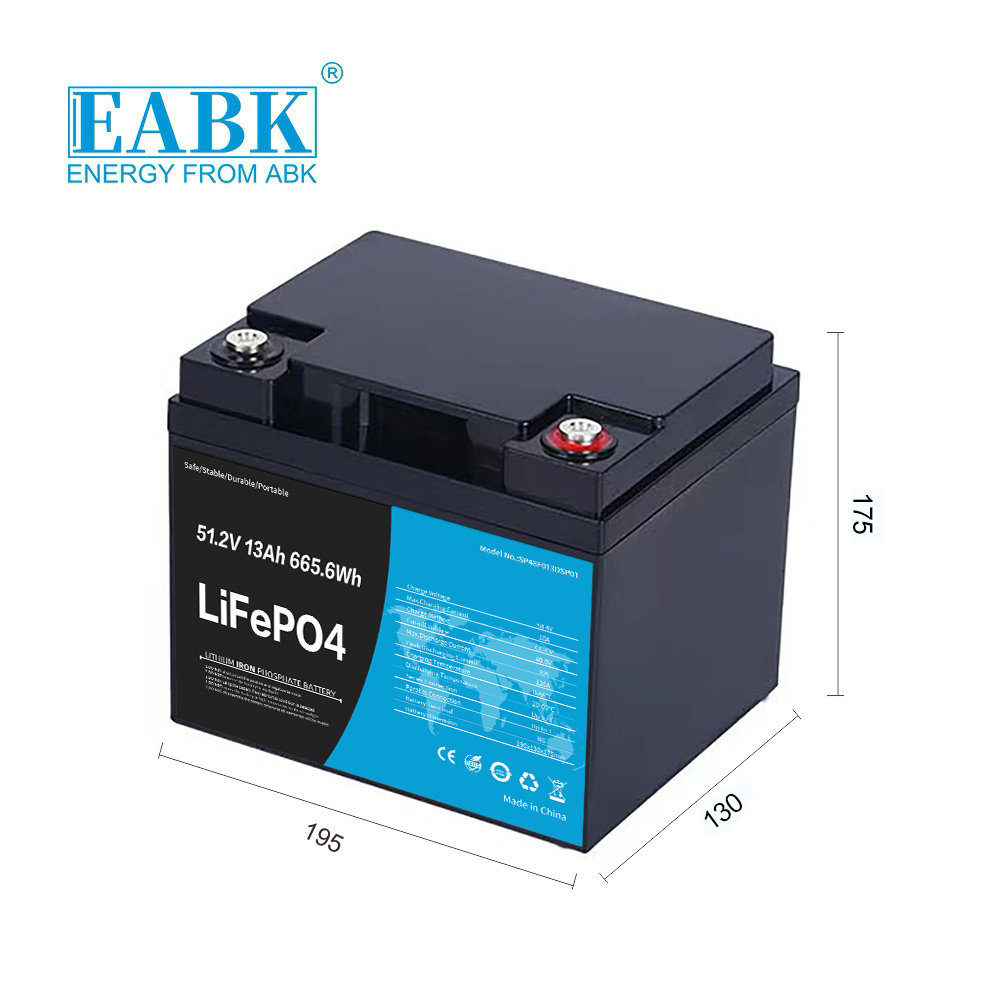

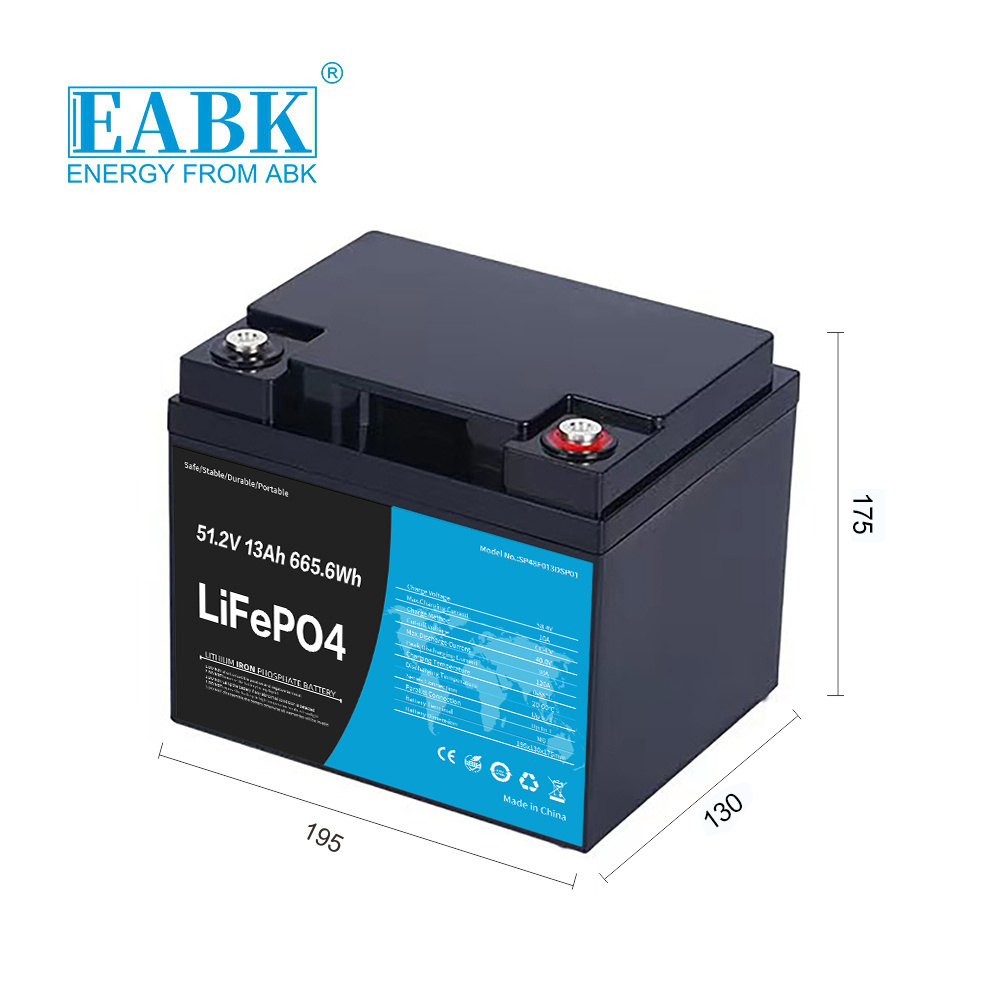

Dimension(D×W×H)

|

195 X 130 X 175mm

|

|

Part Number

|

4813001

|

Title goes here.

Battery Testing & Quality Control:

EBAK utilizes first article inspection practices as well as on-line inspection, depending on the complexity of the battery. Every battery is 100% tested for functionality before it is submitted to final inspection. This ranges from a voltage and polarity test for batteries to pull testing for any battery with wire leads and connector, and to a charge / discharge system test for rechargeable batteries. Every battery is functionally tested, especially batteries containing communication circuitry, to make sure that the battery is fully operational. A final QC inspection is performed before the battery is packaged for shipment.Whatever the customer needs is for quality verification; Superpack can meet or exceed them.

EBAK utilizes first article inspection practices as well as on-line inspection, depending on the complexity of the battery. Every battery is 100% tested for functionality before it is submitted to final inspection. This ranges from a voltage and polarity test for batteries to pull testing for any battery with wire leads and connector, and to a charge / discharge system test for rechargeable batteries. Every battery is functionally tested, especially batteries containing communication circuitry, to make sure that the battery is fully operational. A final QC inspection is performed before the battery is packaged for shipment.Whatever the customer needs is for quality verification; Superpack can meet or exceed them.

Packaging Transportation

Why Choose Us

Cooperation

Hot Searches