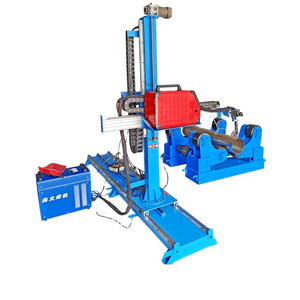

Straight seam welding is used to weld the vertical seam of the cylinder to the vertical seam of the plate.Suitable for gas shielded welding and argon arc welding autolysis (wire filling) and other welding methods.The workpiece is compressed by air bag type mechanism, and the full-length range of the workpiece is in full contact with the welded copper strip after compaction, so as to realize single-side welding and two-side molding to ensure the welding quality.It has a shielding device to protect the workpiece from deformation in the welding process, and the reverse weld is beautiful in shape.The equipment adopts PLC control to realize automatic welding operation!

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Current:

-

Customized

-

Rated Capacity:

-

Customized

-

Dimensions:

-

3234*2045*1935

-

Name:

-

Longitudinal Seam Welding Machine

-

Welding Material:

-

Aluminum

-

Function:

-

Steel Tank Welding

-

Type:

-

Arc Welding

-

Working mode:

-

Auto Longitudinal Seam Welder

-

Material:

-

Stainess Steel

-

Color:

-

Customer's Require

-

Welding Thickness:

-

1mm-8mm

-

Level:

-

Semi-auto Machine

-

Welding Speed:

-

0.15~1m/min

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

TOPRESS

-

Weight (KG):

-

1000

-

Voltage:

-

380V/220V

-

Current:

-

Customized

-

Rated Capacity:

-

Customized

-

Dimensions:

-

3234*2045*1935

-

Name:

-

Longitudinal Seam Welding Machine

-

Welding Material:

-

Aluminum

-

Function:

-

Steel Tank Welding

-

Type:

-

Arc Welding

-

Working mode:

-

Auto Longitudinal Seam Welder

-

Material:

-

Stainess Steel

-

Color:

-

Customer's Require

-

Welding Thickness:

-

1mm-8mm

-

Level:

-

Semi-auto Machine

-

Welding Speed:

-

0.15~1m/min

Contacts: David Liu

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: Liu@weldcnc.com

Mob/Whatsapp: +86 133 9411 0095

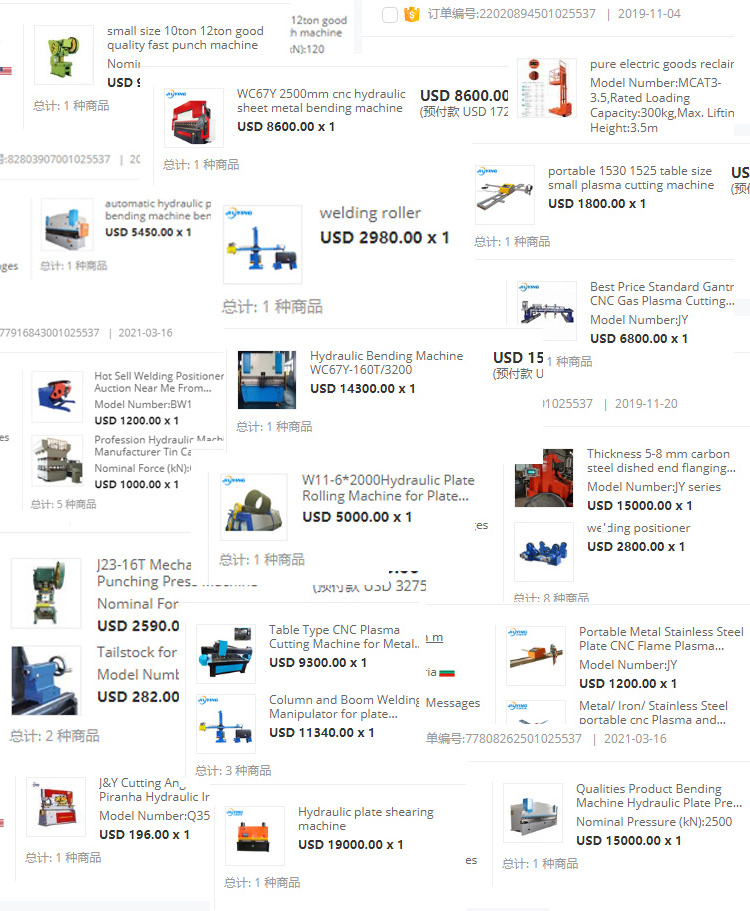

Our order and visitors

Since its establishment, Dalian J&Y Machinery Co., Ltd. has been adhering to the enterprise spirit of "pursuing excellence and exceeding expectations", insisting on improving user satisfaction and its own service level, receiving customers with high-level and convenient services, and devoting This kind of demand has won unanimous praise from customers.

Product Description

Longitudinal Seam Welding Machine

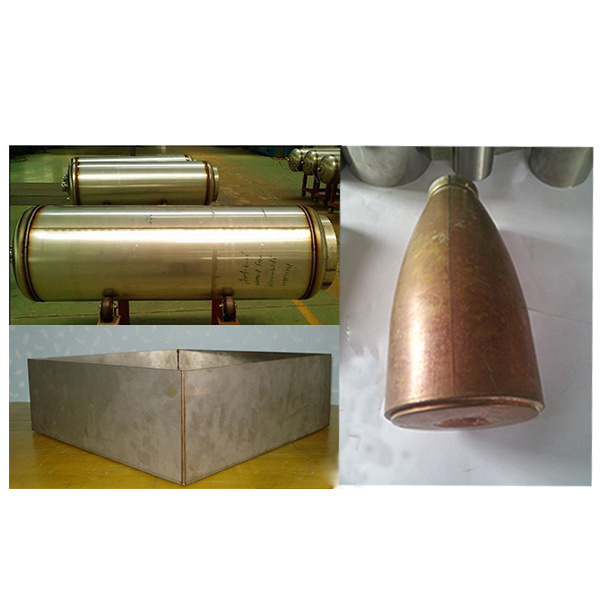

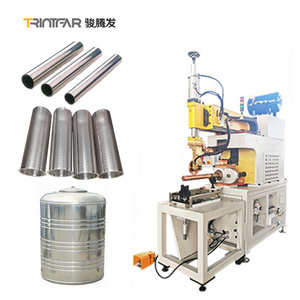

APPLICATION

Straight seam welding machine is professionally used for straight seam welding of various metal products. It has strong maneuverability, simpleness, convenience and reliability. It has smooth welding, good consistency, high efficiency and beautiful weld seam. Widely used in the straight seam welding of stainless steel kettles, stainless steel soya milk buckets, buckets, water towers, kitchen utensils, home appliances, sheet metal, pressure vessels and other hardware products.

PERFORMANCE

The longitudinal seam welding for the cylinder is docked with the longitudinal seam of the flat plate. It is suitable for various welding methods such as gas shielded welding and

argon arc welding autolysis (illing). The workpiece adopts the airbag type pressing mechanism. After pressing, the full-length range of the workpiece is fully contacted with the welding copper strip, and the single-sided welding is realized, and the two sides are formed to ensure the welding quality. There is a back gas protection device to protect the workpiece from deformation during welding and the appearance of the reverse weld. The equipment adopts PLC control to realize automatic welding operation.

Hot Searches