- Product Details

- {{item.text}}

Quick Details

-

Theoretical Shot Volume(cm³):

-

70 cm³

-

Injection Rate (g/s):

-

1 g/s

-

Injection Weight (g):

-

70 g

-

Screw Speed (rpm):

-

0 - 260 rpm

-

Screw diameter (mm):

-

28 mm

-

Weight (KG):

-

1350 kg

-

Place of Origin:

-

Henan, China

-

Open Stroke(mm):

-

220 mm

-

Model Number:

-

ORME-150ST,ORME-200STK,ORME-550C,ORME-850C

-

Brand Name:

-

ORME

-

Power (kW):

-

5 kW

-

Product name:

-

Inejction Molding Machine

-

After-sales Service Provided:

-

Online Support

-

Function:

-

Plastic Injection Molding Machinery

-

Application:

-

PLASTIC ITEMS PRODUCING

-

Used for:

-

Plsatic Production Making

-

Structure:

-

Vertical Injection Molding Machine

-

Advantages:

-

High Working Efficiency

-

Material:

-

Stainless Steel

-

Quality:

-

High-quality

-

Key Words:

-

Vertical Injection Molding Machine

Quick Details

-

Mold Height(mm):

-

45 - 220 mm

-

Ejector Stroke(mm):

-

180 mm

-

Ejector Force(kN):

-

35 kN

-

Theoretical Shot Volume(cm³):

-

70 cm³

-

Injection Rate (g/s):

-

1 g/s

-

Injection Weight (g):

-

70 g

-

Screw Speed (rpm):

-

0 - 260 rpm

-

Screw diameter (mm):

-

28 mm

-

Weight (KG):

-

1350 kg

-

Place of Origin:

-

Henan, China

-

Open Stroke(mm):

-

220 mm

-

Model Number:

-

ORME-150ST,ORME-200STK,ORME-550C,ORME-850C

-

Brand Name:

-

ORME

-

Power (kW):

-

5 kW

-

Product name:

-

Inejction Molding Machine

-

After-sales Service Provided:

-

Online Support

-

Function:

-

Plastic Injection Molding Machinery

-

Application:

-

PLASTIC ITEMS PRODUCING

-

Used for:

-

Plsatic Production Making

-

Structure:

-

Vertical Injection Molding Machine

-

Advantages:

-

High Working Efficiency

-

Material:

-

Stainless Steel

-

Quality:

-

High-quality

-

Key Words:

-

Vertical Injection Molding Machine

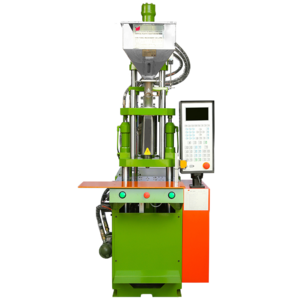

Product Description

Introduction

Injection molding machines are the main molding equipment that uses plastic molds to make various shapes of plastic products from thermoplastic or thermosetting plastics. According to the arrangement of injection devices and mold locking devices, they can be divided into vertical, horizontal, and vertical horizontal composite types. The injection molding machine heats plastic and applies high pressure to the molten plastic, causing it to shoot out and fill the mold cavity.

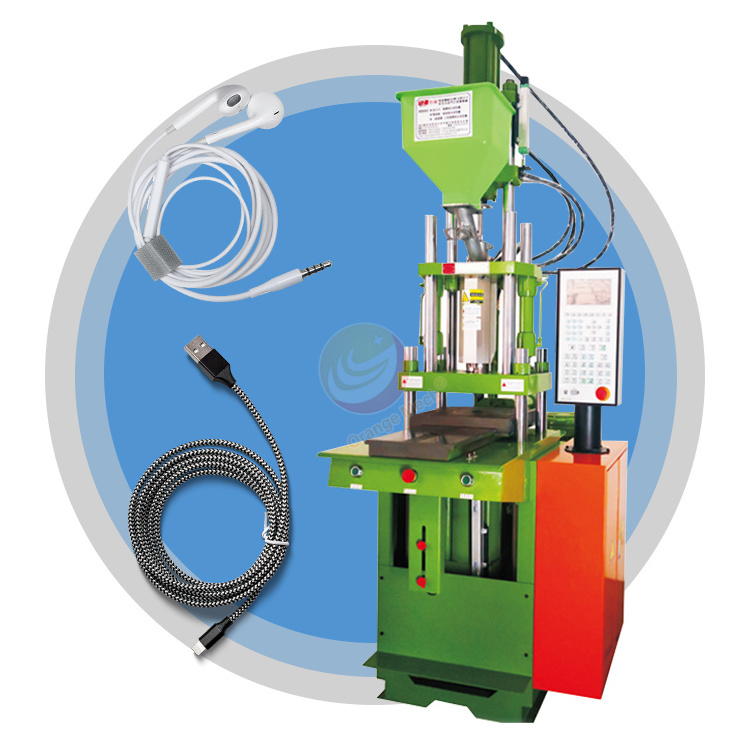

Application

Widely applicable industries: AC DC power cord, USB, VGA, HDMI, data cable, headphone cable, audio cable, network cable,connector, plug, zipper head, switch, socket, charger, electrical instrument lampshade, housing, accessories, badges, buttons,antenna, tool casing, daily products and other parts injection molding.

Features

1.

Electronic control components and hydraulic components adopt imported parts, which are quiet and powerful, precise and durable,

safe and worry free.

safe and worry free.

2.

Vertical injection molding, vertical locking, convenient for injection molding of inserts and multi-purpose injection molding

processes.

processes.

3.

The dual button start method requires both hands to simultaneously press the green start button to close the mold. The triple

protection of the electric eye and emergency stop and rebound ensures the personal safety of employees.

protection of the electric eye and emergency stop and rebound ensures the personal safety of employees.

4.

Multi stage temperature control, multi stage injection pressure, injection rate, and back pressure are infinitely adjustable.

Parameters

|

model

|

ORME-150ST

|

ORME-200STK

|

ORME-250ST

|

ORME-550C

|

ORME-850C

|

|

Screw diameter(mm)

|

25/26

|

26/28

|

26/28/30

|

40/42

|

42/50

|

|

Injection Pressure(kg/cm2)

|

1990/1780

1780 |

1920/1630

|

1920/1680/1520

|

1680/1400

|

1580/1450

|

|

Ejection volume(g)

|

45/55

55 |

55/65

|

65/70/75

|

200/250

|

250/315

|

|

Screw stroke(mm)

|

120

|

120

|

120

|

190

|

200

|

|

Screw speed(turn)

|

0-230

|

0-250

|

0-260

|

0-230

|

0-230

|

|

Number of temperature control(snt)

|

2/3

|

2/3

|

3

|

3/4

|

3/4

|

|

Locking force(tons)

|

15

|

20

|

35

|

55

|

85

|

|

Template size(mm)

|

440*280

|

485*310

|

540*380

|

680*280

|

700*350

|

|

Mold column spacing(mm)

|

290

|

340*160

|

375*205

|

/

|

/

|

|

Min mold thickness(mm)

|

45

|

75

|

80/140

|

190

|

220

|

|

Mold opening stroke(mm)

|

170

|

175

|

180

|

225

|

225

|

|

Max mold opening distance(mm)

|

215/265

|

250/300

|

260/320

|

415

|

445

|

|

Ejection pressure(tons)

|

2

|

2

|

2

|

3

|

4

|

|

Max hydraulic pressure(kg/cm2)

|

140

|

140

|

140

|

140

|

140

|

|

Pump output(1/min)

|

23

|

25

|

33

|

49

|

53

|

|

Motor power(kw/HP)

|

2.2/3.0HP

|

3.0/4.0HP

|

4.0/5.0HP

|

7.5/10HP

|

11/15HP

|

|

Electric heating capacity(kw)

|

2

|

2

|

2.2

|

5.5

|

6.5

|

|

Total Power(kw)

|

4.2

|

5

|

6.2

|

13

|

17.5

|

|

Machine weight(kg)

|

750

|

950

|

1350

|

4900

|

5600

|

|

Machine dimensions(m)

|

1.3*0.9*2.3

|

1.35*0.95*2.5

|

1.5*1.1*2.7

|

2.5*1.0*2.55

|

3.3*1.3*2.7

|

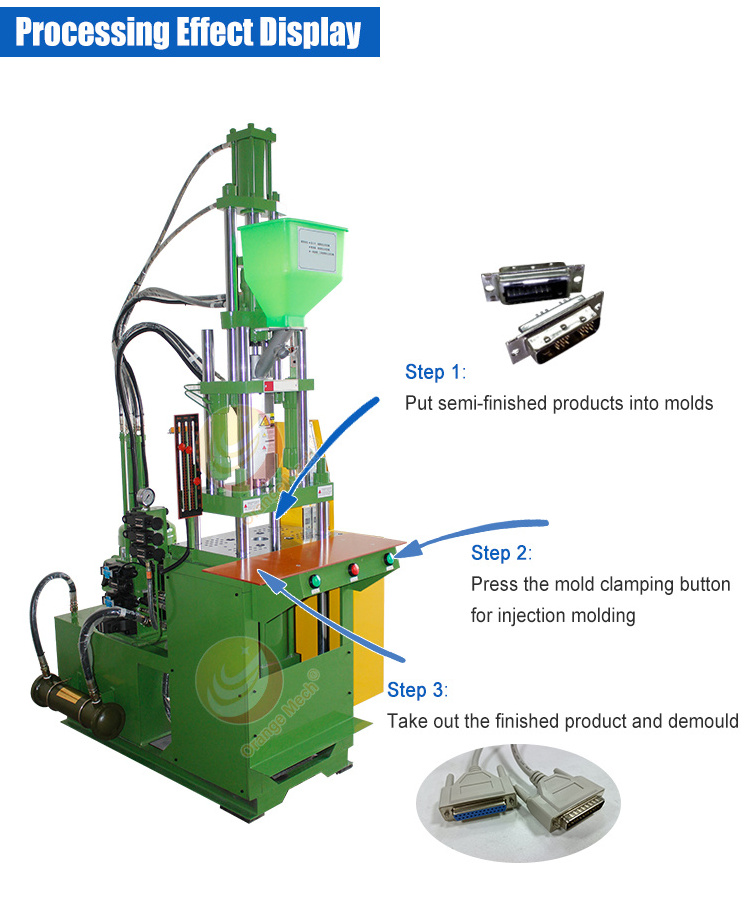

Product Details

Product Photograph

Packaging & Shipping

Install waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Hot Searches