11. Gas heated sintering furnace for curing liquid teflon and make it firmly stick on pan inside surface. For more infomation about pan coating sintering furnace please click the picture on the right.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

45.71kw

-

Dimension(L*W*H):

-

120m*3.5m

-

Weight (KG):

-

260000

-

Application:

-

teflon and ceramic coating on pan

-

production line capacity:

-

800-1200pcs/h

-

heating power:

-

gas

-

workpiece material:

-

Aluminum,cast iron

-

max workpiece weight:

-

5000g

-

max workpiece:

-

Dia360mm

-

convey method:

-

ground orbit convey

-

spray booth:

-

2 spray room

-

spray guns quantity:

-

10pcs

-

project cover:

-

400㎡, H4.5m

Quick Details

-

Machine Type:

-

teflon coated cookware production line, Spray Booths, Painting Equipment, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dwell

-

Voltage:

-

380v

-

Power:

-

45.71kw

-

Dimension(L*W*H):

-

120m*3.5m

-

Weight (KG):

-

260000

-

Application:

-

teflon and ceramic coating on pan

-

production line capacity:

-

800-1200pcs/h

-

heating power:

-

gas

-

workpiece material:

-

Aluminum,cast iron

-

max workpiece weight:

-

5000g

-

max workpiece:

-

Dia360mm

-

convey method:

-

ground orbit convey

-

spray booth:

-

2 spray room

-

spray guns quantity:

-

10pcs

-

project cover:

-

400㎡, H4.5m

Product Overview

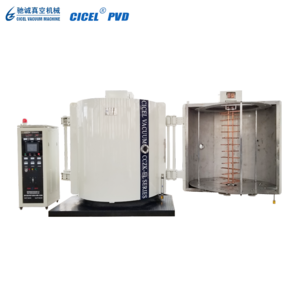

Automatic Internal Coating Machine for Manufacturing Coated Pan

This internal coating machine will work with sintering furnace to become an inner surface coating plant, used for producing coated pans, pots, ovens, bakewares and other food containers, perfect for water based teflon and ceramic spray and sintering.

Proccess of teflon Internal coating machine for aluminum casting pan:

1.workpiece loading--2.automatic dust blowing--3.preheating--4.first layer coating spray--5.surface drying furnace--6.strong wind cooling--7.second layer coating--8.spot layer coating--9.flow until even--10.transfer to sintering furnace--11. coating sintering furnace

1 and2: Manual loading zone and dust removing zone: automatic dust indution with strong air blowing to make pans clean before coating, has dust filter and water tank system.

3. 18kw gas preheating zone with smoke exhaust device, total 18 meters long, prepare for first internal coating spray.

4.Automatic spray guns from Japan spray teflon coating on pan inside surface automatically and synchronously tracking, high efficiency and uniformity.

5 and 6:Natural gas heated surface drying furnace and cool by strong air. 15G burner from Italy is used and pressure valve from America is used.

7 and 8: Second layer coating booth and third spot coating booth, then go to the buffer zone for liquid coating flow to surface evenly.

9 and 10: After uniformal flow products will be transfered to entrance of sintering furnace.

Successful projects

Non stick pan production plant

Rice cooker powder coating line

Soup pot coating line

Bakeware coating machines

Rectangle grill pan coating line

Ceramic coating pan production plant

Hot Searches