- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3-phase 4-wires, 380V, 50Hz

-

Dimension(L*W*H):

-

8200*2500*2200mm

-

Power (kW):

-

30kw

-

Weight (KG):

-

9600 KG

-

Device name:

-

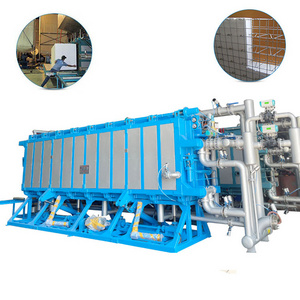

Eps Foam Plate Sheet Block moulding machine

-

Raw materia:

-

Extendable polystyrene

-

Mold size:

-

6100*1240*630

-

Product size:

-

6000*1200*600

-

Products Density Range:

-

5-33Kg/m³

-

Steam pressure:

-

0.8Mpa

-

Machine weight:

-

9600kg

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DEMENG

-

Machine Type:

-

polyurea spray, EPS Foam Sheets

-

Voltage:

-

3-phase 4-wires, 380V, 50Hz

-

Dimension(L*W*H):

-

8200*2500*2200mm

-

Power (kW):

-

30kw

-

Weight (KG):

-

9600 KG

-

Device name:

-

Eps Foam Plate Sheet Block moulding machine

-

Raw materia:

-

Extendable polystyrene

-

Mold size:

-

6100*1240*630

-

Product size:

-

6000*1200*600

-

Products Density Range:

-

5-33Kg/m³

-

Steam pressure:

-

0.8Mpa

-

Machine weight:

-

9600kg

Introduction

Longkou Demeng Machinery Equipment Co., LTD. specializes in foam packaging industry for more than 30 years, has rich industry experience, professional pre-sales and after-sales team, for customers efficient production escort。

Longkou Demeng Machinery Equipment Co., LTD. specializes in foam packaging industry for more than 30 years, has rich industry experience, professional pre-sales and after-sales team, for customers efficient production escort。

We produce EPS Vacuum Shape Molding Machine, EPS foam box machine, EPS block Molding Machine, ICF block machine, EPS outside wall thermal insulation machine,EPS intermittent automatic pre-expander machine, EPS pre-expander Machine, EPS cutting machine, EPS foam cup making machine and so on. We provide Turn-key service for EPS project.

Equipment process flow

PRODUCT SPECIFICATIONS

|

Item

|

2000

|

3000

|

4000

|

6000

|

|

Mold size(mm)

|

2040x1220x630

|

3060x1240x630

|

4080x1240x630

|

6100x1240x630

|

|

Mold size(mm)

|

2000x1200x600

|

3000x1200x600

|

4000x1200x600

|

6000x1200x600

|

|

Capacity(min/cycle)(15kg/m³)

|

12

|

15

|

18

|

18

|

|

Cavity volume(m³)

|

1.44

|

2.16

|

2.88

|

4.32

|

|

Steam pressure(MPA)

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

|

Installed weight(kg)

|

2800

|

4600

|

6000

|

9600

|

Equipment advantage

Eps foam sheet machine It makes eps foam beads to big foam block through steam heating and air cooling. With PLC and touch screen to realize full automatic production for feeding, heating, vacuum cooling, mould opening, mould closing and ejecting the foam block。

-Adopt high quality steel in the machine and combining with heat treatment to strengthen machine intensity,without changing its shape. It can bear expansibility of high intensity product.

- Adopt PLC computer touch screen to realize automatic circulation work ranged from mold open, mold close,charging,

heating,preservation, air cooling, stripping and ejection.

-Adopt special aluminum alloy plate in machine cavity, high thermal conductivity, favorable tensile strength and long lifetime.

-Adopt advanced molding technique,the machine is applicable to produce blocks ofhigh-density and low-densityand can ensure same quality of inside and outside block

- Adopt PLC computer touch screen to realize automatic circulation work ranged from mold open, mold close,charging,

heating,preservation, air cooling, stripping and ejection.

-Adopt special aluminum alloy plate in machine cavity, high thermal conductivity, favorable tensile strength and long lifetime.

-Adopt advanced molding technique,the machine is applicable to produce blocks ofhigh-density and low-densityand can ensure same quality of inside and outside block

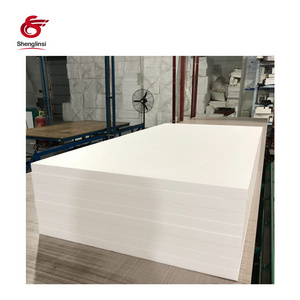

Workable product

Equipment details

Delivery photo

Our team

FAQ

1.Q:Can the product size be customized?

A:We can customize the machine according to your product size.

2.Q:How long is the equipment delivery time?

A:The delivery time is determined according to your order quantity. The delivery time of a single equipment order is 40 days.

3.Q:How about after-sales service?

A:We have a professional after-sales service team, we will also send engineers to your factory for installation and commissioning, and you can contact us at any time if you have any questions, we provide 7*24 hours after-sales service.

4.Q:Why I choose your company?

A:a) We are the Leading foam machine Manufacturer in China.

b) We have made foam machine about 30 years with strong experience and advanced technics

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

b) We have made foam machine about 30 years with strong experience and advanced technics

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

5.Q. What is an EPS box molding machine?

A. An EPS box molding machine is a machine that is used to manufacture EPS (expanded polystyrene) foam boxes, which are commonly used in the packaging industry.

6.Q. What are the advantages of using an EPS box molding machine?

A. The advantages of using an EPS box molding machine include fast production speed, low cost, and the ability to create customized packaging solutions.

7.Q. How does an EPS box molding machine work?

A. An EPS box molding machine works by heating and injecting EPS beads into a mold, which then expands and solidifies into the desired shape.

Hot Searches