- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhongxing

-

Model Number:

-

ZXAF-10

-

Marketing Type:

-

New Product 2024

-

Key Selling Points:

-

New technology,durable

-

Weight:

-

1000 KG

-

Product name:

-

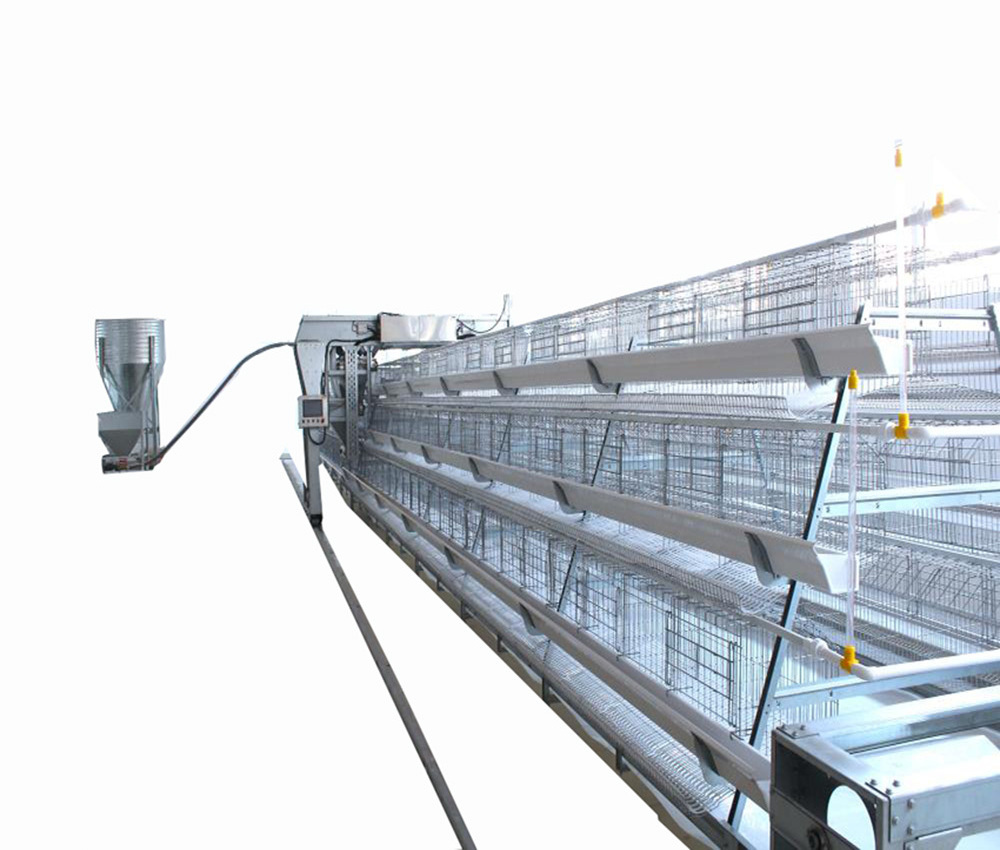

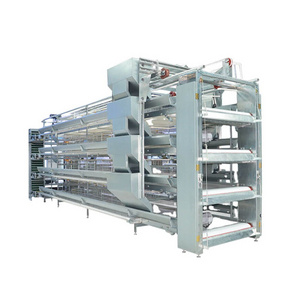

Weighing precision feed for breeding hens chicken cage

-

Capacity:

-

6-18 Feed end

-

Feeding system:

-

Automatic feeding with weight

-

MOQ:

-

1 set

-

Advantage:

-

Modern Environment Controlled Farm

-

Service:

-

Online Time

-

Egg Collecting:

-

Automatic Egg Belt

-

Manure Cleaning System:

-

Automatic Manure Belt Conveyor

-

Size:

-

Customized

Quick Details

-

Type:

-

weighing feeding machine for chicken

-

Material:

-

Hot galvanized steel, Hot Dip Galvanized Steel

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhongxing

-

Model Number:

-

ZXAF-10

-

Marketing Type:

-

New Product 2024

-

Key Selling Points:

-

New technology,durable

-

Weight:

-

1000 KG

-

Product name:

-

Weighing precision feed for breeding hens chicken cage

-

Capacity:

-

6-18 Feed end

-

Feeding system:

-

Automatic feeding with weight

-

MOQ:

-

1 set

-

Advantage:

-

Modern Environment Controlled Farm

-

Service:

-

Online Time

-

Egg Collecting:

-

Automatic Egg Belt

-

Manure Cleaning System:

-

Automatic Manure Belt Conveyor

-

Size:

-

Customized

Product Description

Advantages of automatic weighing feeder:

1.Intelligent automatic feeding, weighing and feeding, to achieve accurate feeding in the breeding process.

2.Weighing and feeding the chicken cage, PLC programming control, high degree of automation. Automatic feeding control can be

realized, and only a simple check can be done after setting.

3.It can be adjusted with the different stages of growth and development of breeding chickens, so that the feeding becomes more

reasonable and scientific, reduce the feeding cost, the breeding chickens grow healthier, and improve the average degree of breeding chickens/hens.

2.Weighing and feeding the chicken cage, PLC programming control, high degree of automation. Automatic feeding control can be

realized, and only a simple check can be done after setting.

3.It can be adjusted with the different stages of growth and development of breeding chickens, so that the feeding becomes more

reasonable and scientific, reduce the feeding cost, the breeding chickens grow healthier, and improve the average degree of breeding chickens/hens.

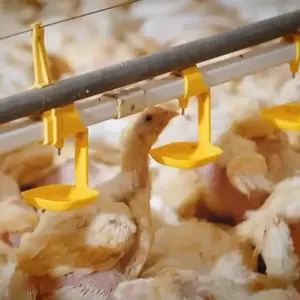

The automatic weighing precision feeding system developed by Zhongxing Livestock Machinery Co., Ltd. makes breeding chickens eat more accurately.

By controlling the amount of feed, the breeder can grow more healthily, improve the quality of egg production, the fertilization rate is greatly improved, and the eggs hatch into healthier chicks.

Automatic weighing accurate feeding system for breed hen /Cock

functional automation:

The truck automatically feeds.Usually

Chicken feed bin are

placed outside the breeding plant

Dividing box

The main bin automatically transmits food to the sub-bin placed in breeding plant each one

Feed distributor

Food is automatically transmitted from the silo to the distributor through pipes located in the breeding plant

The distributor automatically senses the feeding signal, and then stops or mechanically divides the material.

Weighing precisely Feeding machine

Auto weighing and feeding accurately machine have 6-40 weighing chips ,make the feeding precisely to each cage through

Detecting the number of chickens in each coop by

Detectors installed in this device.

From the original into the bin to put into the chicken cage trough,

All the things that should be done

are automatically controlled by PLC.

Specification

The type H or A Battery Cage can be customized by clients according to the quantity of chicken , or workshop square.The

specification is not Immutable, it is variable and elastic flexible.

specification is not Immutable, it is variable and elastic flexible.

Our Services

Customers

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Shipment and loading

FCL = Full container loading :

~MOQ: 10 sets. All cages and accessory be packed in wooden box

~20FT container can load 120 sets cages and accessory

~40ft container can load 280 sets cages and accessory

~The front mesh in one bundle, back mesh in one bundle, bottom mesh in one bundle, side mesh in one bundle

~All accessory be packed in plastic bag or cartons

~MOQ: 10 sets. All cages and accessory be packed in wooden box

~MOQ: 10 sets. All cages and accessory be packed in wooden box

~20FT container can load 120 sets cages and accessory

~40ft container can load 280 sets cages and accessory

~The front mesh in one bundle, back mesh in one bundle, bottom mesh in one bundle, side mesh in one bundle

~All accessory be packed in plastic bag or cartons

~MOQ: 10 sets. All cages and accessory be packed in wooden box

L CL=Less container loading

10 SETS IS MIN Order.

Hot Searches