- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customization

-

Dimension(L*W*H):

-

customization

-

Year:

-

2023

-

Weight (KG):

-

2300 kg

-

Power (kW):

-

customization

-

Power:

-

55KW

-

Application:

-

Tire Rubbers Recycling Industry

-

Raw material:

-

waste tires

-

Function:

-

Tire Powder Recycling Machine

-

End product:

-

powder

-

Capacity:

-

500KG/H-10tons/H

-

Motor brand:

-

China Local Famous Brand

-

Our Service:

-

On-site Installation

-

Adapt tire:

-

<1200MM

-

Color:

-

customization

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

SFC

-

Model Number:

-

customization

-

Voltage:

-

customization

-

Dimension(L*W*H):

-

customization

-

Year:

-

2023

-

Weight (KG):

-

2300 kg

-

Power (kW):

-

customization

-

Power:

-

55KW

-

Application:

-

Tire Rubbers Recycling Industry

-

Raw material:

-

waste tires

-

Function:

-

Tire Powder Recycling Machine

-

End product:

-

powder

-

Capacity:

-

500KG/H-10tons/H

-

Motor brand:

-

China Local Famous Brand

-

Our Service:

-

On-site Installation

-

Adapt tire:

-

<1200MM

-

Color:

-

customization

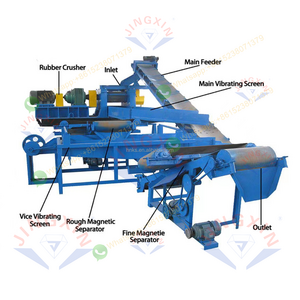

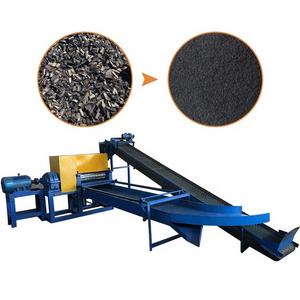

Fully automatic scrap tyre cutting R ecycle machine for 30 mesh rubber crumb/granule production line

1. Rubber powder line Description:

Full Automatic Production Line Process:

Waste Tires -→ Single Hook Debeader -→ Tire Cutter -→ Whole Tire Shredder -→ Rubber Cracker Mill -→Vibrating Screen, Belt Conveyor, Magnetic Plants -→ Fiber Separator -→ 0-30mesh rubber powder -→ Fine Rubber Powder Pulverizer -→ 30-120mesh Rubber Powder

Application:

- Waste/Used Tire Recycling Machine, Producing 500~1ton/Hour rubber powder

- Automatic tire recycle plant is used to crush the waste tire into different size of rubber powder. Environmental protection and energy saving, Market Prospect Broadness .

2.Waste tire recycle line lightspots display:

- Single Hook Debeader LSJ-1200

Usage : Pulling out the wire loops from the mouth of waste tires

Feature s:

(1) The blade of cutter is made of alloy welding and the surface is hard wear resisting.

(2) this machine have protective frame, which can effectively guarantee safety in the process of pulling out wire loop.

-

Whole Tire Cutter QDJ-1200

Usage: Cut the waste tires blocks into several parts and will be more convenient for tire shredder machine shredding.

Features: The tire blocks cutt ing machine is made up of motor, hydraulic system, oil cylinder, one pair of blade, frame and rotating body et

-

Whole Tire Shredder ZPS-900

Usage:

At the general temperature, the large tire blocks can be shredde d directly into 50*50 mm tire block s

Notes for using shredder:

main bearings use calcium-based grease lubrication, three months after the operation of the machine, the oil should be replaced and clean the fuel tank. Since then change the oil once time every year.

-

Double Rolls Tyre Crusher XK P-560

Use: Mainly used for cr ushing large rubber blocks into 0~30meshrubber powders .

Structural Features:

1. The rollers adopt alloy cold hard cast irons with wear-resisting, durable characters. The mill flour is with teeth, high groove.

2. In order to extend the service life of the cracker, we suggest build foundations for rubber cracker.

|

Model |

XKP-560 |

|

Front roll diameter |

510mm(groove one) |

|

Rear roll diameter |

560mm(smooth one) |

|

Roll working length |

800mm |

|

Front Roll Linear Speed |

25.56 m/min |

|

Speed Ratio |

1:1.30 |

|

Mai n motor Power |

55KW |

-

Tyre C

rusher

Auxiliary Equipment:

Function:

-

This whole set of auxiliary equipments includes big conveyor equipment, small conveyor equipment, big magnet separator, small magnet separator, big shaking screen, small shaking screen.

Motor Power: 16.9KW

-

Fiber Separator FS- 1100

Function :

Suitable in dealing with waste tyres, by applied in separating the fine wool out from the rubber powder got from rubber crusher to improve the pureness and quality of the rubber powder.

Motor Power: 5.5KW

3. Delivery &payment:

- Delivery lead time: 35-40 days since receiving the deposit

- Packing way:

- 1) wrapped with stretch film, avoid rubbing the paint off thesurface

- 2) wooden packaging can be customized

- 3) key parts, such as the electronic control box, will be wrapped by shockproof packaging materials, and then packed in wooden cases.

- Term of payment: T/T (30% deposit, 70% balance of B/L) ; L/C

4. Related machines:

(1) Rubber open mixing mill:

5. About us:

- Qingdao shun cheong rubber machinery manufacturing co.,ltd is a chinese manufacturer with establishment in 2007, and have 10 years experience in making various of rubber machines area, also pass the ISO 9001:2008 , SGS, CE certificates too.

- our factory major in rubber kneader/rubber mixing mill ; various of plate vulcanizing press ; 2 roll/3 roll/4 roll rubber calender; rubber batch off cooler; waste tire recycling line;reclaimed rubber production line;conveyor belt production line;rubber seals extruding &vulcanizing line etc...

- Market: our machineries have exported to America, Mexico, ndia, Vietnam, South Africa, Singapore, Malaysia, Indonisia, Australia, Sri Lanka and many other countries and regions

- Professional engineers and teams, then basing on customer requirements, we accept OEM*ODM machines, also oversea engineer service is available