- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Pow-DC-285

-

Product Name:

-

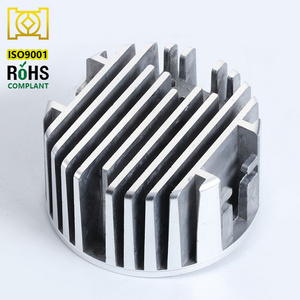

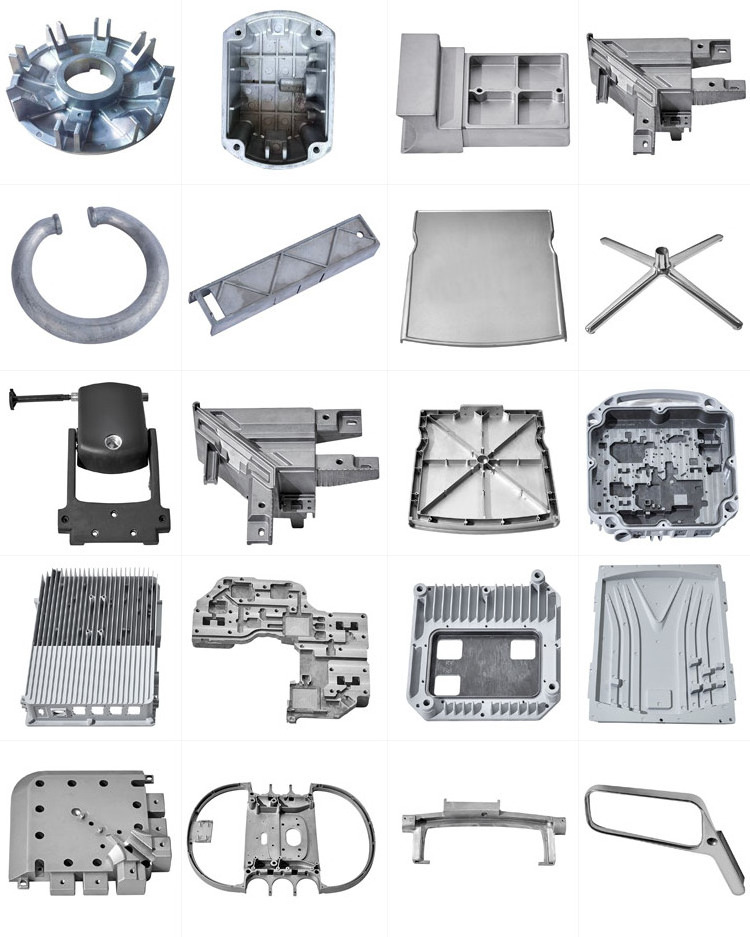

Precision Die Casting Parts / Die Casting Mold

-

Material:

-

Aluminum alloy,ADC,brass, copper, brozen, steel, Iron, stainless steel

-

Process:

-

Die Casting/sand casting/gravity casting

-

Finish:

-

Anodizing, Nickel plated, zinc plated, polishing etc

-

Secondary Machining:

-

CNC turning/milling/drilling/grinding/assembly to Packing

-

Surface treatment:

-

Painting/Anodizing/Powder coating/Electrophoresis

-

Mould material:

-

H13, 2344, 8407, 8418, SKD61, DAC, FDAC

-

Mould life:

-

100000-200000 times

-

Tolerance:

-

0.01mm

-

Service:

-

OEM ODM Customized

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

Pow-DC-285

-

Product Name:

-

Precision Die Casting Parts / Die Casting Mold

-

Material:

-

Aluminum alloy,ADC,brass, copper, brozen, steel, Iron, stainless steel

-

Process:

-

Die Casting/sand casting/gravity casting

-

Finish:

-

Anodizing, Nickel plated, zinc plated, polishing etc

-

Secondary Machining:

-

CNC turning/milling/drilling/grinding/assembly to Packing

-

Surface treatment:

-

Painting/Anodizing/Powder coating/Electrophoresis

-

Mould material:

-

H13, 2344, 8407, 8418, SKD61, DAC, FDAC

-

Mould life:

-

100000-200000 times

-

Tolerance:

-

0.01mm

-

Service:

-

OEM ODM Customized

|

Project name

|

Customizable Stamping Mould Plastic/ Die Casting Mold

|

|

Technology

|

die/sand/gravity/Low pressure die casting/Precision investment casting, CNC machining parts

|

|

Manufacture Process

|

process/secondary maching/surface Finish

|

|

Surface treatment

|

polishing, sand blasting, heat treatment, painting, powder coating

|

|

Heat treatment

|

quenching,tempering,annealing,normalizing,nitridation,carburization

|

|

Processing equipment

|

cnc machines,turning machines,driling machines,milling machines,grinding machines,ect

|

|

Measiring tool

|

cmm,projector,vemier caliper,depth caliper,micrometer,pin gauge,thread gauge,height guage,ect

|

|

Application

|

Communication equipments/mechanical equipments/Auto Parts/ Automation machine/medical device/industrial

machine/automobile/electric appliance/and other industries etc |

|

Tolerance

|

0.01mm

|

|

Weight

|

0.01-100kgs

|

|

OEM service scope

|

OEM/ODM

|

|

Drawing format

|

STEP, IGS, STEP, IGS,X_T, DWG, PDF

|

|

Packing

|

plywood or wooden case(As per customer's requirement)

|

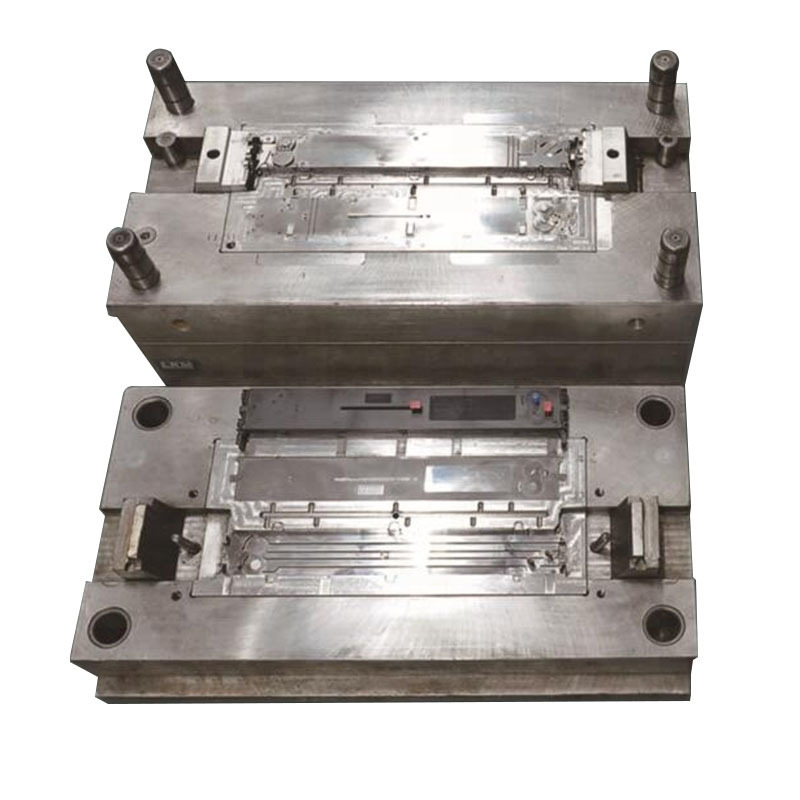

Mold Processing

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to

you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

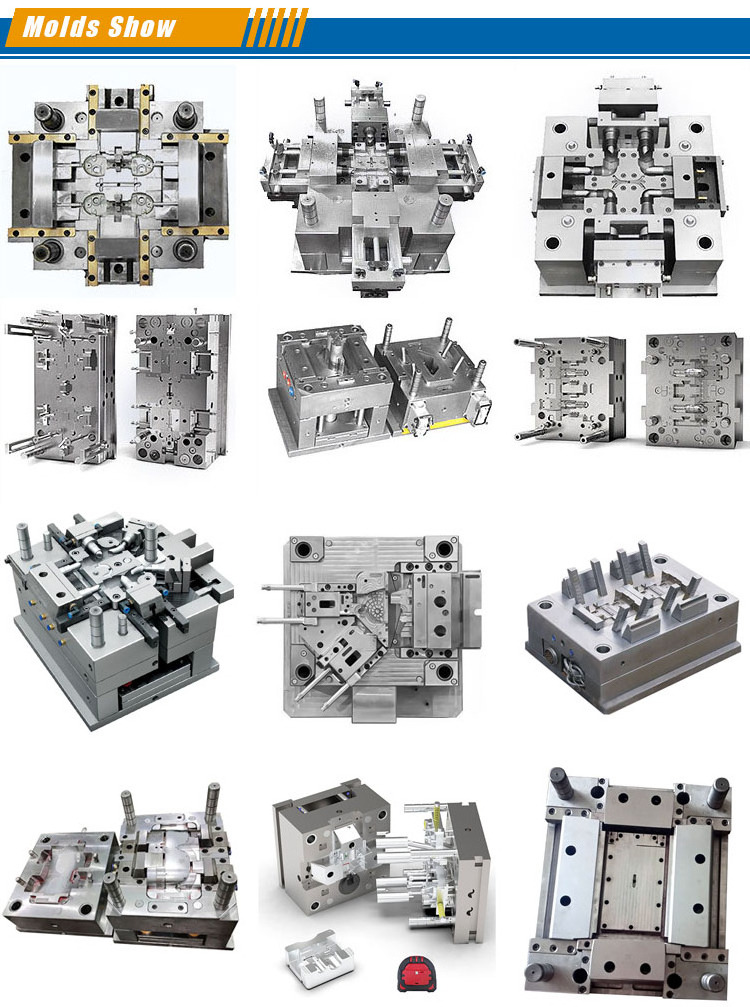

Mold Specification

1. Professional manufacturer,design,production injection mould and die casting mould quality control

2. Rich export experience plastic injection mould and die casting mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to

you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Mold Specification

1. Professional manufacturer,design,production injection mould and die casting mould quality control

2. Rich export experience plastic injection mould and die casting mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

We provides service of part design, prototype making, mold design, mold production, mass production and assembly service in house.

We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts.

1.Product & Mould Design

A professional team who are experienced in CAD/PRO-E/Moldflow/UG/etc.

2.Molding

Equips with 40 sets machines(13 sets with robot handling system and 2 sets are BI-Injection)

3.Silksreening

4.After-sales Service

Strictly follow ISO9001:2008 system, standardize components production and documentation, thus can quickly respond to customer's need.

5.Mold Manufacturing

Skillful in the fields of Automative, Electronic, Electrical, Home Appliance, Medical Device and Aerospace.

6.Spraying

7.Assembly

We are cooperating with many clients all over the world and have a deep understanding of the mold industry, our experience range from simple design to challenging technical parts.

1.Product & Mould Design

A professional team who are experienced in CAD/PRO-E/Moldflow/UG/etc.

2.Molding

Equips with 40 sets machines(13 sets with robot handling system and 2 sets are BI-Injection)

3.Silksreening

4.After-sales Service

Strictly follow ISO9001:2008 system, standardize components production and documentation, thus can quickly respond to customer's need.

5.Mold Manufacturing

Skillful in the fields of Automative, Electronic, Electrical, Home Appliance, Medical Device and Aerospace.

6.Spraying

7.Assembly

FAQ

1,Q:How many moulds could you make every month?

A:60-80 sets.

2,Q:How about the largest mould you ever made?

A:15 ton. The size is 1.8m * 1.5m.

3,Q:How about the tolerance?

A:Mould tolerance 0.005mm, Product tolerance 0.01mm.

4,Q:What is percentage of automotive moulds you made? What’s the brand?

A:About 40%. Brand: Volvo, TOYOTA,Land Rover.

5,Q:Can you make precision mould ?

A:Yes. We have made precision moulds such as moulds for medical devices.

6,Q:Can you make BI-injection mould?

A:Yes. And we have made a couple of BI-injection tools.

7,Q:Have you ever made stack mould?

A: Yes.

8,Q:How about the steel you usually use?

A:We only use raw materials with good quality like P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2767, H13,8407, 420SS, S136,

S-7. They are all from famous suppliers, such as LKM, ASSAB, THYSSEN, etc. Steel quality certificate and heat-treatment

certificate will be provided along with the tools while delivery.

9,Q:What is the standard of your hot-runner system?

A:It’s decided by the customers. We have famous hot runner suppliers locally, such as YUDO, DME, SYNVENTIVE, HASCO,HUSKY, INCOE,

EWIKON, MOULD-MASTER etc.

10,Q:What about the standard components you use?

A:We use standard components from LKM,, HASCO, DME, etc.

11,Q:What do you need for quotation? And what about the format?

A:2D & 3D part files are preferred. Or specific sample with detailed description and mould specification. We use PROE, AUTOCAD,

Acorbat Reader, Solidworks, UG and etc. All format related are acceptable.

12,Q:How long do you need for quotation?

A:Exact quotation will be available within 2 working days once we get sufficient information from customer.

13,Q:What is your turnround time for injection mould building?

A:Usually 4-8 weeks. It also depends on mould size and structure complexity.

A:60-80 sets.

2,Q:How about the largest mould you ever made?

A:15 ton. The size is 1.8m * 1.5m.

3,Q:How about the tolerance?

A:Mould tolerance 0.005mm, Product tolerance 0.01mm.

4,Q:What is percentage of automotive moulds you made? What’s the brand?

A:About 40%. Brand: Volvo, TOYOTA,Land Rover.

5,Q:Can you make precision mould ?

A:Yes. We have made precision moulds such as moulds for medical devices.

6,Q:Can you make BI-injection mould?

A:Yes. And we have made a couple of BI-injection tools.

7,Q:Have you ever made stack mould?

A: Yes.

8,Q:How about the steel you usually use?

A:We only use raw materials with good quality like P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2767, H13,8407, 420SS, S136,

S-7. They are all from famous suppliers, such as LKM, ASSAB, THYSSEN, etc. Steel quality certificate and heat-treatment

certificate will be provided along with the tools while delivery.

9,Q:What is the standard of your hot-runner system?

A:It’s decided by the customers. We have famous hot runner suppliers locally, such as YUDO, DME, SYNVENTIVE, HASCO,HUSKY, INCOE,

EWIKON, MOULD-MASTER etc.

10,Q:What about the standard components you use?

A:We use standard components from LKM,, HASCO, DME, etc.

11,Q:What do you need for quotation? And what about the format?

A:2D & 3D part files are preferred. Or specific sample with detailed description and mould specification. We use PROE, AUTOCAD,

Acorbat Reader, Solidworks, UG and etc. All format related are acceptable.

12,Q:How long do you need for quotation?

A:Exact quotation will be available within 2 working days once we get sufficient information from customer.

13,Q:What is your turnround time for injection mould building?

A:Usually 4-8 weeks. It also depends on mould size and structure complexity.

Contact Us

Contact person:Jenny LO

Tel:86-0755-26586158

Mob:0086-18925268506(WhatsApp&Wechat)

Email:jenny at powerstar-cn.com

Web:http://www.powerstar-metal.com

Skype:loujiana

Tel:86-0755-26586158

Mob:0086-18925268506(WhatsApp&Wechat)

Email:jenny at powerstar-cn.com

Web:http://www.powerstar-metal.com

Skype:loujiana

Hot Searches