- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

6000 r.p.m

-

Spindle Bore(mm):

-

63

-

Width of bed (mm):

-

405 mm

-

Spindle Motor Power(kW):

-

12/17

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

285 mm

-

Travel (Z Axis)(mm):

-

600 mm

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

4500*1850*2000mm

-

Brand Name:

-

TECHMAX

-

Model Number:

-

KL-28H

-

Voltage:

-

As per the client's request

-

Weight (KG):

-

3900

-

Marketing Type:

-

Hot Product

-

Max. cutting dia. for disc parts:

-

408 mm

-

Max. cutting dia. for axle parts:

-

260 mm

-

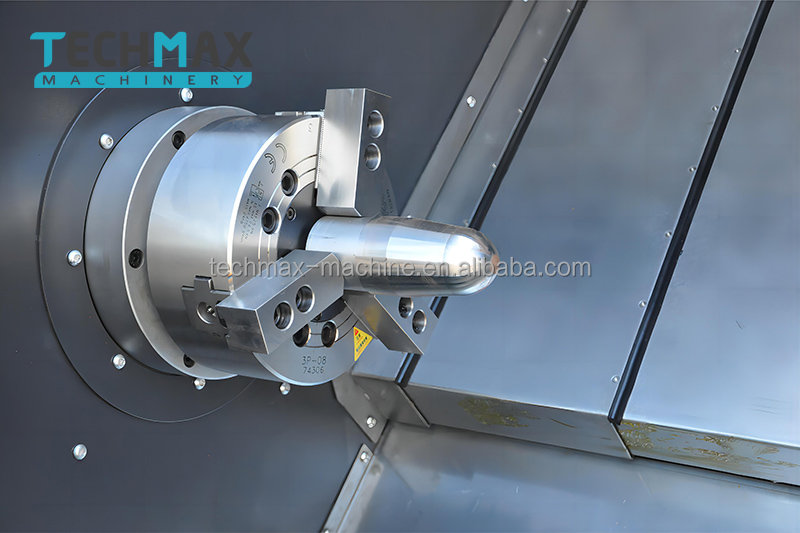

Hydraulic chuck dia.:

-

8" (200 mm); 10" (250 mm)

-

Bed structure:

-

45°

-

Tool section size:

-

20*20 mm

-

Max. tool diameter:

-

32 mm

-

X/Z-axis rapid traverse:

-

30 m/min

-

Coolant tank capacity:

-

175 L

-

Lubrication tank capacity:

-

1.8 L

-

Configuration Customization:

-

yes

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

500

-

Year:

-

custom made

-

Max. Spindle Speed (r.p.m):

-

6000 r.p.m

-

Spindle Bore(mm):

-

63

-

Width of bed (mm):

-

405 mm

-

Spindle Motor Power(kW):

-

12/17

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

285 mm

-

Travel (Z Axis)(mm):

-

600 mm

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

4500*1850*2000mm

-

Brand Name:

-

TECHMAX

-

Model Number:

-

KL-28H

-

Voltage:

-

As per the client's request

-

Weight (KG):

-

3900

-

Marketing Type:

-

Hot Product

-

Max. cutting dia. for disc parts:

-

408 mm

-

Max. cutting dia. for axle parts:

-

260 mm

-

Hydraulic chuck dia.:

-

8" (200 mm); 10" (250 mm)

-

Bed structure:

-

45°

-

Tool section size:

-

20*20 mm

-

Max. tool diameter:

-

32 mm

-

X/Z-axis rapid traverse:

-

30 m/min

-

Coolant tank capacity:

-

175 L

-

Lubrication tank capacity:

-

1.8 L

-

Configuration Customization:

-

yes

▪

CNC and drive systems produced by market leaders Siemens (Germany) and Fanuc (Japan).

▪

Chucks and spindles of leading Asian and European manufacturers.

▪

Revolver heads. engines. electric - taiwanese. Asian and European manufacturers.

▪ Beds are made of high quality cast iron. subjected to artificial aging to reduce warping.

▪ Beds are made of high quality cast iron. subjected to artificial aging to reduce warping.

▪

Possibility to optionally install Renishaw and Hexagon Tool and Parts Inspection systems.

▪

The slope of the guides avoids the accumulation of chips and facilitates access to the cutting zone.

▪ Powerful and very fast spindle. Robust turret for 12 tools. High-precision rolling guides are integrated into a one-piece cast slant bed. Modifications with driven tool.

▪ Powerful and very fast spindle. Robust turret for 12 tools. High-precision rolling guides are integrated into a one-piece cast slant bed. Modifications with driven tool.

▪

Rolling guides. bearings and ball screws of the most famous companies THK and NSK (Japan). HIWIN (Taiwan). Rexroth (Germany).

Siemens or Fanuc CNC System

3-Jaw hydraulic chuck

One-piece cast slant bed

Hydraulic tailstock

Turret with live tools

Back elevation

|

Model

|

KL-15CNC

|

KL-28CNC

|

KL-28HCNC

|

|

Swing over bed

|

Φ360 mm

|

Φ520 mm

|

Φ520 mm

|

|

Max. cutting dia. for disc parts

|

Φ250 mm

|

Φ509 mm

|

Φ408 mm

|

|

Max. cutting dia. for axle parts

|

Φ150 mm

|

Φ250 mm

|

Φ260 mm

|

|

Max. turning length

|

300 mm

|

500 mm

|

420 mm

|

|

Hydraulic chuck dia.

|

6" (152 mm)

|

8" (200 mm); 10" (250 mm)

|

8" (200 mm); 10" (250 mm)

|

|

Cross slide travel (X-axis)

|

150 mm

|

282 mm

|

285 mm

|

|

Longitudinal travel (Z-axis)

|

320 mm

|

600 mm

|

600 mm

|

|

X/Z-axis guide rails

|

type/mm

|

rolling/35.45 type/mm

|

rolling/35.45 type/mm

|

|

Bed structure

|

45°

|

45°

|

45°

|

|

X/Z-axis ball screw dia. × thread pitch. accuracy class

|

mm

|

Φ32/40×10. P3 mm

|

Φ32/40×10. P3 mm

|

|

Spindle speed

|

6000 rpm

|

4000; 5000; 6000 rpm

|

4000; 5000; 6000 rpm

|

|

Spindle taper

|

А2-5

|

А2-6

|

А2-6 тип

|

|

Spindle bore

|

Φ56 mm

|

Φ63 mm

|

Φ63 mm

|

|

Hole diameter (Hydraulic chuck)

|

mm

|

Φ52; 75 mm

|

Φ52; 75 mm

|

|

Draw pipe inner diameter (Hydraulic chuck)

|

mm

|

Φ52 mm

|

Φ52 mm

|

|

Max. bar diameter (hydraulic chuck)

|

mm

|

Φ50 mm

|

Φ50 mm

|

|

Tool station number

|

8 pcs

|

12 pcs

|

12 (driven) pcs

|

|

Tool section size

|

25×25 mm

|

25×25 mm

|

20×20 mm

|

|

Max. tool diameter

|

Φ32 mm

|

Φ32 mm

|

Φ32 mm

|

|

Live tool speed

|

rpm

|

rpm

|

5000 rpm

|

|

Drive tool power

|

kw

|

kw

|

2.2/3.7 kw

|

|

Tailstock quill taper

|

МK-4

|

МK-4

|

МK-4

|

|

Tailstock quill diameter

|

Φ80 mm

|

Φ80 mm

|

Φ80 mm

|

|

Tailstock quill travel

|

90 mm

|

120 mm

|

120 mm

|

|

Positioning accuracy

|

±0.005 mm

|

±0.005 mm

|

±0.005 mm

|

|

Repeatability

|

±0.003 mm

|

±0.003 mm

|

±0.003 mm

|

|

X/Z-axis rapid traverse

|

12/20 m/min

|

30 m/min

|

30 m/min

|

|

Coolant tank capacity

|

100 L

|

175 L

|

175 L

|

|

Coolant pump power

|

0.18 kw

|

0.18 kw

|

0.18 kw

|

|

Lubrication tank capacity

|

1.8 L

|

1.8 L

|

1.8 L

|

|

Hydraulic station power

|

2.2 kw

|

2.2 kw

|

2.2 kw

|

|

Main motor power

|

9 kw

|

12. 17 kw

|

12. 17 kw

|

|

Main motor torque

|

57 N.m

|

115. 162 N.m

|

115. 162 N.m

|

|

Overall dimensions (L×W×H)

|

2700×1460×1680 mm

|

4500×1850×2000 mm

|

4500×1850×2000 mm

|

|

Weight approx.

|

3000 kg

|

3900 kg

|

3900 kg

|

|

Standard Configuration

|

Optional Configuration

|

|

▪

Siemens 808D controller

▪ Siemens controller with a MPG unit for lathe setting ▪ 8-12 position tool post ▪ 56/63/90mm spindle bore ▪ 3 jaw hydraulic chuck 10-12 inch ▪ Alarm Lamp (3 color status light) ▪ Hydraulic station ▪ Hydraulic control pedal ▪ Coolant and lubrication system ▪ Air conditioner for electrical cabinet ▪ LED Work light

▪

Live Centre

▪ Maintenance tool kit |

▪

CNC system Fanuc 0i TF / Siemens 828D

▪ Shop Turn for Siemens 828D CNC system ▪ Hydraulic tail stock ▪ Automatic bar feeder ▪ Turret with driven tools ▪ Chip conveyor and a chip cart

▪

Driven tool holders

▪

Parts catcher

▪ Renishaw tool measuring unit |

1. How can I choose the most suitable machines ?

Re: Please tell us your specifications ,we can choose the best model for you , or you can choose the exact model . You can also send us the products drawing ,we will choose the most suitable machines for you.

2. What's your main products of your company?

Re: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Manual Lathe Machine,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on.

3. What kinds of inspection you will do for each machine?

Re: For each assembly procedure, there is geometric accuracy test. After assembly, spindle accuracy will be tested by dynamical balance testing instrument; 3 axes accuracy will be tested by Ball bar. And laser interferometer to inspect positioning and repositioning accuracy. Then the inspection team will make full test before delivery and test piece will be done on each machine. Each workpiece will be inspected by CMM, so each machine performance can be checked and kept in record.

4. Can you supply turn-key solution?

Re: Of course, we have professional team of technical service & after sale service department, who can give you the perfect solution and meet your processing requirement. Besides, we also cooperated with professional fixture company and support with us.

5. What is the warranty time of machine?

Re: We have 14 months warranty after delivery. Within the warranty period, if there is any problem not caused by wrong operation, we will supply you the replacing parts from free. Even beyond the period, we will still supply the replacing parts with cost price.

6. What is the delivery time, and what is the package?

Re: Normally the delivery time is about 45-60 days. All our machines are packed with the seaworthy wooden case/pallet, also applied with anti rust measures in advance. View drawing together if any parts disassembled.

2. What's your main products of your company?

Re: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Manual Lathe Machine,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on.

3. What kinds of inspection you will do for each machine?

Re: For each assembly procedure, there is geometric accuracy test. After assembly, spindle accuracy will be tested by dynamical balance testing instrument; 3 axes accuracy will be tested by Ball bar. And laser interferometer to inspect positioning and repositioning accuracy. Then the inspection team will make full test before delivery and test piece will be done on each machine. Each workpiece will be inspected by CMM, so each machine performance can be checked and kept in record.

4. Can you supply turn-key solution?

Re: Of course, we have professional team of technical service & after sale service department, who can give you the perfect solution and meet your processing requirement. Besides, we also cooperated with professional fixture company and support with us.

5. What is the warranty time of machine?

Re: We have 14 months warranty after delivery. Within the warranty period, if there is any problem not caused by wrong operation, we will supply you the replacing parts from free. Even beyond the period, we will still supply the replacing parts with cost price.

6. What is the delivery time, and what is the package?

Re: Normally the delivery time is about 45-60 days. All our machines are packed with the seaworthy wooden case/pallet, also applied with anti rust measures in advance. View drawing together if any parts disassembled.

Hot Searches