- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customzied

-

Dimension(L*W*H):

-

Customzied

-

Power (kW):

-

Customzied

-

Weight:

-

8000

-

Screw Speed (rpm):

-

1 - 600 rpm

-

Name:

-

plastic recycling granulator machine

-

Application:

-

Plastic Recycling Pellet Granulator

-

Certification:

-

CE/ISO/Patents

-

Final product:

-

Pellets/Granules

-

Control:

-

PLC+Touch Screen

-

Raw material:

-

HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS

-

Advantage:

-

Famous Brand Motor

-

Business type:

-

Manufacturer

-

Sample/Service Manual/Supply type:

-

Available

-

Material:

-

Tough Welded Steel

Quick Details

-

Output (kg/h):

-

320 - 2100 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACERETECH

-

Voltage:

-

Customzied

-

Dimension(L*W*H):

-

Customzied

-

Power (kW):

-

Customzied

-

Weight:

-

8000

-

Screw Speed (rpm):

-

1 - 600 rpm

-

Name:

-

plastic recycling granulator machine

-

Application:

-

Plastic Recycling Pellet Granulator

-

Certification:

-

CE/ISO/Patents

-

Final product:

-

Pellets/Granules

-

Control:

-

PLC+Touch Screen

-

Raw material:

-

HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS

-

Advantage:

-

Famous Brand Motor

-

Business type:

-

Manufacturer

-

Sample/Service Manual/Supply type:

-

Available

-

Material:

-

Tough Welded Steel

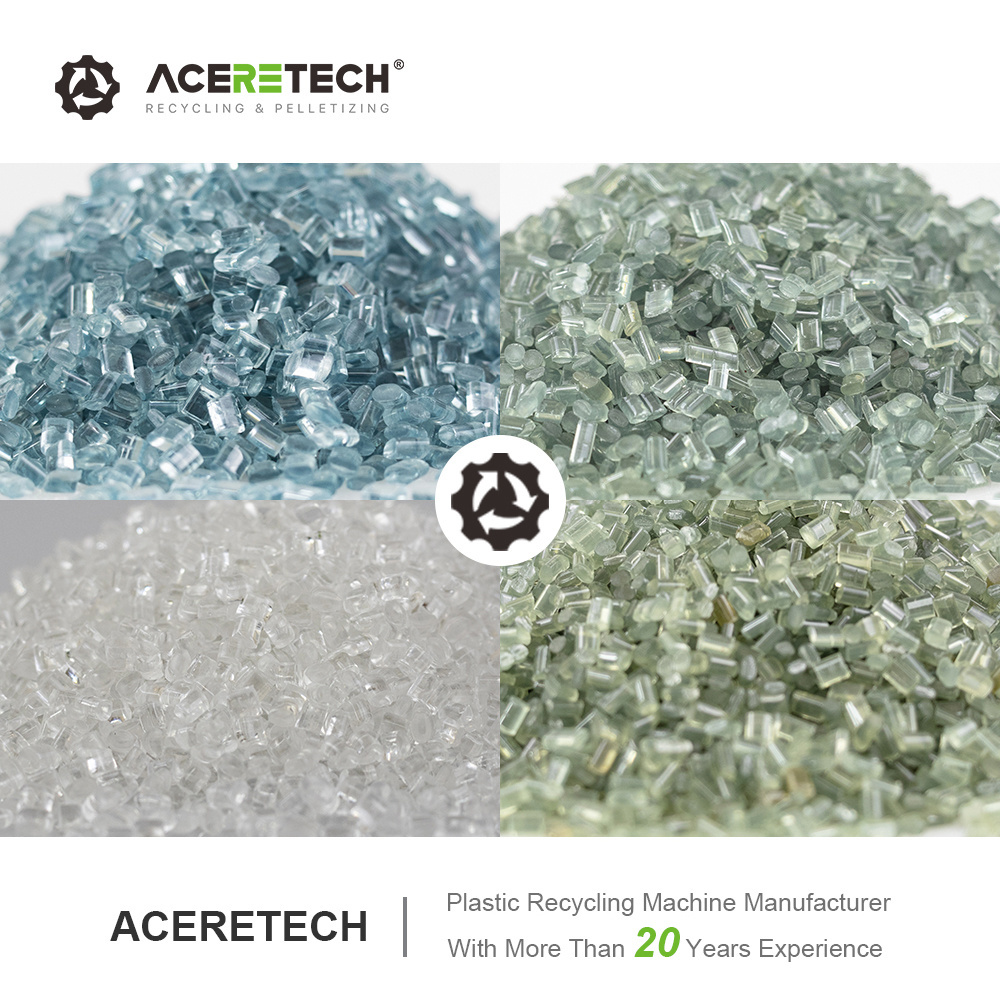

ACERETECH Recyclable Plastics Include

● LLDPE/LDPE/HDPE/PE/EPE film, crushed material, lithium battery film, foamed pearl cotton

● PP/OPP/BOPP/CPP film, woven bag,non-woven fabric (melt blown)

● PA66 fishing net, silk, factory trim, carpet

● PET/BOPET bottle flakes, film, silk, waste cloth, foam,optical film

● PTT wire

● EPS/XPS crushed material, cold briquetting foam, hot melt foam, insulation board

● HIPS/PC/ABS home appliance housing, electronic waste, factory plastic

● PVB crushed material, flakes

● PU

Suitable Products

Final Products

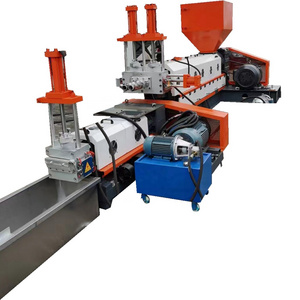

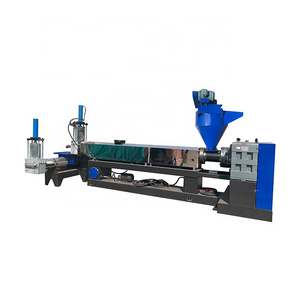

Product Paramenters

|

SPECIFICATIONS

|

|

|

|

Machine Model

|

ACS-Pro

|

|

|

Target Recycled Material

|

HDPE,LDPE,PP,BOPP,CPP,OPP,PA,PC,PS,PU,ABS

|

|

|

Final Product Shape

|

Particles

|

|

|

System composition |

Belt Conveyor, Air Exhausting Device, Sliding Gate, Cutting Compactor with Inverter, Single Screw Extruder, Filtration first,

Vacuum Degassing, Pelletizer, Water Cooling Device, Dehydration Section, Conveyor Fan, Product Silo. |

|

|

Output Range

|

320kg/h-2100kg/h

|

|

|

Feeding Device

|

Belt Conveyor (Standard), Roll Hualing off device (Optional)

|

|

|

Compactor Volume

|

800L-2800L

|

|

|

Diameter of screw

|

100mm-180mm

|

|

|

Material of screw

|

Bimetal

|

|

|

L/D of screw

|

50/ 1

|

|

|

Heater of barrel

|

Ceramic heater or Far-infrared heater

|

|

|

Cooling of Barrel

|

Air cooling of fans through blowers

|

|

|

Vacuum deashing exhaust

|

Two Double-zone vacuum degassing system (Standard)

|

|

|

Pelletizing type

|

Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing

|

|

|

Voltage Standard

|

According to the Voltage of the Customer's Location

|

|

|

Optioanl device

|

Metal detector, Roll hualing off device, Masterbatch and additives feeder

|

|

|

Warranty

|

13 months from the date of bill of lading

|

|

|

Technical services

|

project design, factory construction, installation and recommendations, commissioning

|

|

|

Model

|

Screw Diameter (mm)

|

L/D

|

Productivity(kg/h) For BOPET/PET

|

Productivity(kg/h) For LDPE/LLDPE

|

|

ACS-PRO1008

|

100

|

50

|

500-600

|

400-500

|

|

ACS-PRO1414

|

140

|

50

|

900-1150

|

900-1000

|

|

ACS-PRO1616

|

160

|

50

|

1200-1600

|

1300-1500

|

|

ACS-PRO1828

|

180

|

50

|

1800-2100

|

1800-2000

|

Product Detail

Belt Conveyor

Provide transportation of plastic materials, such as film, filament, Raffia. If you want to feed the film in rolls into the compactor, our hauling roller is optional. The feeding speed is automatically adjusted by the inverter according to the fullness of the compactor.

Metal Detector

If metal is detected in the material by the metal detector, a warning will be issued and the belt conveyor will be stopped.

Compactor

The arc-shaped plate guides the material into the extruder. This compactor combines pre-heating, pre-dry and size reduction to ensure a fast and stable feeding process.

Rotating And Fixed Blade

The rotating blade and fixed blade cut the material into small flakes. The friction heating generated by the high-speed rotating blades will per-heat and shrink the flakes.

Sliding Gate With Servo Motor

Installed between compactor outlet and screw extruder inlet. Control the open size of the sliding gate to control the materials duration time in the compactor and adjust the materials feeding capacity into the extruder.

Single Screw Extruder

Unique design first stage single screw extruder gently plastics the agglomerates.

Double Vacuum Degassing System

Volatile such as micro-molecules and moisture will be removed to make sure the high quality of the granules, which is important for heavy printed film and materials with some water content.

Gearbox

The gearbox will reduce the motor speed to the screw shafts speed and distributes it to the two output shafts.Low-noise, high torque output.

Second Filter - piston Type Filter

●

Long screen lifetime, lower screen change frequency: Long filter lifetime owing to large filter areas.

●

Easy to use and none-stop type: easy and quick screen change and do not need to stop the running machine.

●

Very low operation cost.

Second Filter - Plate Type Filter

●

The Plate type filter is made in a continuous type with two filter plates. There is at least one filter working when the screen is changing.

●

Ring-shaped heater for consistent and stable heating.

Self Clean Filter

The special design filter will greatly remove the impurities that are difficult to scrape such as aluminum foil and label paper. Straight in and out flow channels are designed for customer convenience. Automatic discharge impurities.

Water Ring Pelletizing System

●

Cutting speed is automatically adjusted according to the melt pressure on the die head to make sure even granules.

●

Pneumatic knife pressure: Cutting blades are pushed and fit completely to the die pneumatically, which can avoid the non fit caused by spring ageing.

●

Easy and fast pelletizer blades changeover, without adjustment work saves time.

Under-water Pelletizing System

Highly automatic pelletizing system. It is suitable for materials with high MFI and high production capacity requirements. This system includes pelletizer, valve, conveying pipeline, dewatering vibrating screen, silo.

Dry System

Advanced dewatering vibration sieve and horizontal centrifugal present high drying performance and low energy consumption.

Packing System

●

Final qualified granules will be blowed into and storaged in our storage silo.

●

You can control the weight of each bag granules and monitor the capacity with our capacity online monitoring & quantitative weighting system.

Intelligent System

●

Intelligent control system, fewer buttons, more-friendliness

Our system can realized one button start, one button stop and emergency stop.

●

Protection System

Our advanced system can provide workers’ life safety protection, plastics Properties Protection and protection from over-heating in compactor

●

Remote control and Data transmission

Controlling and monitoring function in LAN net.

Product Images

Hot Searches