- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DEPAI

-

Weight:

-

2000 kg

-

Marketing Type:

-

HOT Product 2023

-

Product name:

-

hot foil stamping paper cardboard creasing and die cutting machine

-

After-sales Service Provided:

-

Online Video Technical Support

-

Application:

-

Industrial Paper Cutting Machine

-

Keyword:

-

Die Cutting and creasing machine

-

Machine type:

-

Manual Feeding Paper Cutting Machine

-

Automatic Grade:

-

Manual

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

25±2 times/min

-

Max. workable width:

-

750

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DEPAI

-

Weight:

-

2000 kg

-

Marketing Type:

-

HOT Product 2023

-

Product name:

-

hot foil stamping paper cardboard creasing and die cutting machine

-

After-sales Service Provided:

-

Online Video Technical Support

-

Application:

-

Industrial Paper Cutting Machine

-

Keyword:

-

Die Cutting and creasing machine

-

Machine type:

-

Manual Feeding Paper Cutting Machine

-

Automatic Grade:

-

Manual

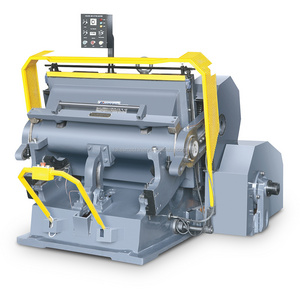

ML 750 ML930 Manual cardboard hot foil stamping paper cardboard creasing and die cutting machine

Product Overview

ML series creasing and die cutting machine, also called as clam shell die cutter, is a kind of special equipment for die cutting and creasing a wide range of material, such as paper, cardboard, plastic sheet and leather. It is applicable to the fields of printing, packaging, decoration and plastic industries. ML series machine has been well accepted by the customers from domestic and oversea market due to its outstanding performance, reliable in quality, easy for operating and low cost in price.

Features

1. Sliding bearings are made of high quality alloy copper, thus to enhance the effect of anti-frication and vibration reducing.

2. Flywheel with big moment of force and large pressure.

3. High strength due to whole iron casting by using high quality material for machine body.

4. Single plate electromagnetic clutch is sensitive and reliable

5. With functions of single piece, continuous and opening delay operating, dwell range is adjustable.

6. Operating position is reasonably designed, moving-bed can be opened to its optimum.

7. Central lubrication system guarantees fine lubrication and reduces friction.

8. Safety protection system is reliable.

9. Easy to operate.

10. Electric control system is in line with international standard.

1. Sliding bearings are made of high quality alloy copper, thus to enhance the effect of anti-frication and vibration reducing.

2. Flywheel with big moment of force and large pressure.

3. High strength due to whole iron casting by using high quality material for machine body.

4. Single plate electromagnetic clutch is sensitive and reliable

5. With functions of single piece, continuous and opening delay operating, dwell range is adjustable.

6. Operating position is reasonably designed, moving-bed can be opened to its optimum.

7. Central lubrication system guarantees fine lubrication and reduces friction.

8. Safety protection system is reliable.

9. Easy to operate.

10. Electric control system is in line with international standard.

PRODUCT SPECIFICATIONS

|

Model

|

Inner chase size

(mm)

|

Speed

(strokes/min)

|

Max.rule length(m)

|

Motor power

|

Overall dimension

(mm)

|

Machine weight

(kg)

|

|

ML750

|

750X520

|

25±2

|

≤15

|

2.2kw-6H 380V

|

1500x1320x1600

|

2000

|

|

ML930

|

930x670

|

23±3

|

≤25

|

3kw-6H 380V

|

1700x1550x1700

|

3000

|

|

ML1040

|

1040x720

|

20±3

|

≤30

|

4kw-6H 380V

|

1760X2000X1750

|

3500

|

|

ML1100

|

1100X800

|

22±2

|

≤30

|

4kw-6H 380V

|

2050x2030x1700

|

4000

|

|

ML1200

|

1200x820

|

22±2

|

≤35

|

4kw-6H 380V

|

2150x2030x1700

|

4500

|

|

ML1300

|

1300x920

|

15±2

|

≤40

|

5.5kw-6H 380V

|

2400x2100x1950

|

5600

|

|

ML1400

|

1400x1000

|

15±3

|

≤45

|

7.5kw-4H 380V

|

2450x2100x2000

|

6500

|

|

ML1500

|

1500x1050

|

14±2

|

≤45

|

7.5kw-6H 380V

|

2550x2100x2100

|

7500

|

|

ML1600

|

1600x1250

|

13±3

|

≤50

|

15kw-6H 380V

|

2700X2200X2200

|

13500

|

|

ML1800

|

1800X1280

|

13±2

|

≤60

|

15kw-6H 380V

|

2900X2200X2250

|

14200

|

|

ML2000

|

2000X1400

|

13±2

|

≤65

|

15kw-6H 380V

|

3100X2200X2250

|

15500

|

|

ML2200

|

2200X1400

|

13±2

|

≤65

|

15kw-6H 380V

|

3100X2200X2250

|

15500

|

MACHINE DETAILS

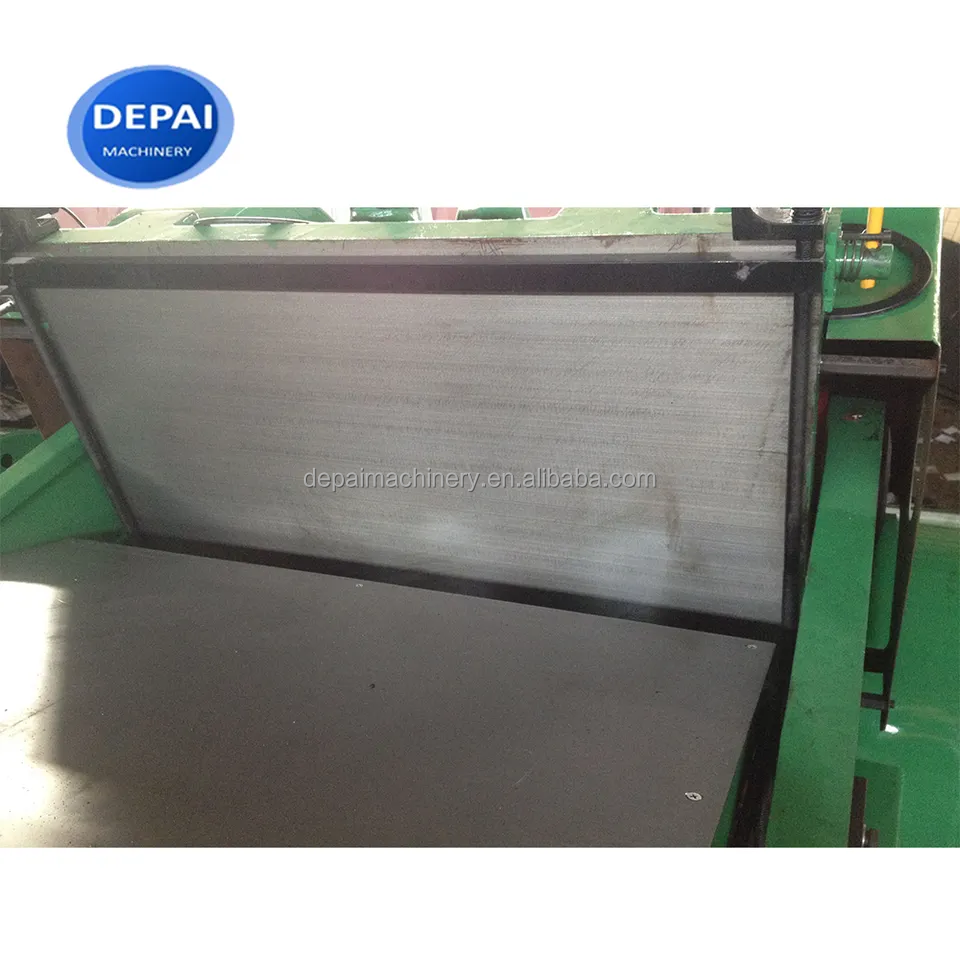

Stainless Steel Plate

Inverter

Wheel gear

Counter

Control Panel

Electric Box

Samples

Our Factory

Hangzhou Depai Machinery Co., Ltd has several production lines in different workshops from printing machines,bag making machine,label sticker die cutting & slitting machines, paper /PP/PLA straw machines,disposable products making machines ,to different plastic&paper and packaging machines.

We have a professional after-sales service team to provide you with high quality service. Engineers who can speak English can come to your factories or workshop to help you debug your machine and provide free training by video call .Our factory also cooperated with some famous French and German companies.Every year, our production director and technical director will go to the European cooperation technology companies or large factories for technical study.By communicating and learning from each other, it ensures the high quality of each machine and our technology is always far ahead in China.

We have a professional after-sales service team to provide you with high quality service. Engineers who can speak English can come to your factories or workshop to help you debug your machine and provide free training by video call .Our factory also cooperated with some famous French and German companies.Every year, our production director and technical director will go to the European cooperation technology companies or large factories for technical study.By communicating and learning from each other, it ensures the high quality of each machine and our technology is always far ahead in China.

Package

FAQ

1. Q: why should you buy from us not from other suppliers?

A: Quality and the after-sale service is our aim. We not only sell the products but solutions. We believe that you will be

satisfied with both our products and service.

2. Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very small thing (even a small screw we will choose the best quality) to the whole machine.

3. Q: What is your after-sale service?

A: Our after-sales service is first class. We have a powerful team to help you solve problems.The Warranty is one year and if the machine is damaged by natural not by human, we can send the new parts to you for free.

4. Q: What is the terms of payment you accept?

A: 30% T/T in advance, 70% T/T balance before delivery. We also accept L/C and Western Union.

A: Quality and the after-sale service is our aim. We not only sell the products but solutions. We believe that you will be

satisfied with both our products and service.

2. Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very small thing (even a small screw we will choose the best quality) to the whole machine.

3. Q: What is your after-sale service?

A: Our after-sales service is first class. We have a powerful team to help you solve problems.The Warranty is one year and if the machine is damaged by natural not by human, we can send the new parts to you for free.

4. Q: What is the terms of payment you accept?

A: 30% T/T in advance, 70% T/T balance before delivery. We also accept L/C and Western Union.

Hot Searches