- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

Crystal clear epoxy resin

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Jingu

-

Model Number:

-

204 tin can

-

Type:

-

Liquid Epoxy Resin

-

Packing specification:

-

1.6kG/group, 9 groups/carton

-

Model:

-

204 tin can

-

Color classification:

-

Light yellow

-

Glue type:

-

Super glue

-

Shelf life:

-

2 years

-

Viscosity:

-

Strong

-

Product name:

-

Epoxy AB Glue

-

Application:

-

Ceramic

-

Color:

-

Light Yellow

-

Material:

-

Epoxy Resin+hardener

Quick Details

-

CAS No.:

-

61788-97-4

-

Other Names:

-

Crystal clear epoxy resin

-

MF:

-

C6H19NO2Si3

-

EINECS No.:

-

Crystal clear epoxy resin

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Jingu

-

Model Number:

-

204 tin can

-

Type:

-

Liquid Epoxy Resin

-

Packing specification:

-

1.6kG/group, 9 groups/carton

-

Model:

-

204 tin can

-

Color classification:

-

Light yellow

-

Glue type:

-

Super glue

-

Shelf life:

-

2 years

-

Viscosity:

-

Strong

-

Product name:

-

Epoxy AB Glue

-

Application:

-

Ceramic

-

Color:

-

Light Yellow

-

Material:

-

Epoxy Resin+hardener

Product Description

|

Model:

|

204 tin can

|

|

MOQ:

|

1 piece

|

|

Customized service:

|

negotiate

|

|

Place of origin:

|

Quanzhou, Fujian, China

|

|

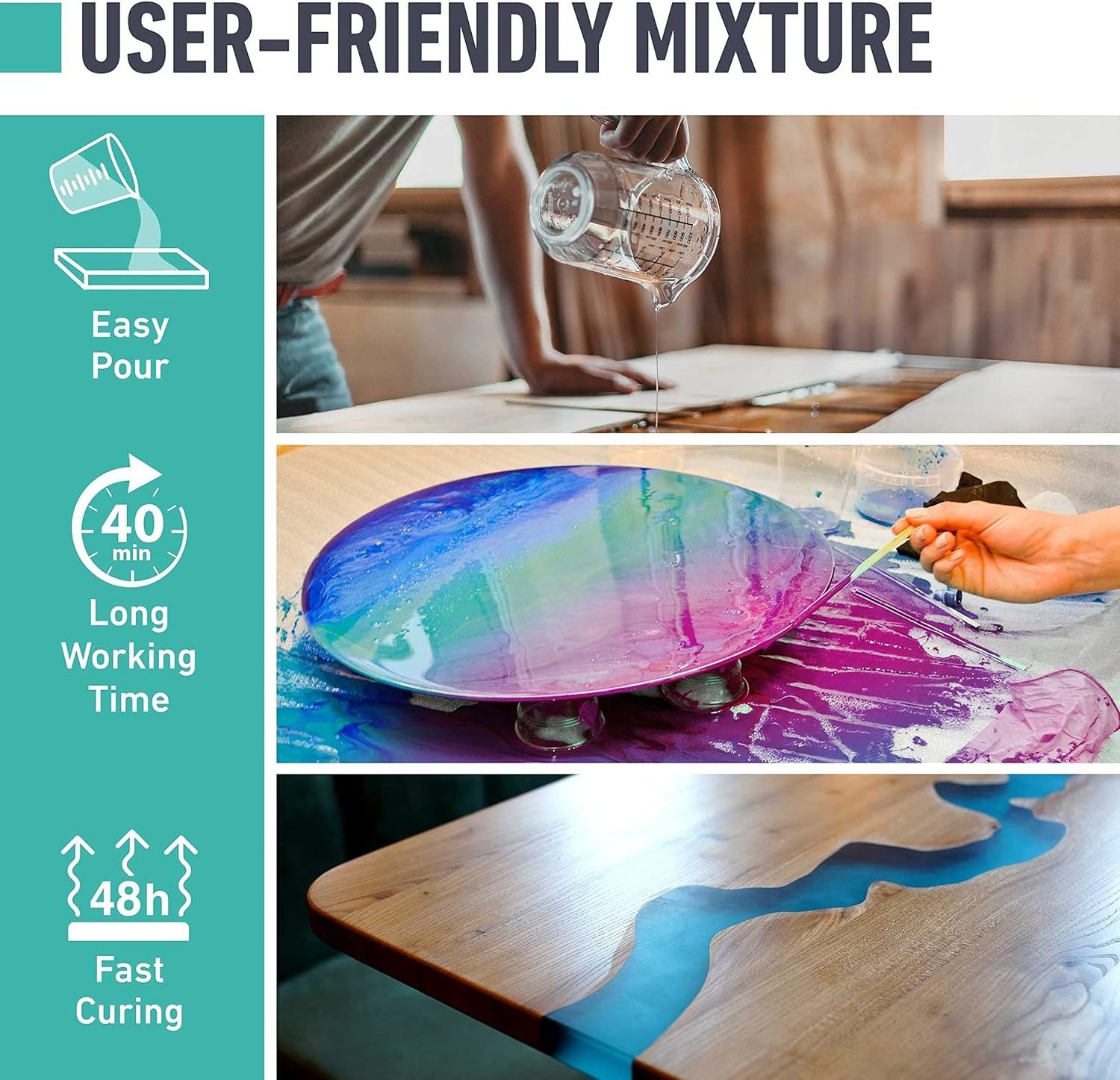

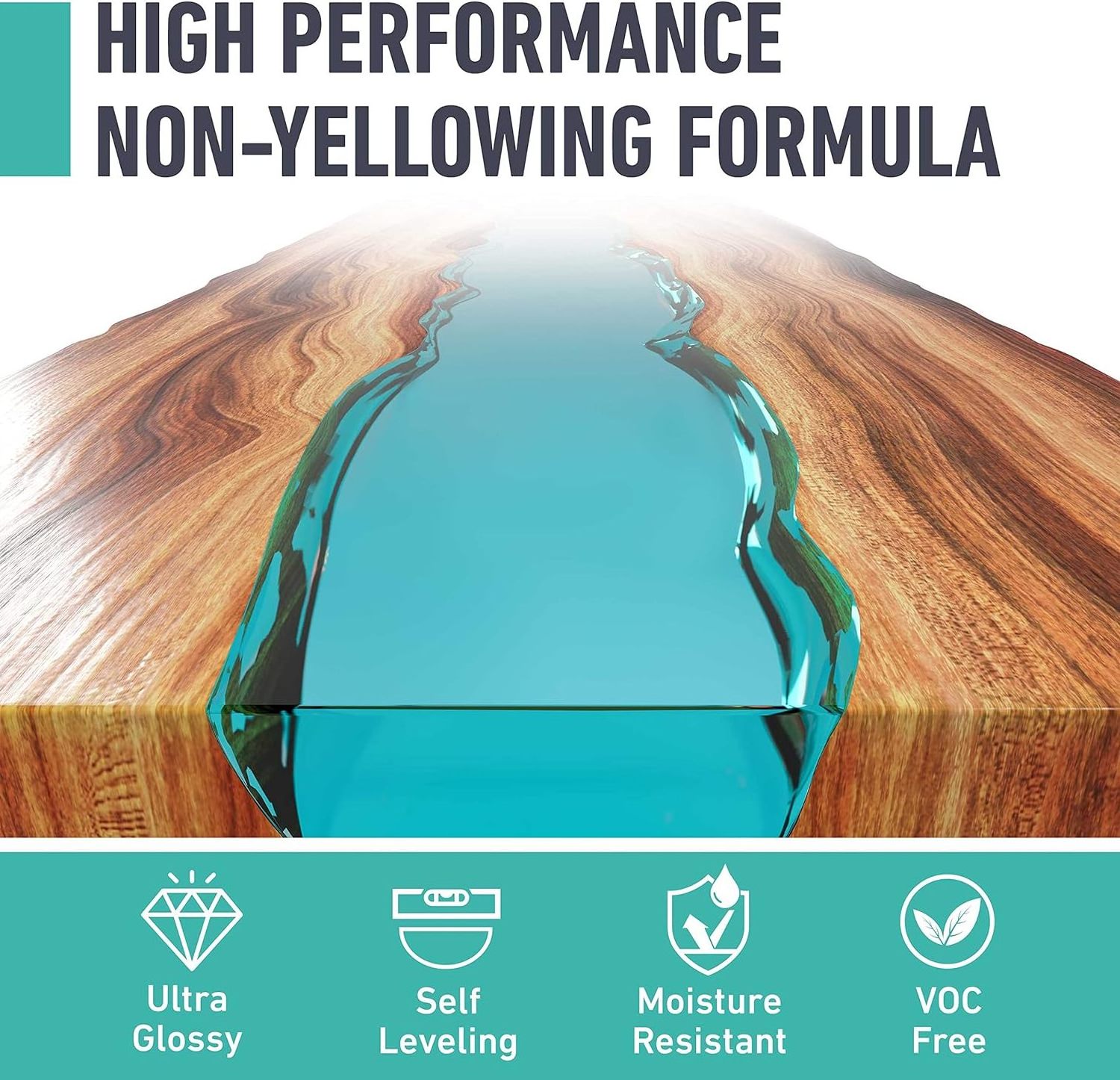

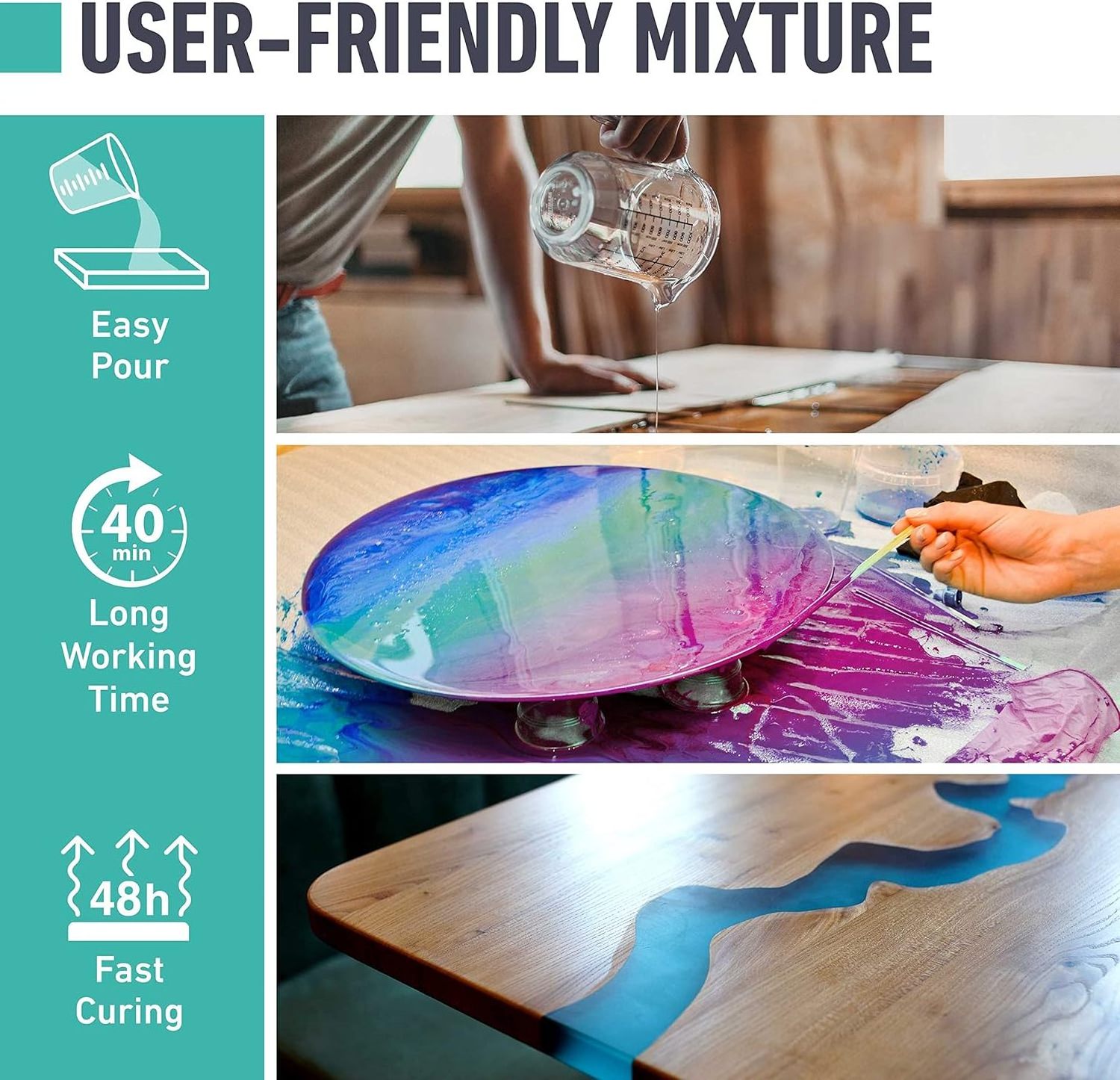

Performance characteristics:

|

low molecular weight polyamide resin is an excellent curing agent and toughening agent for epoxy resin. It has the characteristics of wide range of room temperature curing ratio and long operation period. It does not produce by-products when combined with epoxy resin, and has low shrinkage and curing. It has the advantages of non-toxicity, good toughness, good insulation performance, water resistance, wear resistance, corrosion resistance, moisture resistance and chemical stability, and has a wide range of bonding, which can be used for metal and non-metal (such as steel, iron, aluminum, ceramics Bonding of capital, glass, plastic, wood, etc.)itself and each other.

|

|

Scope of use:

|

Widely used in anti-corrosion coatings, paints, adhesives, inks, molding materials, potting materials, electrical insulation,glass fiber reinforced plastics and other industrial and civil fields such as petroleum, chemical, aerospace, automobile,

construction, etc. |

|

How to use:

|

The use ratio of 650 low molecular polyamide and epoxy resin can be changed in the range of 1: 1---1: 1.5; when the amount of polyamide resin increases, the cured product is more flexible, but resistant to The thermal medium resistance is slightly reduced,and when the dosage is reduced, the hardness of the cured product increases. Add no more than 50% of fillers (such as aluminum powder, iron powder, porcelain powder, quartz powder, mica powder, etc.) as needed. ...

|

Hot Searches