- Product Details

- {{item.text}}

Quick Details

-

Name:

-

Steel Spur Pinion Gear

-

Pressure Angle:

-

20°, 14.5°

-

Size:

-

Customer's Drawing

-

Service:

-

OEM ODM

-

Tooth Profile:

-

Involute

-

Application:

-

Industry

-

Quality:

-

Tolerance Required

-

Type:

-

Power Transmission Parts

-

Module:

-

M0.3-M6

-

Processing:

-

Hobbing Teeth

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LS

-

Name:

-

Steel Spur Pinion Gear

-

Pressure Angle:

-

20°, 14.5°

-

Size:

-

Customer's Drawing

-

Service:

-

OEM ODM

-

Tooth Profile:

-

Involute

-

Application:

-

Industry

-

Quality:

-

Tolerance Required

-

Type:

-

Power Transmission Parts

-

Module:

-

M0.3-M6

-

Processing:

-

Hobbing Teeth

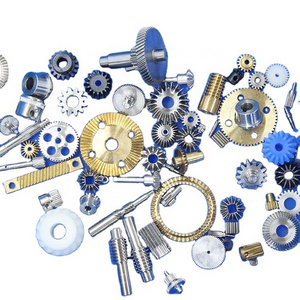

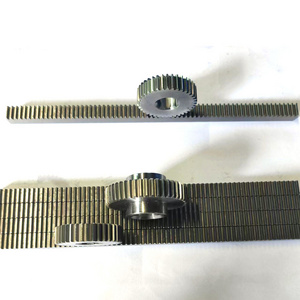

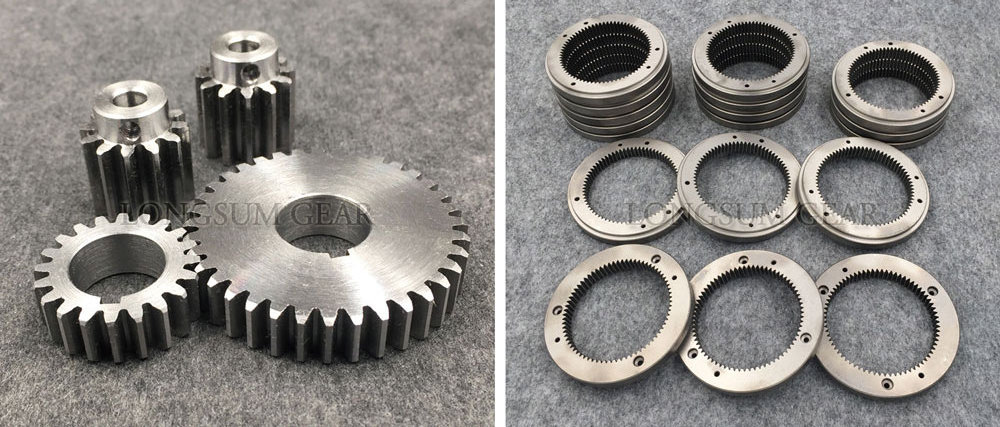

Steel Spur Pinion Gear

Spur gears are widely accepted as the most efficient type of gearing solution, when the application of transmitting power and uniform rotary motion from one parallel shaft to another is required. Determined by the center distance, spur gears create a steady functioning speed drive. This drive speed can be decreased or increased by the variable number of teeth that exist in the driving gear.

Several of our custom spur gears have been used in gear train applications - where multiple gears are required to have the same pressure angle and diameter pitch. They are available in plastic, non-metallic, brass, steel and cast iron. In addition ,these parts are manufactured many style types: plain, web, web with lightening holes, and web with spokes. Many are available with or without hubs.

| Gear Types |

spur gear, helical gear, internal spur gear, ring gear, straight/spiral bevel gear, hypoid gear, crown wheel & pinion, gear shaft, worm gear & worm shaft, spline shaft & bushing, etc. |

| Gear Material |

Steel: C45, 40Cr <AISI/SAE 5140>, 42CrMo <AISI 4140/4142>, 20CrMnTi, 20CrNiMo <AISI/SAE 8620>, ect. Aluminum Alloy: 2024, 7075, etc. <we advise these instead of 6061/6063> Brass, Bronze, Aluminum Bronze, etc. POM Plastic, MC901 Nylon, etc. |

| Processing |

blank turning tooth h obbing, broaching, m illing, s haping, etc. bore honing tooth shaving, tooth grinding |

| Heat Treating |

tooth induction quenching, vacuum quenching, etc. for 45-50HRC; carburizing for 56-62 HRC; nitriding, carbon-nitriding for gears required abrision resistant; |

| Application | Automotive, Agricultural, Electronic, Industrial, Medical, Defense, Off-highway, ect. |

All gears are packaged for safe shipping and convenient storage. Gears are carefully packaged using the most appropriate materials and method for the gear type.

We'd like to work with your forwarder to ship the products to you. We also work with experienced forwarders to shipping the products to client all over the world. I f you don't have any forwarder to do the shipping, please let us know the most convenient port for you, then we can arrange the shipment for you.