It happens when your seawalls are constructed with materials that are not as durable and will fail significantly.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

606mm

-

Thickness:

-

9mm 10mm 11mm, 9mm 10mm

-

Size:

-

606mm

-

Product name:

-

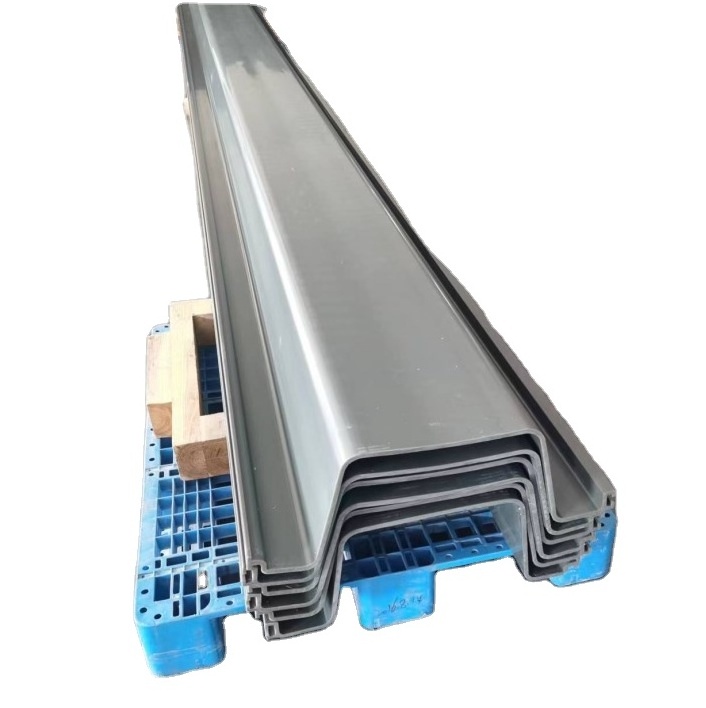

Vinyl seawall piling

-

Section width:

-

606mm

-

Section depth:

-

130mm

-

Color:

-

Grey/customized

-

Standard:

-

ASTM

-

Working life:

-

50 years

-

Alloy or not:

-

No alloy

-

Using feature:

-

Anti-rot or anti-rust

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Long Zhuo

-

Model Number:

-

606mm

-

Thickness:

-

9mm 10mm 11mm, 9mm 10mm

-

Size:

-

606mm

-

Product name:

-

Vinyl seawall piling

-

Section width:

-

606mm

-

Section depth:

-

130mm

-

Color:

-

Grey/customized

-

Standard:

-

ASTM

-

Working life:

-

50 years

-

Alloy or not:

-

No alloy

-

Using feature:

-

Anti-rot or anti-rust

Product Description

When would we use the sheet piling?

When you do embankment works, marine structure restore projects or sea/river bank protection projects, you may think of sheet piles.

Have you ever seen this?

Occasionally, you may think wooden sheet pile is a good choice, but soon failed.

It is well known that wood fades over time. Paint may cover that up, but the paint color will fade as well. There is really not a lot you can do except continue to paint in order to keep it looking nice.

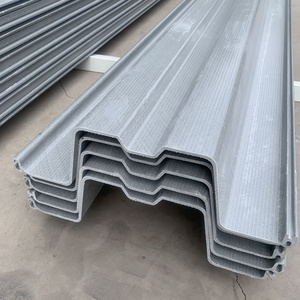

Vinyl PVC sheet pile is the most wise choice!

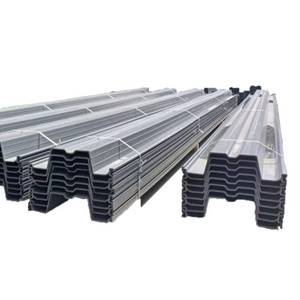

Vinyl sheet piles are an environmentally friendly, lightweight, extremely durable and costs efficient alternative to the traditional materials such as steel, concrete or wood. They are used in construction projects more and more broadly because of their excellent parameters and the possibility of lowering investment costs.

Product specification

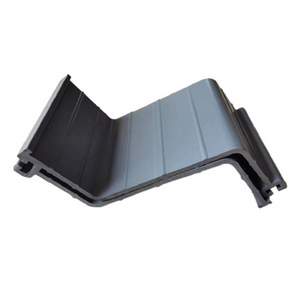

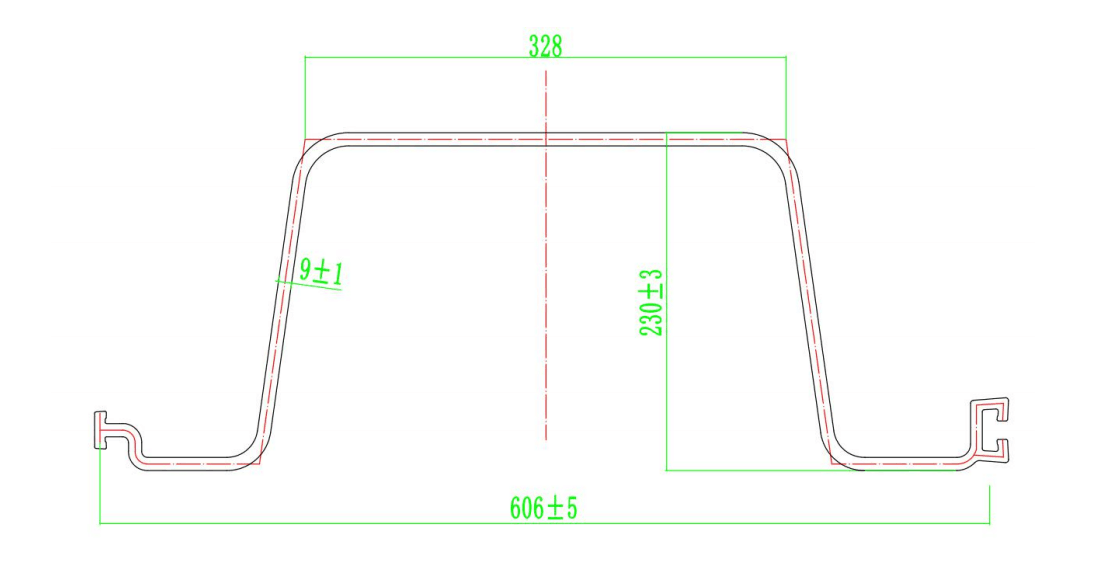

U type PVC sheet piling technical drawing

|

Section width

|

606mm

|

|

|

|

|||

|

Section depth

|

230mm

|

|

|

|

|||

|

Thickness

|

9mm/ 10mm

|

|

|

|

|||

Z type PVC sheet piling technical drawing

|

Section width

|

457mm

|

|

|

|

|||

|

Section depth

|

254mm

|

|

|

|

|||

|

Thickness

|

9mm/10mm/11.18mm

|

|

|

|

|||

Product features

Why use PVC sheet piling?

Product Applications

Taking into account their complete resistance to biological and atmospheric factors, as well as mechanical damage, PVC sheet piling may be used in a wide range of civil engineering projects. The EcoLock sheet piling used in place of steel retaining walls reduces the costs of installation and materials. As an alternative to wooden solutions, EcoLock ensures higher durability and resistance to external factors.

Used to protect places with variable or raised groundwater level, PVC sheet piling efficiently reduces water infiltration as well as secures the terrain against gradual erosion and degradation.Groundwater cut-off Chemical containment, Fluid Seepage Barriers, Protection of Foundation Structures.

Water control system

River bank protection and regulation

Baffle Walls for water or waste water flow control

• River Weirs

• Pond Linings

• Channel Linings for agricultural applications

• River Diversion

• Mining drainage systems

Marine structures

The marine applications include:

• Marine Bulkheads & Seawalls

• Tide Walls

• Breakwaters

• Wave Breaks

• Jetty Structures

• Groins

• Scour Protection and Erosion Control

• Retaining Walls

Erosion control system

--

beachfront protection

--coastline protection

--road protection

--bulkheads construction

Successful projects:

Project in Philippines

Project in Poland

Project in Indonesia

Project in Australia

Installation

The most commonly used method, in which sheet piles are mechanically embedded into the soil along the pre-installed templates with

the use of vibratory hammers, i.e. light equipment with small impact energy.

■ hammering sheet piles in very difficult soil

environments (compact silt, clay, gravel)

environments (compact silt, clay, gravel)

■ installation of long profiles, even up to 12m ■ removing obstacles found in soil

(roots, stones)

(roots, stones)

■ maintaining straight lines

■ ensuring pre-loosening of soil

■ significant acceleration of installation work

Jetting

This method is used in cases of very compact or cohesive soil where the force of vibration hammers is not sufficient to embed the vinyl sheet piling to the required depth. Jetting consists in exerting pressure directly under the sheet piles which are being installed, which helps loosen and remove the soil or the obstacles.

Special water or air ejectors are used in this technology.

Packing & Delivery

Hot Searches