- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

EMA

-

Product name:

-

ema

-

Material:

-

Plastic Raw Material Granule

-

Color:

-

Customer Requirement

-

Keyword:

-

Ethylene Methy Acrylate Copolymer Resin

-

Appearance:

-

Transparent Granule

-

Usage:

-

Injection Molding Products

Quick Details

-

color:

-

NATURE

-

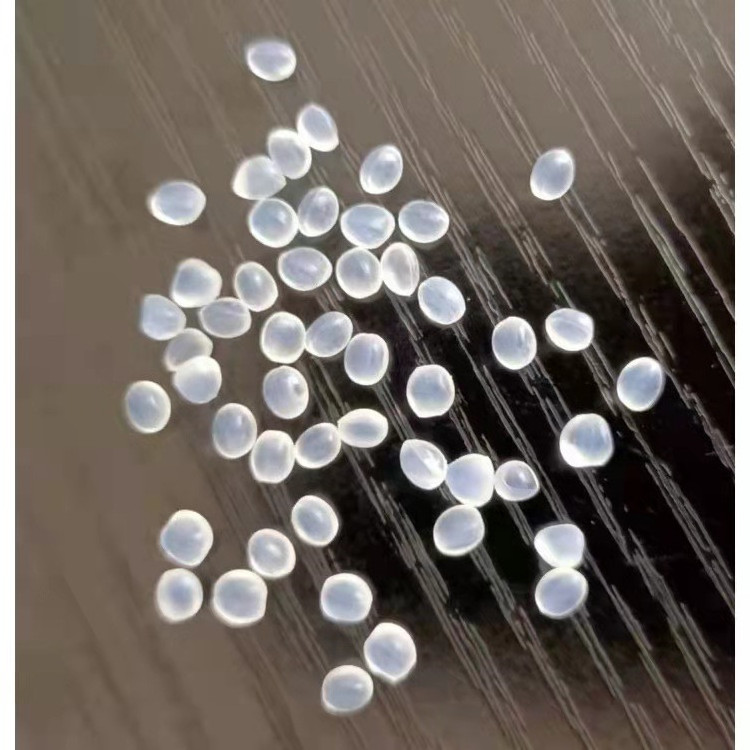

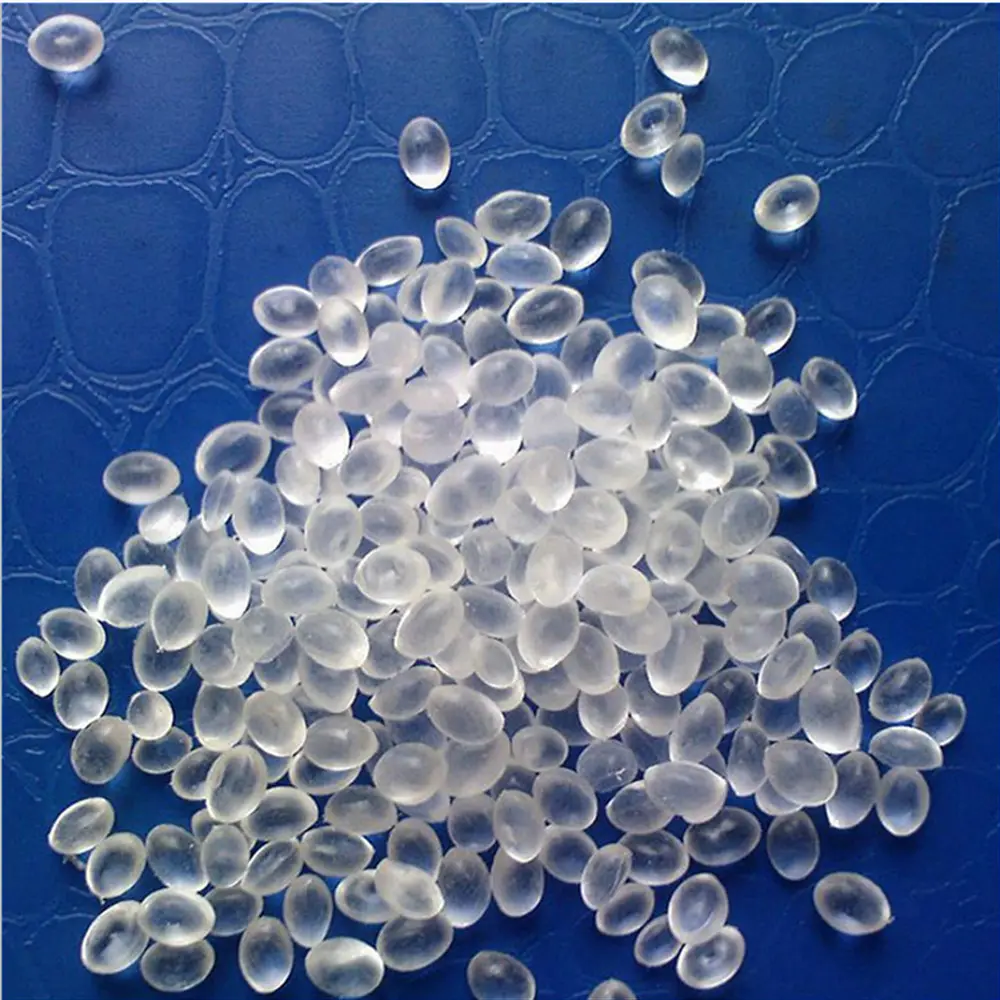

Shape:

-

PELLET, Custom Shape

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

EMA

-

Product name:

-

ema

-

Material:

-

Plastic Raw Material Granule

-

Color:

-

Customer Requirement

-

Keyword:

-

Ethylene Methy Acrylate Copolymer Resin

-

Appearance:

-

Transparent Granule

-

Usage:

-

Injection Molding Products

Chemical Name : Ethylene-Methyl Acrylate Copolymer From ethylene and methyl acrylate as raw materials, oxygen or peroxide as initiator, high pressure heating polymerization. Can be blown into film for disposable gloves, medicine and food packaging; Extruded hoses and profiles; Blow molding toys; Foaming foam sheet, etc.Ethylene - methyl-acrylate copolymer (EMAC) : It is the most thermally stable of all high pressure α-olefin copolymers. Whether as a single material or admixture, EMAC is used in films, extruded adhesives, and sheets. There are many applications in molding,blow molding, pipe extrusion and co-extrusion.It can be filled with more than 50% filler without affecting its elasticity, and is compatible with all polyolefin resins, so it

can be used as a matrix resin for master materials. The film has a softness similar to latex rubber and is suitable for disposable gloves and certain medical supplies.

Application

1. Packaging material

As an extrusion coating resin, EMA has good adhesion with PE, PP, PA, PVDC and other substrates, providing an excellent balance

between the co-extruded interlayers of LDPE and EVA and the adhesion of the substrate surface. It is widely used in food packaging

such as sour milk cup lid, convenient noodle bowl lid and other easy to tear film and multi-layer co-extruded packaging.

2. Medical and sanitary products

As a blowing film resin, it is widely used in the production of soft elastic film, low melting point packaging bags, disposable

gloves, medical disinfection covers and so on.

3. Polymer modification

It can be used as a room temperature toughening agent for ABS, PA, PC, PBT, PET, PBT/PC, PC/ABS, PP and other polymers

4.. Car soundproofing material

Can be used to produce foaming materials, with uniform foaming, soft, high temperature resistance and other characteristics, can

also be cross-linked; The foaming properties of PE and PP can be improved by blending with PE and PP.

1. who are we?

We are based in Hebei, China, start from 2020,sell to North America(30.00%),South America(20.00%),Western Europe(15.00%),Southeast Asia(15.00%),Southern Europe(10.00%),Northern Europe(10.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

organic intermediate,daily chemicals,EVOH,PP,Plastic particles

4. why should you buy from us not from other suppliers?

null

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian