- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

580 KG

-

Product Name:

-

500L 1000L 2000L Beer Brewing Equipment

-

Application:

-

Brewpub Beer Brewery Restaurant

-

Material:

-

SUS304/SUS316/red Copper

-

Capacity:

-

500L, 1000L, 2000L

-

Heating way:

-

Steam Electric Heating Beer Brewing Equipment

-

Usage:

-

DIY Beer

-

Application Industrie:

-

Beer

-

Heat Insulation:

-

Polyurethane-thickness: 80mm

-

Inner jacket thickness:

-

3mm

-

Outer jacket thickess:

-

2mm

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Rain Star

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

580 KG

-

Product Name:

-

500L 1000L 2000L Beer Brewing Equipment

-

Application:

-

Brewpub Beer Brewery Restaurant

-

Material:

-

SUS304/SUS316/red Copper

-

Capacity:

-

500L, 1000L, 2000L

-

Heating way:

-

Steam Electric Heating Beer Brewing Equipment

-

Usage:

-

DIY Beer

-

Application Industrie:

-

Beer

-

Heat Insulation:

-

Polyurethane-thickness: 80mm

-

Inner jacket thickness:

-

3mm

-

Outer jacket thickess:

-

2mm

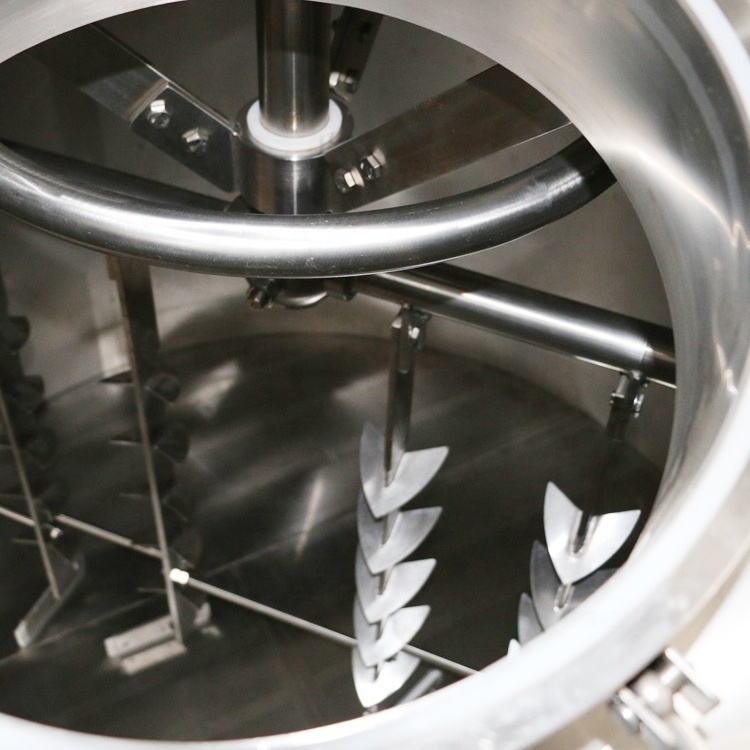

500L brewery Equipment

Micro Brewing Machine Turnkey Project

500L brewery equipment is widely used in brewery factory, restaurant, bars, hotels and so on. It can brew pale lager, amber lager, dark lager, ale etc at proper temperature with different raw material. Rain Star can produce stainless steel 304 brewhouse, copper and etc according to the customers' requirement.

Stainless Steel Fermentation

Specifications of 500L brewery Equipment

Micro Brewing Machine Turnkey Project

|

Model

|

RS-BE

|

||||||

|

Capacity

|

500L/Batch (or 1000L/Batch, 1500L/Batch)

|

||||||

|

Material

|

SUS304 food grade

|

||||||

|

Application

|

Restaurants, bars, hotels, brewery, Laboratory

|

||||||

|

Heating way

|

Steam heating/ Electric heating/ Direct Fire heating

|

||||||

|

Voltage

|

AC380/220V,50/60HZ

|

||||||

|

Power

|

27Kw

|

||||||

|

Water consumption

|

3.5m3/T

|

||||||

|

Diameter

|

1160mm

|

||||||

|

Height

|

2800m

|

||||||

|

Degree of automation

|

Semi-automatic/Fully automatic

|

||||||

2 Vessels Main Features:

A typical two-vessel Combination Mash Lauter Tuns are the first combination vessel in these brewhouses line ups. Next inline is the combination of the Kettle and Whirlpool tanks.

3 Vessels Main Features:

A three vessels brewhouse is hybrid system that incorporates at least one combination vessel and two dedicated process vessels.

4 Vessels Main Features:

A typical four vessels brewhouse will include a Mash tun, Lauter Tun, Kettle tun and Whirlpool tun. Each of these tanks is dedicated to performing a single process, and is designed differently than similar vessel used for performing multiple processes.

Advantages of our brewery equipment:

1. Good cost performance.

2. Good abrasion resistance materialcopper beer equipment.

3. We all adopt SUS304 to produce our equipment. The thickness of inner jacket and seal head of the tanks are all 3.0mm. The thickness of external jacket

is 2.0mm. It ensure the good pressure resistance and good abrasion resistance.

4. Polishing accuracy up to Ra0.4μ m.

5. Strict tank pressure test.

6. Energy conservation and pollution emissions.

2. Good abrasion resistance materialcopper beer equipment.

3. We all adopt SUS304 to produce our equipment. The thickness of inner jacket and seal head of the tanks are all 3.0mm. The thickness of external jacket

is 2.0mm. It ensure the good pressure resistance and good abrasion resistance.

4. Polishing accuracy up to Ra0.4μ m.

5. Strict tank pressure test.

6. Energy conservation and pollution emissions.

|

Model

|

Production capacity

|

Volume in US Gallon

|

Heating area

|

Tank diameter

|

Height

|

|

RS-BT100

|

100L/day

|

26US Gallon

|

0.25m2

|

650mm

|

2000mm

|

|

RS-BT200

|

200L/day

|

53US Gallon

|

0.25m2

|

850mm

|

2200mm

|

|

RS-BT300

|

300L/day

|

79US Gallon

|

0.3m2

|

950mm

|

2500mm

|

|

RS-BT500

|

500L/day

|

132US Gallon

|

0.5m2

|

1160mm

|

2800mm

|

|

HG-1000

|

1000L/day

|

264US Gallon

|

1.0m2

|

1360mm

|

3000mm

|

|

HG-2000

|

2000L/day

|

528US Gallon

|

2.0m2

|

1760mm

|

3150mm

|

|

HG-3000

|

3000L/day

|

792US Gallon

|

3.0m2

|

1860mm

|

3800mm

|

|

HG-5000

|

5000L/day

|

1320US Gallon

|

5.0m2

|

2260mm

|

4400mm

|

FAQ

Q: How many years of experience in brewing equipment do you have?

A: We have more than 10 years in brewing and beer filling equipment.

Q: Where is your factory located?

A: Our factory is located in Ningbo city, Zhejiang province of China, welcome to visit our factory at any time.

Q: How could we confirm the details of the products?

A: We will provide all the drawings for you to confirm before production.

Q: Do you have any sales reference?

A: We exported our products to many countries, such as the United States, Canada, South Africa, Japan, Korea, Argentina, Netherland, Germany, Iceland and Armenia etc.

A: We have more than 10 years in brewing and beer filling equipment.

Q: Where is your factory located?

A: Our factory is located in Ningbo city, Zhejiang province of China, welcome to visit our factory at any time.

Q: How long the warranty will be?

A: 3 years warranty for the whole tank and the main equipment, 1 year for the accessories and auxiliaries.

A: 3 years warranty for the whole tank and the main equipment, 1 year for the accessories and auxiliaries.

Q: How could we confirm the details of the products?

A: We will provide all the drawings for you to confirm before production.

Q: Do you have any sales reference?

A: We exported our products to many countries, such as the United States, Canada, South Africa, Japan, Korea, Argentina, Netherland, Germany, Iceland and Armenia etc.

Q: How about the installation?

1.Pre-service :

- Layout: Sent us your building floor plan, or the sketch, or tell us the size (length, width, height), we will offer you an equipment footprint according to your requirement.

- Technical Drawings : We will offer Technical Drawings of each tank based on the equipment layout .

- 3D effective sketch: We will 3D effective sketch to make sure ensure you have a more intuitive experience

Hot Searches