- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customization

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

customization

-

Fish feed machine Processing Types:

-

Twin screw extrusion system

-

Fish feed machine material:

-

stainless steel food grade

-

Fish feed machine function:

-

Full automatic and multi - function

-

Fish feed machine Capacity:

-

100-2000 kg per hour

-

Fish feed machine Application:

-

floating or sinking fish feed , dog food and so on

-

Fish feed machine Inverter:

-

LG DELTA SIMENSE ABB(or Customized)

-

Fish feed machine Screw Material:

-

Alloy Steel (38CrMoAl)

-

Fish feed machine Heating method:

-

Electric Heating

-

Fish feed machine Motor brand:

-

Siemens China Beide or custom

-

Fish feed machine Feature:

-

wide range choice for machine size

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XILANG

-

Voltage:

-

customization

-

Power:

-

customization

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

customization

-

Fish feed machine Processing Types:

-

Twin screw extrusion system

-

Fish feed machine material:

-

stainless steel food grade

-

Fish feed machine function:

-

Full automatic and multi - function

-

Fish feed machine Capacity:

-

100-2000 kg per hour

-

Fish feed machine Application:

-

floating or sinking fish feed , dog food and so on

-

Fish feed machine Inverter:

-

LG DELTA SIMENSE ABB(or Customized)

-

Fish feed machine Screw Material:

-

Alloy Steel (38CrMoAl)

-

Fish feed machine Heating method:

-

Electric Heating

-

Fish feed machine Motor brand:

-

Siemens China Beide or custom

-

Fish feed machine Feature:

-

wide range choice for machine size

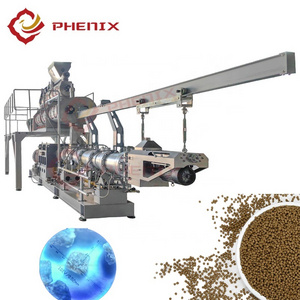

Small Capacity 50-80kg/h Electric Floating Fish Feed Pelletizer Machine Mill Pellet Food Extruder Machine For Trout Fish

Products Description

1.Main Introduction for

floting fish feed making machines

fish feed machine floating

can be Widely used in the production of fish and shrimp , crabs , abalone , sea cucumbers and various ornamental fish feeds. It is and ideal choice for manufactures with rigid requirements. The whole machine is made of stainless steel which can ensure hygiene and cleanliness. The technology uses internationally advanced twin screw extrusion technology.

2.

fish feed machine floating

normally works in production line type, the flow chart of whole

fish feed machine floating

production line:

Mixer - Screw Conveyor - Twin screw extruder - Automatic Dryer - Cooling Machine

diesel engine fish feed pellets machines floating fish feed pellet machine trade catfish feed pellet making machine

PRODUCT SPECIFICATIONS

1.Technical Parameter of floting fish feed making machines

Here is main introduction for the

fish feed machine floating

technical parameter, welcome to contact with us for detail information.

|

Model

|

XL65

fish feed line

|

XL70

fish feed line

|

XL85

fish feed line

|

XL90

fish feed line |

|

Main Power

|

22kw

|

30kw

|

45kw

|

110kw

|

|

Drying Method

|

Electric or Steam

|

Electric or Steam

|

Electric or Steam

|

Electric or Steam

|

|

Capacity

|

120-150 kg/h

|

150-180 kg/h

|

300-400 kg/h

|

1000-1200 kg/h

|

2.

fish feed machine floating

Voltage

Three phases: 380 V/50 Hz, Single phase: 220 V / 50 Hz. we can make it according to customers' Local voltage according to different countries.

3.

fish feed machine floating

Raw material

fish feed machine floating

Adopts corn powder,rice powder,wheat flour,meat as raw materials meanwhile mixing with water and oil.The material could also be according to custom real situation,but need to be tested by

fish feed machine floating

4. Fish feed samples produced by the

floting fish feed making machines

5.

fish feed machine floating

details :

1.

floting fish feed making machines

1.1.The main extruder of

fish feed machine floating

adopts frequency speed with high automation

controlling

.

1.2.The screws of fish feed machine floating are made of the special alloy steel which has the advantage of durable usage, high pressure,and longer life.

1.3.The forced lubrication system of fish feed machine floating can guarantee the equipment transmission life longer.

1.4.Auto-temperature control system and self-cleaning of fish feed machine floating makes it more convenient.

1.5 fish feed machine floating has the widest range of applications and can produce different products with different equipment and models.

1.2.The screws of fish feed machine floating are made of the special alloy steel which has the advantage of durable usage, high pressure,and longer life.

1.3.The forced lubrication system of fish feed machine floating can guarantee the equipment transmission life longer.

1.4.Auto-temperature control system and self-cleaning of fish feed machine floating makes it more convenient.

1.5 fish feed machine floating has the widest range of applications and can produce different products with different equipment and models.

2. Dryer which will work with the

floting fish feed making machines

2.1. Various types of dryers can be offered which like fuel ovens, gas ovens, electric ovens, and high temperature inflated ovens, microwave dryer.

2.2.Dryer is compact, has small dry area and a large superficial area. It also features small scale of heat elimination and high thermal efficiency.

2.3.Mesh belt conveyors and thermal insulation boards all use stainless steel material, making the equipment clean and sanitary.

2.4. The speed of mesh belt conveyor is adjustable, the drying period for food in the oven can be adjusted.

2.5. The automatic temperature control system makes it possible to set the temperature according to your needs.

2.2.Dryer is compact, has small dry area and a large superficial area. It also features small scale of heat elimination and high thermal efficiency.

2.3.Mesh belt conveyors and thermal insulation boards all use stainless steel material, making the equipment clean and sanitary.

2.4. The speed of mesh belt conveyor is adjustable, the drying period for food in the oven can be adjusted.

2.5. The automatic temperature control system makes it possible to set the temperature according to your needs.

Product Category

SALES AND SERVICE NETWORK

Hot Searches