- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Minx, MINX

-

Model Number:

-

Minx-01, MINX002

-

Surface Treatment:

-

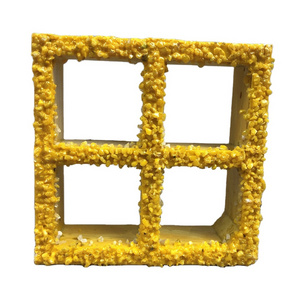

Concave,gritted,smooth, Concave,gritted,smooth

-

Product name:

-

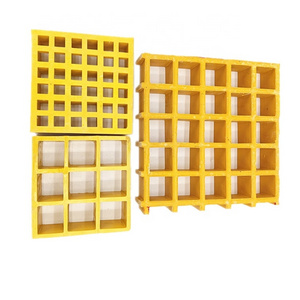

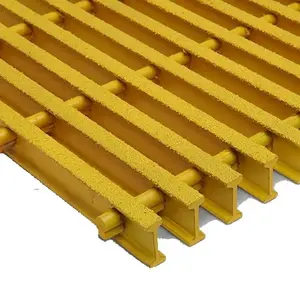

Fiberglass Pultruded Grating

-

Color:

-

Customized Colors

-

Material:

-

Resin fiberglass composite

-

Fiberglass content:

-

24% - 30%

-

Thickness:

-

Customized Thickness

Quick Details

-

Application:

-

Flooring walkway/drainage/chemcial plant/driveway

-

Technique:

-

Pultrusion

-

Place of Origin:

-

Hebei, China, Hebei, China

-

Brand Name:

-

Minx, MINX

-

Model Number:

-

Minx-01, MINX002

-

Surface Treatment:

-

Concave,gritted,smooth, Concave,gritted,smooth

-

Product name:

-

Fiberglass Pultruded Grating

-

Color:

-

Customized Colors

-

Material:

-

Resin fiberglass composite

-

Fiberglass content:

-

24% - 30%

-

Thickness:

-

Customized Thickness

Products Description

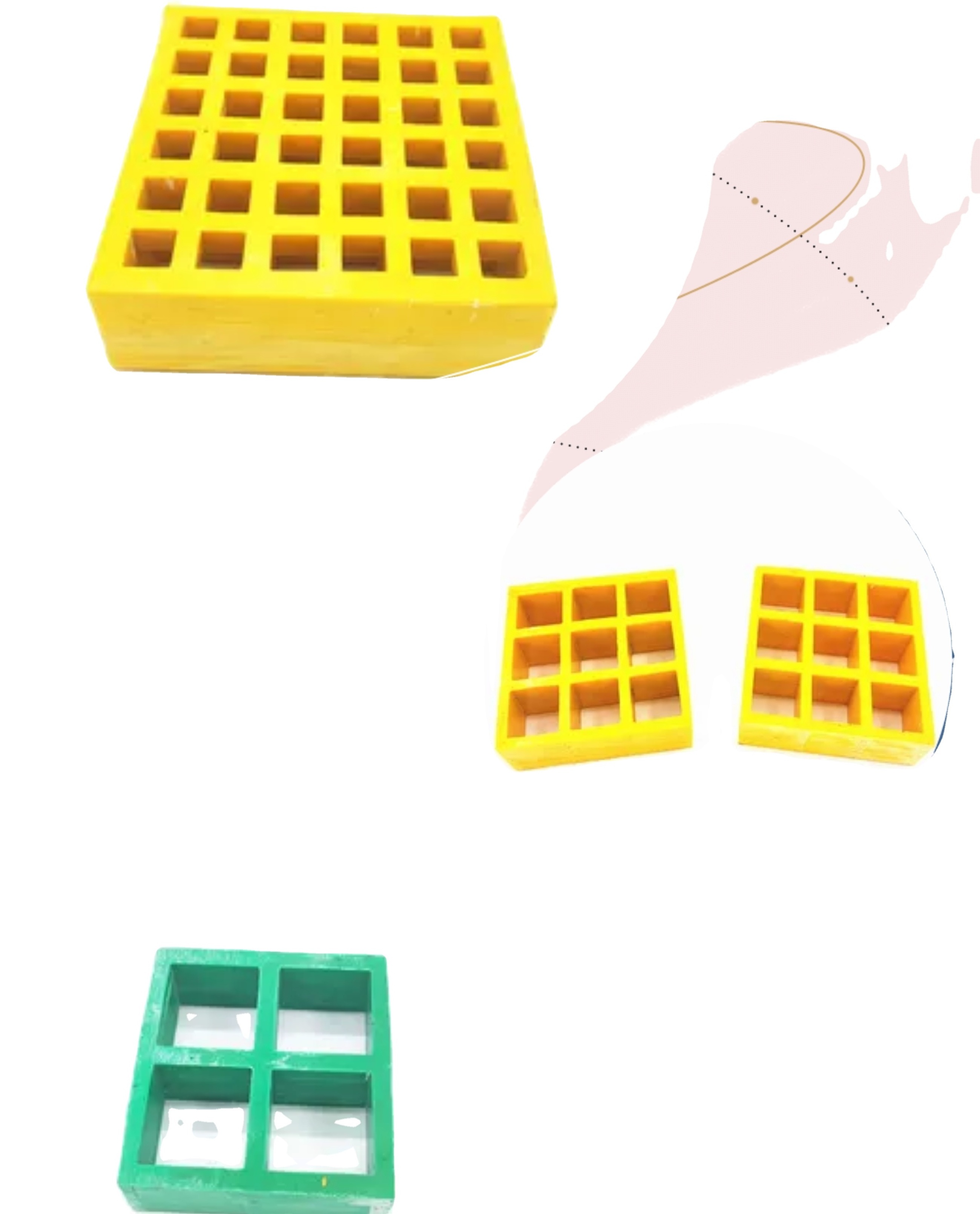

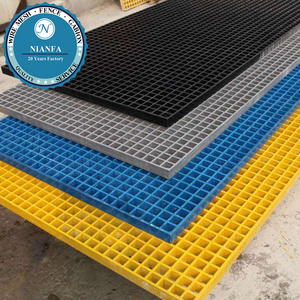

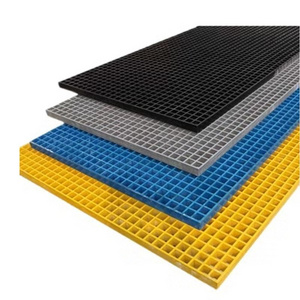

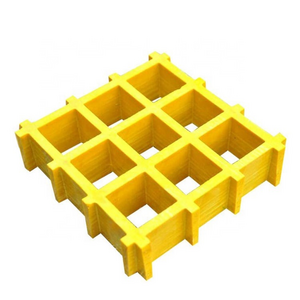

Frp Walkway GratingFiberglass Walkway GratingFiberglass Deck Grating

|

Properties

|

Corrosion Resistant, Slip Resistant

|

|

|

High Strength to Weight Ratio, High Load Capacity

|

|

|

Long Service Life ,Bi -directional Strength (Equally Strong in Both)

|

|

|

Lightweight , an Alternative to Steel Grating

|

Details Images

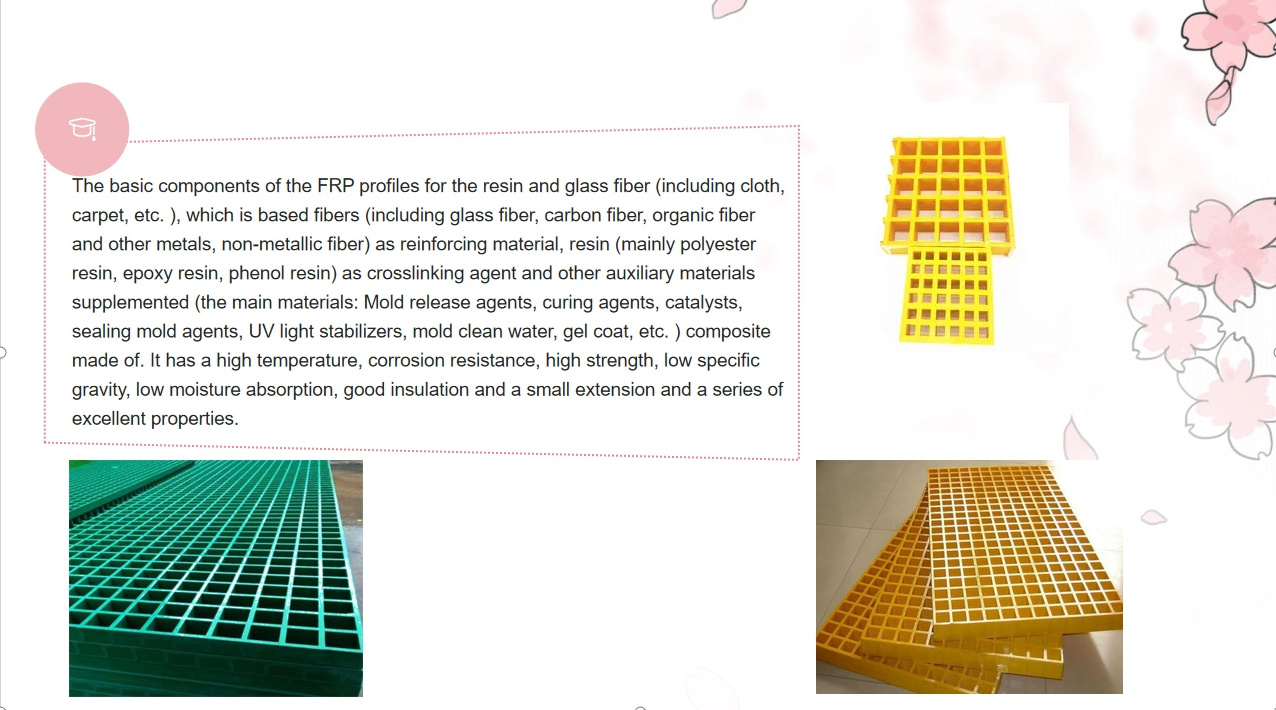

Material

Production steps

1. Stirring raw materials

Resin, fiberglass fiber yarn, calcium powder filling, color paste, reagents, etc. are arranged in proportion, stirring for 20

minutes.

minutes.

2. Pouring material

Pouring the mixed raw materials onto the mold machine corresponding to the FRP grating.

3. Draw yarn

Lay the alkali-free yarn layer by layer to improve the strength of the FRP grating.

4. Compression mold

The stirred raw materials are poured into the mold and compacted mechanically or manually.

5. Heat curing

After the grating is heated for 20 minutes, the raw materials and yarn are fused together.

6. Cooling demoulding, mold lifting

After the above process is completed, cooling for 10 minutes demolding, mold lifting, semi-finished grating finished.

7. Grinding, painting and washing

The FRP grating is polished and washed with a layer of varnish or water.

Product packaging

Hot Searches