- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

460*250*280

-

Weight:

-

60kg-120kg, 60kg-120kg

-

Input Electricity:

-

3kw-24kw

-

Steam Output:

-

4kg/h-35kg/h

-

Steam Temperature:

-

171°C

-

Voltage:

-

230/380/415/60

-

Feed Water Valve:

-

15DN

-

Steam Out Valve:

-

15DN

-

Safety Valve:

-

15DN

-

Blowdown Valve:

-

15DN

-

Certification:

-

ISO

Quick Details

-

Core Components:

-

other

-

Place of Origin:

-

Jiangsu, China

-

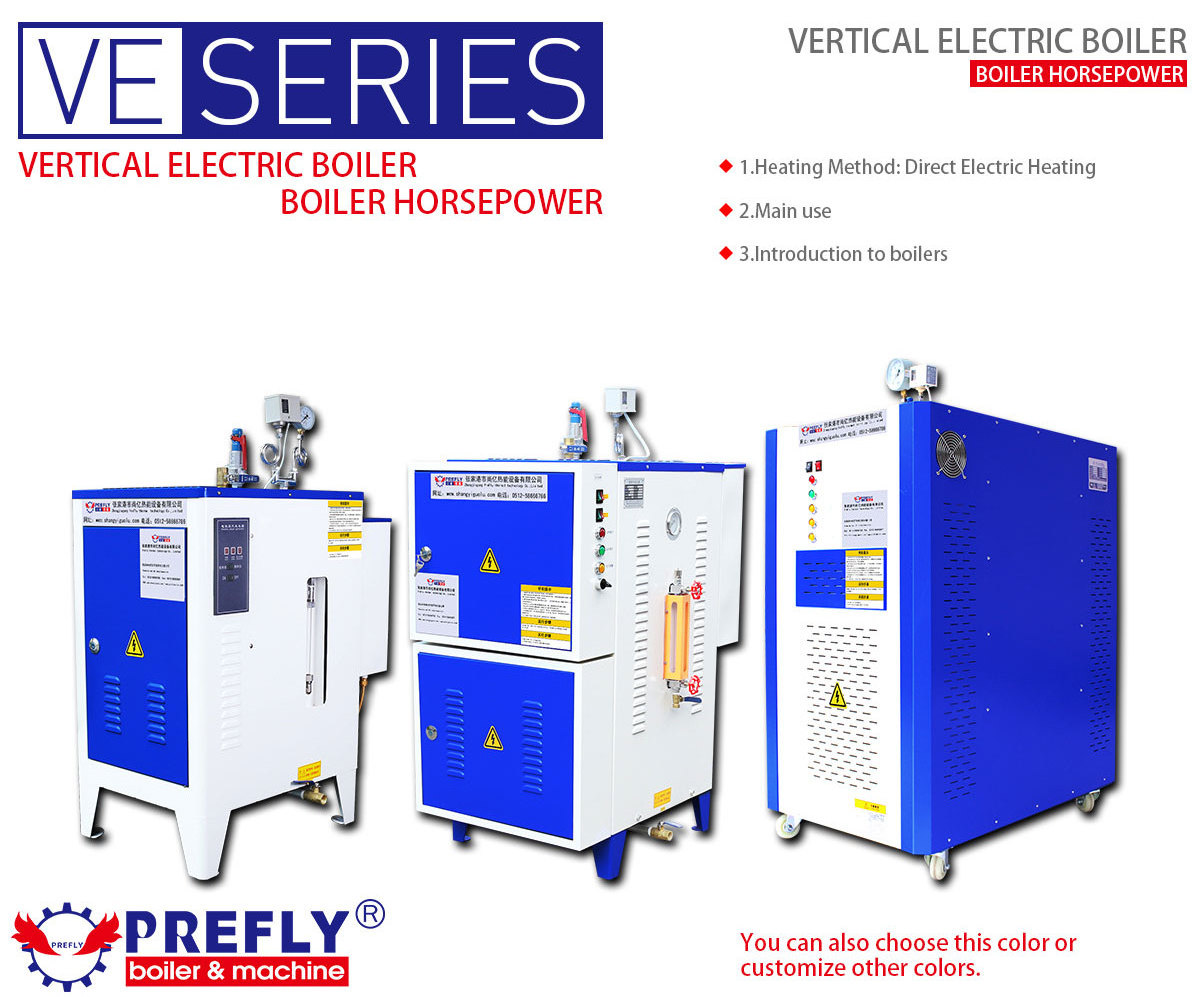

Brand Name:

-

PreFly

-

Dimension(L*W*H):

-

460*250*280

-

Weight:

-

60kg-120kg, 60kg-120kg

-

Input Electricity:

-

3kw-24kw

-

Steam Output:

-

4kg/h-35kg/h

-

Steam Temperature:

-

171°C

-

Voltage:

-

230/380/415/60

-

Feed Water Valve:

-

15DN

-

Steam Out Valve:

-

15DN

-

Safety Valve:

-

15DN

-

Blowdown Valve:

-

15DN

-

Certification:

-

ISO

Product Application

1.energy conservation steam generator Industrial intelligent design, pay attention to detail, help customers time and cost saving

2.energy conservation steam generator With its own lab, all solutions are based on experimental data

3.Safety and environment-friendly energy-saving boiler products are provided energy conservation steam generator

4.Provide 24-hour online consultation

5.More than 30 years of industry experience

6.energy conservation steam generator Customized solutions are based on your industry and respective case

7.The right solution can reduce your equipment input cost and operating costs

8.The company has a professional after-sales department to provide services 24 hours a day

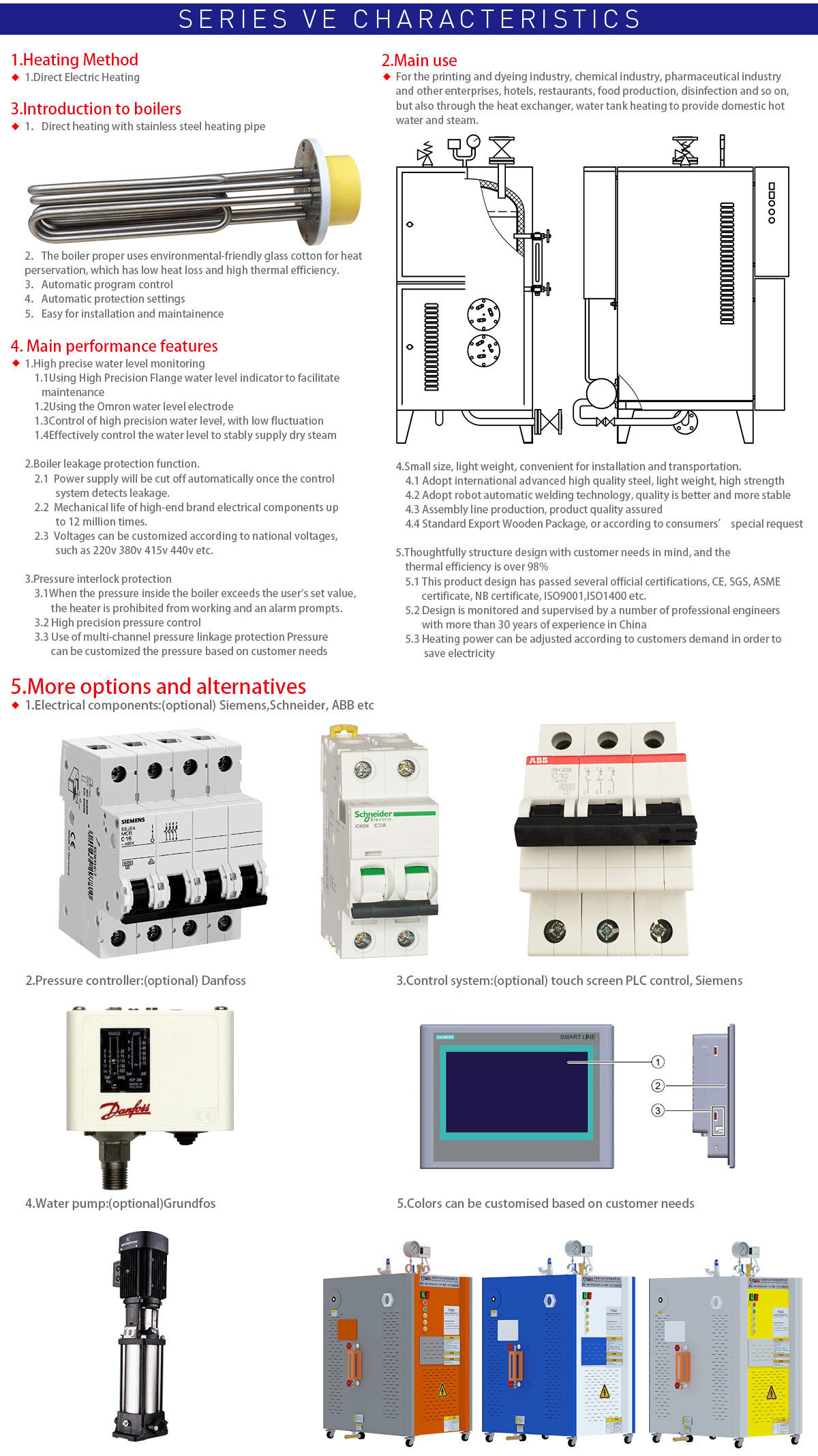

Q1: What about after sales service, such as installation and commissioning?

English manual, drawings are supplied with boiler.

Engineers are able to instruct installing and commissioning abroad.

Q2: What are the main products?

Oil fired steam boiler, capacity from 0.1t-20t

Gas fired steam boiler, capacity from 0.1-20t

Electric steam generator, capacity from 3kw-1440kw

Hot water boiler

Q3: How to insure your product quality?

(1).Strength calculation report with applied materials information;

(2).100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3).100% X-ray inspection(welding seam): ensure the quality of entire boiler;

(4).Hydrostatic test: ensure the standard working pressure and safety;

(5).Third-party inspection report;

(6).Passed ISO, ASME certifications.work experience and have done many engineering projects.