- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

according to models

-

Weight:

-

KG

-

Product name:

-

copper ore mineral dressing production line

-

Application:

-

Gold

-

Keywords:

-

Centrifugal Gold Concentrtor

-

Name:

-

China Gold Mining Equipment

-

Usage:

-

Mining Concentration

-

Installation:

-

Engineer Guide

-

Quality:

-

High Reputation

-

Feature:

-

Low Cost

-

Item:

-

Beneficiation Plant

-

Capacity:

-

1-5TPH

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Baichy

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

according to models

-

Weight:

-

KG

-

Product name:

-

copper ore mineral dressing production line

-

Application:

-

Gold

-

Keywords:

-

Centrifugal Gold Concentrtor

-

Name:

-

China Gold Mining Equipment

-

Usage:

-

Mining Concentration

-

Installation:

-

Engineer Guide

-

Quality:

-

High Reputation

-

Feature:

-

Low Cost

-

Item:

-

Beneficiation Plant

-

Capacity:

-

1-5TPH

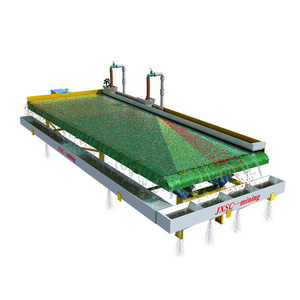

Laboratory Gold Separating Machine/Tin Mining Shaker Table Small Size Gravity Copper Shaking Table Price For Sale

Description of Shaking Table

Manganese, gold shaking table is one of the main gravity separation equipment, which is widely applied to separate tungsten, tin, tantalum, niobium and other rare metal, noble metal as well, It can also concentrate iron, manganese and coal, etc, it owns the features of high concentration ratio and sorting efficiency, easy management and adjustment, achieving the final concentrate and tailing in one time.

Applications of Shaking Table

Manganese, gold shaking table widely uses in ores such as tungsten, tin, lead, zinc, gold, silver, tantalum, niobium, monacite, zircon, ilmenite planting the fissure filling or the placer ore dressing plant in processes the 3_0.019mm granularity ore in the rough sizing and the selection work.

Features of Shaking Table:

1. Great ratio of high-grade ore, efficient separating, easy operation, easy to adjust the stroke.

2. Strong wear resistance of the working surface.

3. Anti-chemical corrosion, acid and alkali.

4. Strong resistance to harsh evironment.

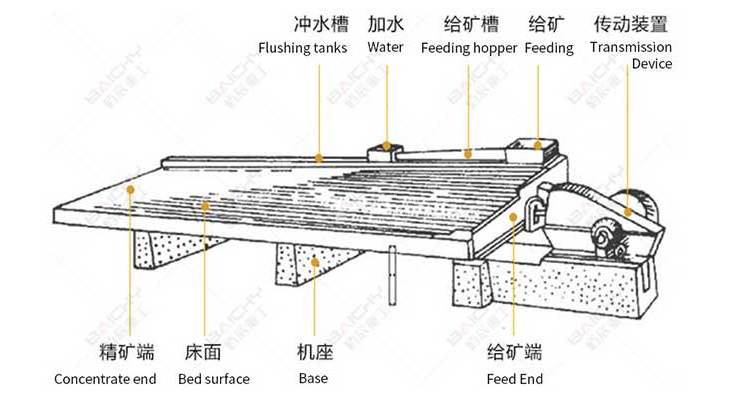

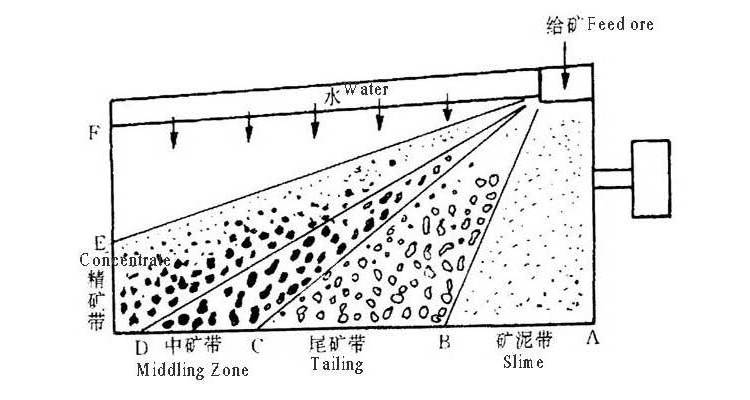

Working Principle of Shaking Table:

The manganese, gold shaking table is shaken back and forth longitudinally, using a slow forward stroke and a rapid return strike that causes particles to raw along the deck parallel to the direction of motion. The lighter materials move up and over the riffles and down to exit on the tailings side of the table. Wash water is fed at the top of the table at right angles to the direction of table movement. These forces combine to move particles diagonally across the deck from the feed end and they separate out on the table according to size and density. Tables are most commonly used to recover gold from hard rock ores, but can also be used to recover other mineral materials of higher than normal density. They do an excellent job of recovering small gold particles, even with a fairly high feed rate.| Model | Ls<6-s> | Ys |

|---|---|---|

| table structure | fiberglass reinforced plastic,embeded skeleton composit structure | fiberglass reinforced plastic,embeded skeleton composit structure |

| table size | 1500-1850×4500mm | 1500-1850×4500mm |

| selecting area | 7.5 m² | 7.5 m² |

| direction | left type and right type | left type and right type |

| slope | 0-5 degree | 0-5 degree |

| stroke | 10-30mm | 8-22mm |

| stroke number | 240-360times/min | 240-360times/min |

| feeding size | coarse sand 2-0.5mmfine sand 0.5-0.074mm slurry0.074mm | coarse sand 2-0.5mmfine sand 0.5-0.074mm slurry0.074mm |

6 Types of Gold Ore

Gold exists in quartzite. Usually, quartz appears as small stones in large cracks in riverbeds or mountain slopes and has crystals in different colors such as white, yellow, pink, purple, gray, or black. The most common types of quartz with gold ore are rose quartz gold ore and rainbow gold ore. A high gold-quartz ore contains 25% gold by mass, and it occurs in areas where the bedrock is fractured by tectonic and volcanic activity.Flow chart of gold ore processing

Placer gold ore with high gold content mostly exists in the form of particles. Therefore, the ideal method to process placer gold ore is gravity separation.

|

Jaw Crusher

|

Impact Crusher | Cone Crusher |

|

Grinding Mill

|

Baill Mill | Mobile Crusher Plant |

20 national service mileage:

Service mileage for local customers to provide equipment installation, commissioning and after-sales service

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.