- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

PNS

-

Model Number:

-

RF1000/PU PIR PUR PUF

-

Product name:

-

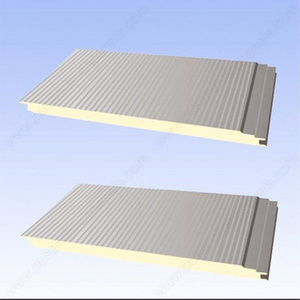

PU/PIR Sandwich Roof Panels

-

Core material:

-

Hard Polyurethane Foam

-

Thickness:

-

50mm-200mm

-

Color:

-

Customer's Require

-

Length:

-

1-11.8m

-

Width:

-

1000mm

-

Advantage:

-

Fireproof+waterproof+Insulated

-

Surface treatment:

-

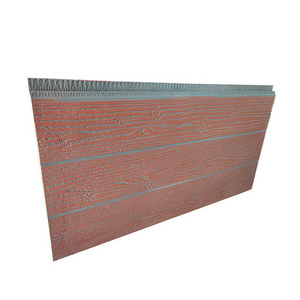

Pe Coated / SMP/HDP/PVDF

-

Usage:

-

External Wall Insulation

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Workshop

-

Design Style:

-

Industrial

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

PNS

-

Model Number:

-

RF1000/PU PIR PUR PUF

-

Product name:

-

PU/PIR Sandwich Roof Panels

-

Core material:

-

Hard Polyurethane Foam

-

Thickness:

-

50mm-200mm

-

Color:

-

Customer's Require

-

Length:

-

1-11.8m

-

Width:

-

1000mm

-

Advantage:

-

Fireproof+waterproof+Insulated

-

Surface treatment:

-

Pe Coated / SMP/HDP/PVDF

-

Usage:

-

External Wall Insulation

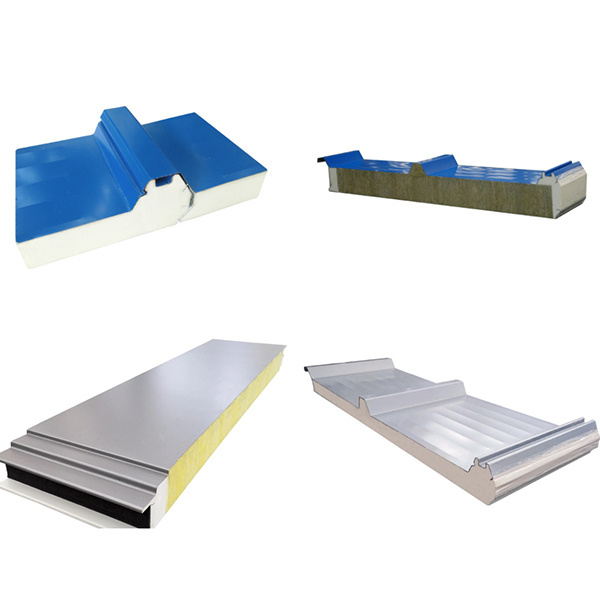

Advantages of roof panels:

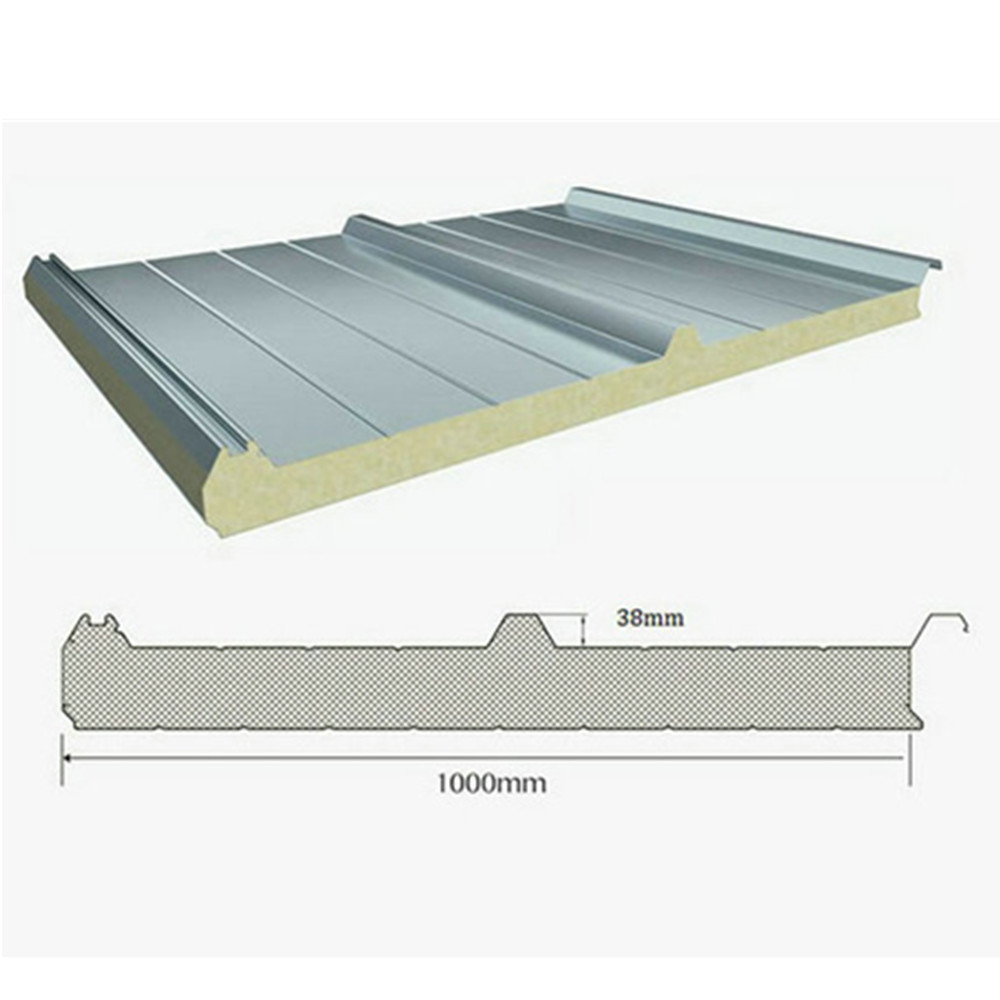

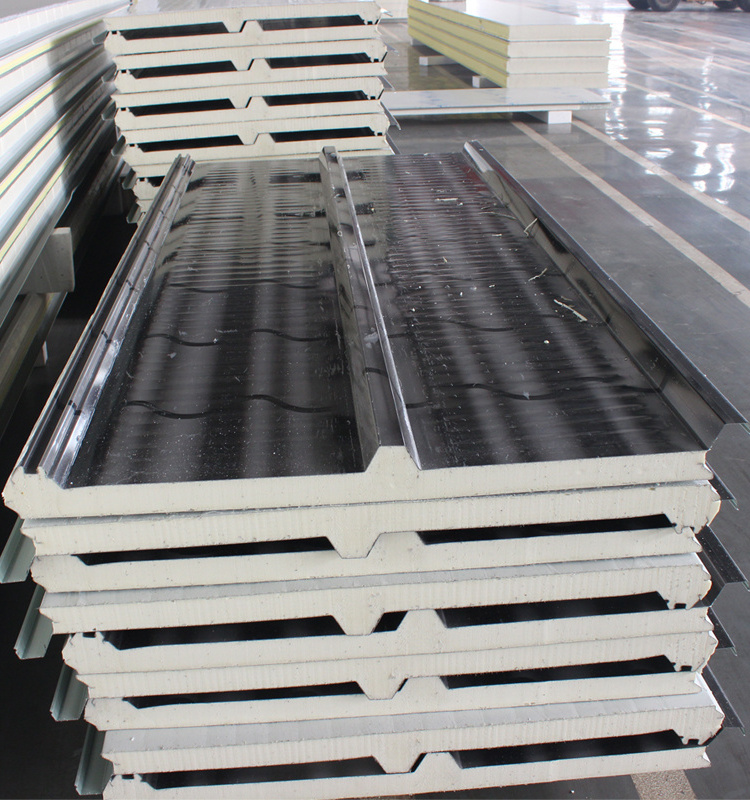

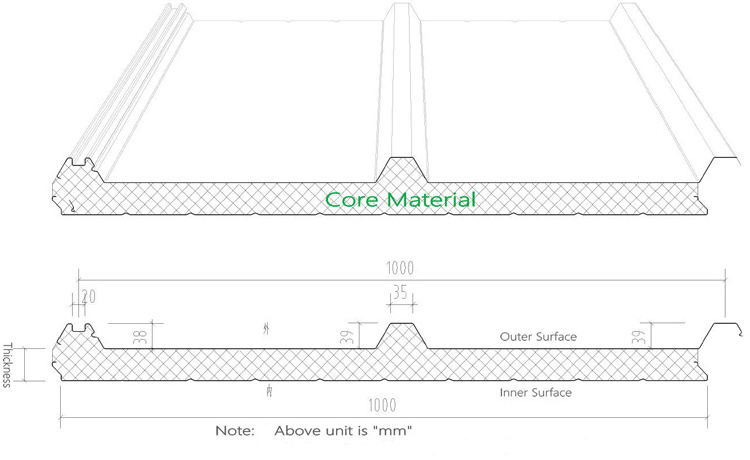

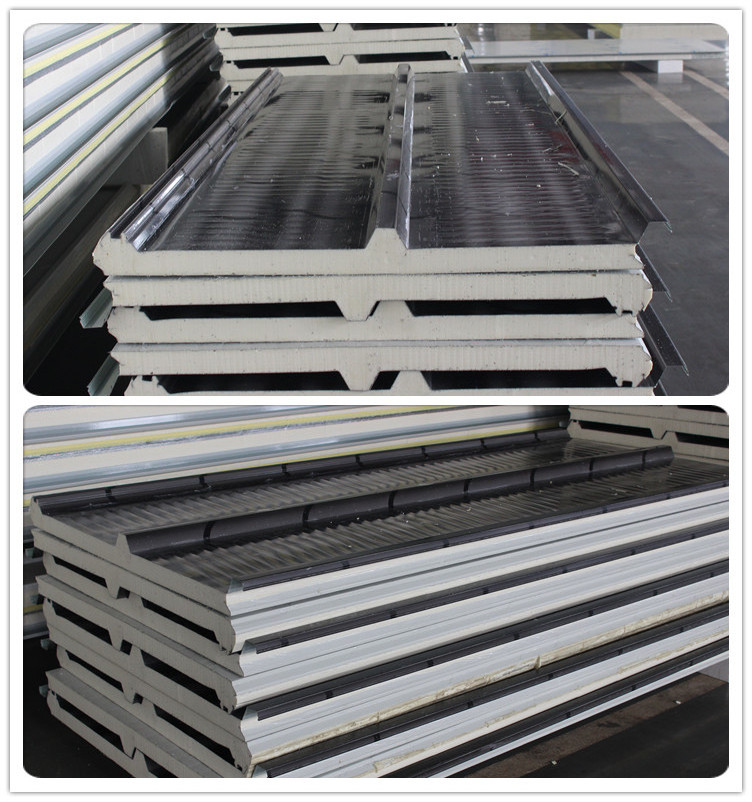

1). The panels are connected by hidden screws,joint tight and no heating conduction by screw which covered by panel and no any rust and rain leakage at all.

2).The unique capillary groove design effectively avoids rainwater seepage and cold bridge phenomenon.

3) .The peak height of 40mm improves the bearing capacities of roof plates greatly. The heat preservation effects of buildings are ensured and the building costs of customers are significantly decreased as well,The minimum roof pitch may be 3%.

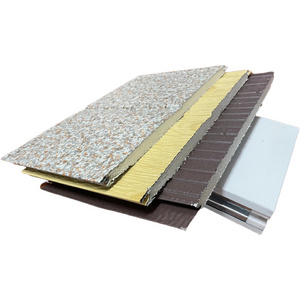

PUR Introduction :

In terms of raw material proportioning and process output,

our

PUR products employ the globally advanced six-component online automatic operation mixing and pouring technology and have realized six-component continuous foaming for the first time in China.With the technology,mixing and proportioning process may be finished in an online way ; the formula may be adjusted according to environmental changes;air feeding and mixing devices may be used to make raw material mixing more even and foam finer

,

thus producing high-strength ,energy-saving and environment friendly building boards

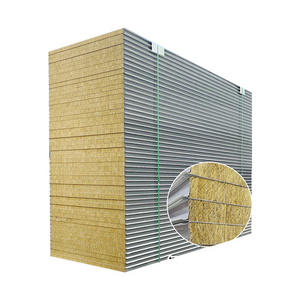

PIR Introduction :

POILISOCYANURATE is called PIR for short. For the composite boards developed,excessive isocyanurate is added and ring structure and higher isocyanurate index are employed in the compounds to form compact PIR products, thus ensuring greater stability and excellent heat and fire resistance for the internal rigid foams . Experiments show that the products may endure a temperature up to 200℃ in short time or to 160℃ for long time .

Specification :

|

Product Name |

P U/PIR Sandwich Roof Panel |

|

Thickness of panels |

50/60/70/75/80/100/120/150/200mm |

|

Core material |

P U/PIR |

|

Thermal conductivity of PU/PIR |

≤0.026w/(m. k) |

|

Density of core material |

38-42 KG/M 3 |

|

Height of major rib |

39mm |

|

Thickness of Exterior/ interior face |

0.4-0.8 mm |

|

Effective width |

1000 mm |

|

Length of panel |

Max.11.8 meters |

|

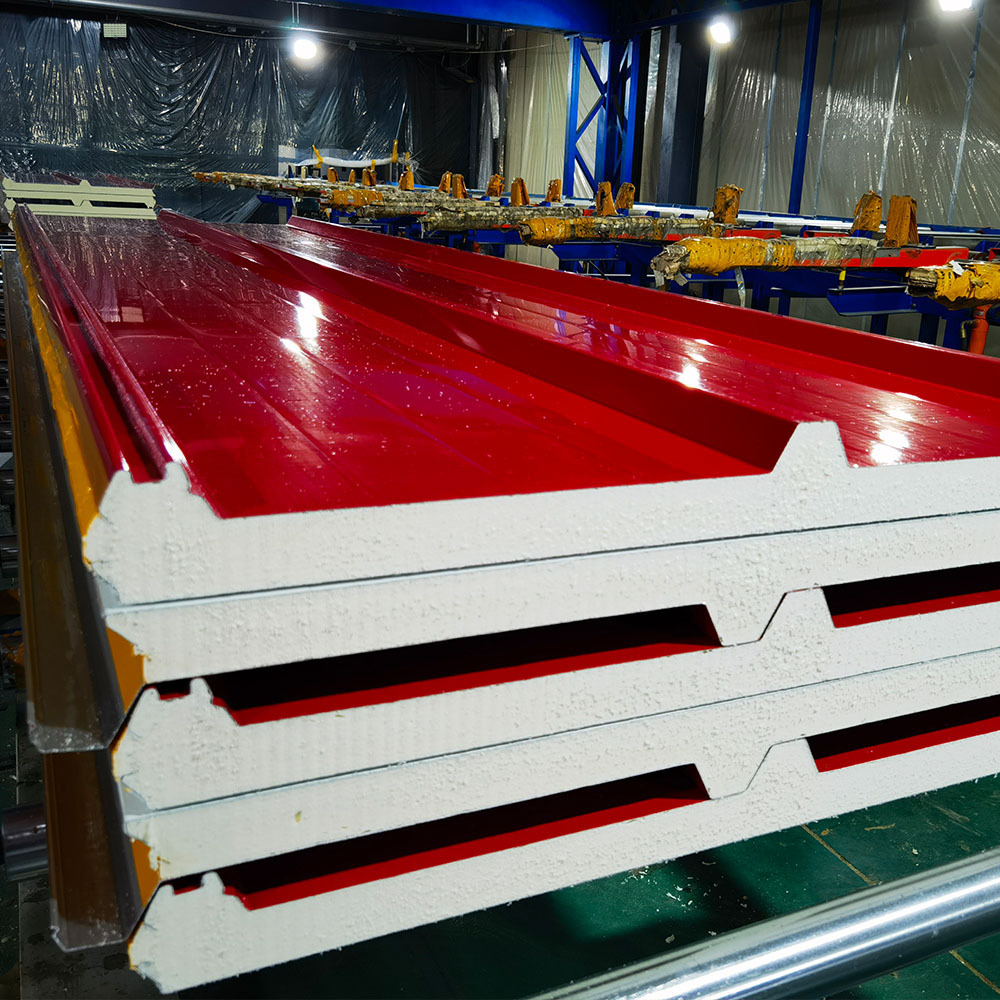

Color of steel plate |

White grey,silver gray,sea-blue,crimson and so on |

|

Painting |

Polyester PE/SMP/HDP/PVDF coating etc. |

|

Coating |

Hot dip zine coating,hot dip aluminum-zin coated |

|

Recommended steel coil supplier |

Baosteel,YIEH PHUI,BLUESCOPE etc. |

|

Connection |

tongue and grouve with hidden screw Joint |

Our company located in Henan,China.Factory built more than10 years ago, 1.2 million square meter sandwich panels for Annual output.5-8m /Min.for produce speed.Amount of sales is 120 million RMB(About USD 19 Mil.) include China market and overseas market.

Our sandwich panel production line is an automatic production line, which is consisting of decoiling , film coating,cutting equipment ,roll forming system,preheating, foaming, solidification, band saw cutting, cooling, stacking and packing. The whole line integrates mechanics, chemistry, electrical control and hydraulic press with pneumatic temperature control.Our production equipment is imported from Italy (SAIP brand).24hour can produce 8000m2.