- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Qingdao Century Haijia Machinery

-

Dimension(L*W*H):

-

4450*2005*1500

-

Weight:

-

4000 KG

-

Power:

-

3.7KW

-

Textile machinery:

-

Yarn Spinning Textile Machine

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Application:

-

Yarn

-

Production Capacity:

-

HIGH SPEED

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Qingdao Century Haijia Machinery

-

Dimension(L*W*H):

-

4450*2005*1500

-

Weight:

-

4000 KG

-

Power:

-

3.7KW

-

Textile machinery:

-

Yarn Spinning Textile Machine

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Technical Parameters

|

|

1

|

The Effective reed width(cm)

|

Normal reed width: 0---65cm(≤230cm); 0---85cm(>230cm)

|

|

2

|

Starting mode

|

Motorized spindle; Super start motor drive(Optional)

|

|

3

|

Motor capacity

|

2.2KW、 2.7KW、 3.0KW、 3.7KW、 4.5KW、 6.0KW

|

|

4

|

Running operation

|

One-hand operation button; Two-hand operation button(Optional)

|

|

5

|

Pump

|

Single pump; Double pump(Optional)

|

|

6

|

Nozzle

|

Normal Nozzle, "U" shaped Nozzle

|

|

7

|

Crank shedding

|

4-piece type; 6-piece type; 8-piece type(Optional)

|

|

8

|

Positive cam shedding

|

6,8,10 piece type,12,14 piece type(Optional) |

Product Overview

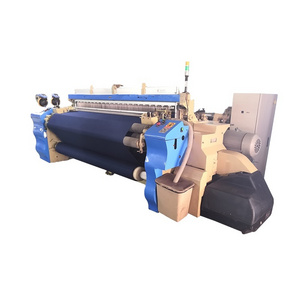

Haijia 150 Width Textile Weaving Machine

HW-8010

Series Water Jet Loom

HW-8010

series water jet weaving has been extensively strengthened in the fuselage;

Adapt to the weaving of most fabrics; such as interlining, taffeta, umbrella cloth, bag cloth, etc.

It has also been greatly improved in terms of waterproofing, and can be widely used in the weaving of various fabrics. The maximum speed can reach 1000RPM.

Taking 75D fabric as an example, the highest weft density is 50 shuttles/cm (127 threads per inch)

Products Show

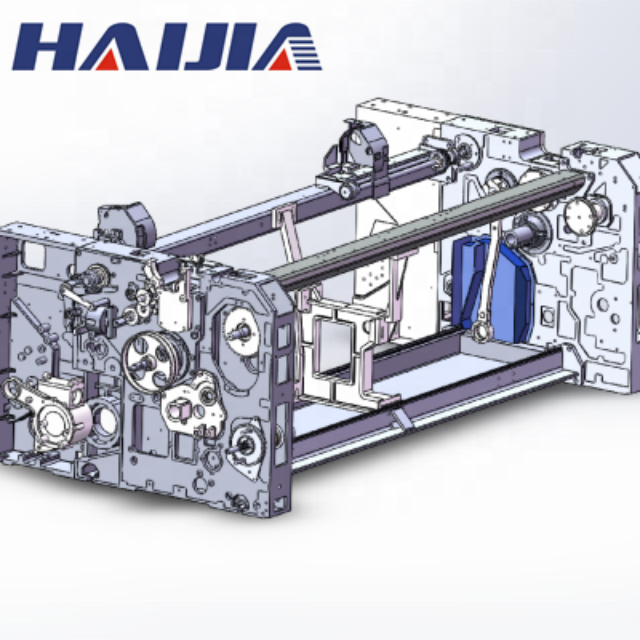

Frame System

The reinforced integrated machine wall board is made by one complete casting which highly improves the frame rigidity and reduces the vibration and noise pollution. Connected with cross beams and middle supporting beam, the re-designed two machine wall boards are firmly jointed together in 20mm lower height which is more suitable for machine operators to manage.

Electronic Let-Off

The total tension of the warp is detected by the tension sensor. The CPU handles the change of the warp tension caused by the opening or the change of the loose warp, let off warp and the winding diameter of the warp shaft, and commands the servo motor to drive the warp shaft, so as to maintain the balanced tension during the working process, eliminate the loose and dense gear, and ensure the stability of the fabric tension.

Weft Insertion System

In order to reduce weaving costs and better protect the environment, splash proof "U" nozzles are widely used. Compared with ordinary nozzles, splash proof "U" nozzles have better water line bunching performance. Plunger with smaller diameter is used to achieve stable operation under small opening weft insertion and small water volume. A single loom can save 10% water, which is widely applicable to weaving fine denier, high-density and high-speed fabrics.

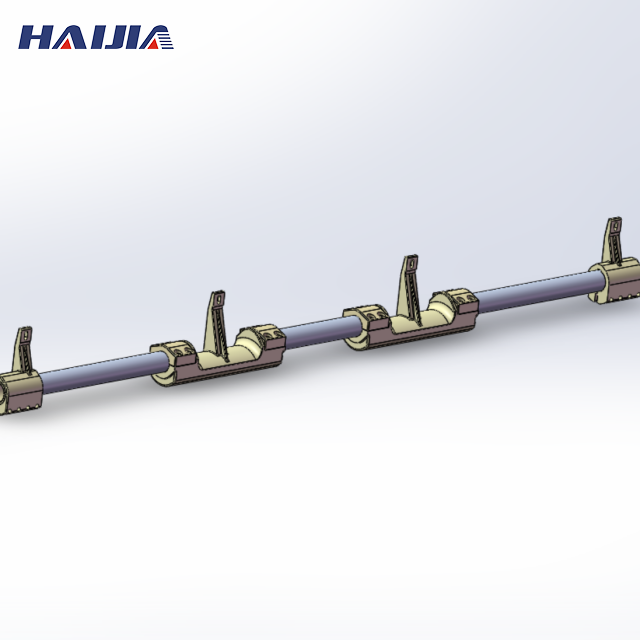

Beating-up System

The optimized beating-up system achieves shorter stroke with low vibration which is designed in modern style on the basis of motion analysis and dynamic equilibrium analysis. The independent developed U type solid beating shaft and beating shaft counter balance system can be used for both narrow machine and wide machine. The small stroke4-linkage beating system is widely acknowledged akconologed for narrow machines while 6-linkage beating system with longer relative static time and stronger beating force provides the best choice for wide machines to make wide and high density fabrics.

Electric control

Using motorized spindle with no brake disc, which saves more than 20% electricity; by working with the new optimized control syster im, the stepless speed change can be achieved.

Selvage System

It provides larger opening to reduce weft blocking and increase the machine efficiency. With separate selvaging device, it can catch the weft by its own device instead of catching the weft by the movement of two extra heald frames.

Hot Searches