- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Compact Vacuum Arc Melting Furnace

-

Max temperature:

-

4000C

-

Cavity material:

-

Stainless steel

-

Observation window:

-

High Purity Quartz

-

Input Power:

-

6kw

-

Electrode:

-

dia 4mm

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

SCK

-

Place of Origin:

-

Henan, China

-

Product name:

-

Compact Vacuum Arc Melting Furnace

-

Max temperature:

-

4000C

-

Cavity material:

-

Stainless steel

-

Observation window:

-

High Purity Quartz

-

Input Power:

-

6kw

-

Electrode:

-

dia 4mm

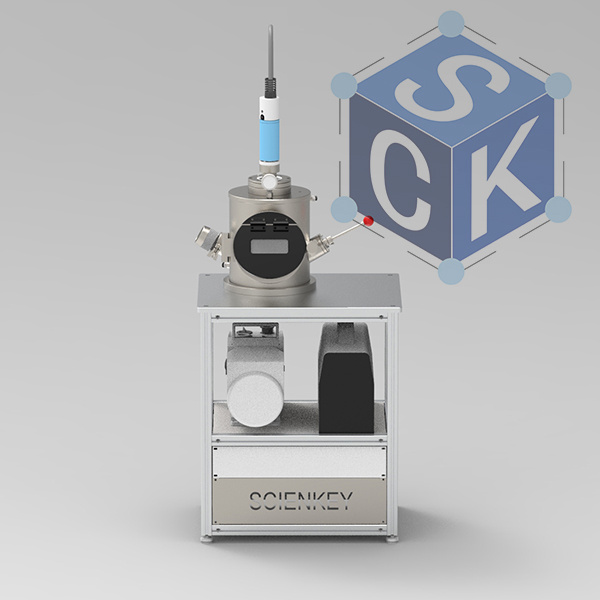

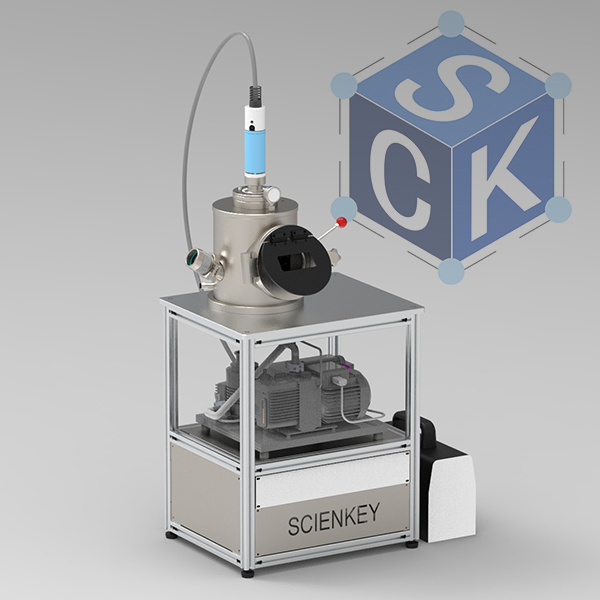

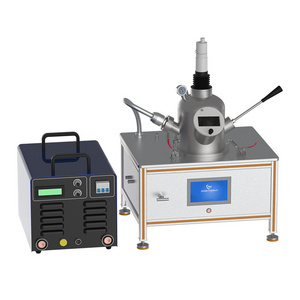

Factory sells 3000℃ vacuum arc melting furnace/vacuum melting casting furnace with complete accessories

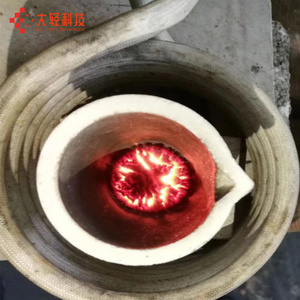

our company made Compact Vacuum Arc Melting Furnace with non-consumable tungsten electrode and water cooled copper crucibles. Integrated mechanical manipulator can repeatedly tilt/rotate multiple metal ingots for remelting process. It is an excellent tool for smelting metal alloys with elevated mechanical homogeneity under protective gas environment. This equipment utilizes the high temperature produced by the electrode arc to smelt ores and metals in an electric furnace. When the gas discharge forms an arc, the energy is very concentrated, and the temperature of the arc zone is above 3000 °C. For metal smelting, the electric arc furnace is more flexible than other steelmaking furnaces, and can effectively remove impurities such as sulfur and phosphorus. The furnace temperature is easy to control, and the equipment occupies a small area.It is suitable for the melting of high-quality alloy steel.

(Support customization, including accessories and consumables, please contact our staff for details.)

specifications

|

Features |

Φ120mm front door for easy sample loading/unloading A tinted observation window is installed on the front for instant monitoring of the entire melting process. Water cooled vacuum chamber(φ300mm × 320mmH), cold copper crucible and electrode Electrode position (height) adjustment via hand wheel turning Integrated mechanical manipulator made of stainless steel 1Cr13 can repeatedly tilt/rotate multiple metal ingots without breaking the vacuum Water cooled copper hearth allow smelting multiple samples without cross contamination upto 3000°C |

|

Vacuum Pressure Gauge |

Please select the anti-corrosive capacitance diaphragm gauge or mechanical vacuum pressure gauge from option bar. Digital pressure gauge is used for vacuum chamber Mechanical pressure gauge is used when continuous flow of inert gas inside the chamber |

|

Power supply |

Input Voltage: Single phase AC 220V+/- 15% . 50/ 60Hz (Three Phase AC 380V 50Hz is available upon request) Input Power: 6.3KW, 30A Max. Output Power DC, 56V (OVC), 10 - 190A max. adjustable Optional: larger current upto 300A is available at additional cost. |

|

Max. Temperature |

~ 4000°C , almost can melt all type metal ( < 10 g ) Bottom-left picture is a 4.5 g tungsten melt drop Bottom-right picture is a 10g tungsten melt drop |

|

Vacuum Chamber & Copper Hearth |

Vacuum chamber: Φ200mm×350mm, made of stainless steel with water cooling jacket Water cold copper hearth with 7 crucibles of 25mm dia.x 8 mm depth Solidified sample is about 20 mm half-round button in max. and sample weight is depended on material density. Customized copper hearth is available upon request Sample weight for each crucible can be estimated as: W (g) = 2/3 π r3 d ( d= density, g/cm3) |

|

Electrode |

4 mm dia. Tungsten electrode with water cooling Top hand wheel can move electrode cycle, upward and downward ( max. 30 mm) to melt seven sample in one batch |

|

Water Chiller & Gas (Optional) |

Water cooling is required ( not included ) for its chamber, copper mold and electrode. Please consider to use the KJ-5000 recirculating water chiller. High purity Ar gas is required ( not included ). You may use 5% H2 + 95% Ar gas to better reduce oxidation |

Our company is engaged in the development and application of material-related research and development equipment and lithium battery experimental equipment. After years of accumulation, Zhengzhou Seji has become an overall solution planner for basic research, small and pilot tests, testing and evaluation of new energy and new materials. and suppliers, product applications cover composite materials, advanced oxides, metallurgical functions, amorphous refractories, graphene materials, advanced ceramics, advanced nanomaterials, lithium-ion batteries, supercapacitors, fuel cells, solid-state batteries, perovskites Solar cells, functional films, etc. Mainly used for small-scale production in colleges and universities, scientific research institutions, laboratories and factories

Company purpose:

High-quality products, advanced services, forge ahead, industry-leading.

Realize one-stop service of R&D, production, sales, logistics and after-sales