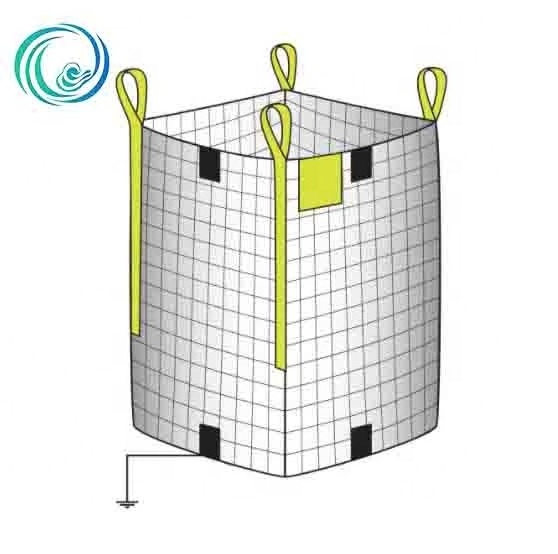

Conductive bags shall have a derivation resistance to earth bonding points of less than 10x10

8

Ω and shall be constructed from fabrics having a breakdown voltage of less than 6000V .

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QINFENG

-

Model Number:

-

QFJ4-22-0601

-

Product name:

-

PP Woven Electrically Conductive Jumbo Bags Type C

-

Material:

-

100% Virgin Polypropylene

-

Usage:

-

Industrial Packing

-

Size:

-

90*90*120cm Custom Size Accepted

-

Bag Type:

-

Circular/u-panel/4-panel/baffle

-

Color:

-

Customer's Request

-

Loop:

-

4 Side-Seam Loop

-

Printing:

-

3 Color Printing

-

Sample:

-

Free Samples Provided

-

OEM:

-

Accecptable

Quick Details

-

Feature:

-

ANTISTATIC

-

Loading Weight:

-

1500kgs

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QINFENG

-

Model Number:

-

QFJ4-22-0601

-

Product name:

-

PP Woven Electrically Conductive Jumbo Bags Type C

-

Material:

-

100% Virgin Polypropylene

-

Usage:

-

Industrial Packing

-

Size:

-

90*90*120cm Custom Size Accepted

-

Bag Type:

-

Circular/u-panel/4-panel/baffle

-

Color:

-

Customer's Request

-

Loop:

-

4 Side-Seam Loop

-

Printing:

-

3 Color Printing

-

Sample:

-

Free Samples Provided

-

OEM:

-

Accecptable

Product Description

|

Product Name

|

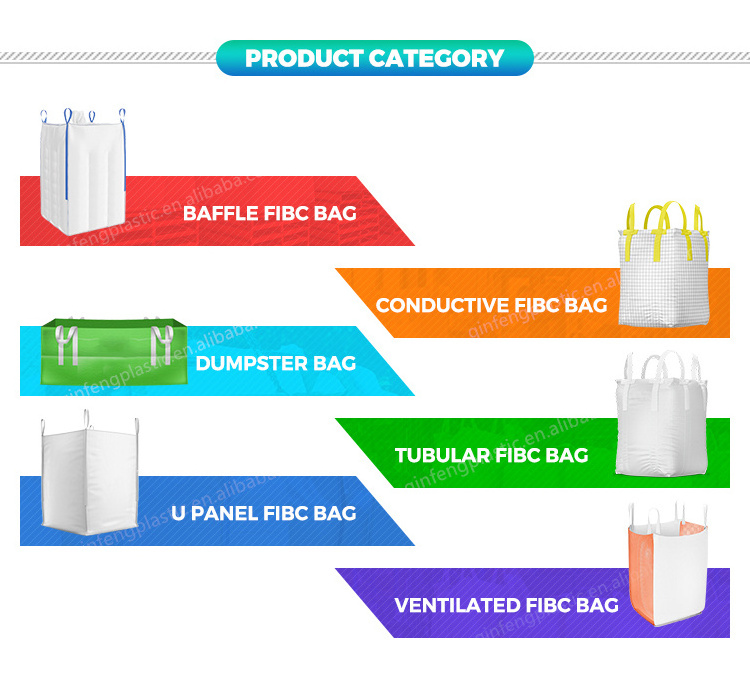

Type C 500kg waterproof UV FIBC electrically conductive Bags PP Dangerous chemicals Packaging bag 1500 kg pp woven jumbo bag

|

|

More Key words

|

1 Ton Bulk Liquid Packing Bulk Container Foldable FIBC Container

Reusable 1000 kg Bulk Big Bag Grain Bags Food Bulk Container Liner Bags

Heavy Duty Dumpster Bag Industry Jumbo Skip Bag for Building

Construction Waste skip Bag Garden Waste Bags packing

|

|

Bag Type

|

Tubular/U-pabel/Baffle/Dumpster Skip bags/Fully Loops Bags

|

|

Filling Spout

|

Duffle Top/Top skirt/Full open /Star closer

|

|

Discharge Spout

|

Flat Bottom/Discharge spout/petal discharge spout/star closer

|

|

Loops

|

Single Loop ;two loops ,cross corner loops;side seam loops;Fully bottom loops ;Tunnel loops ;Acceptable customized bag type as client's requests

|

|

Safety Working Loading

|

500kg-2000kg

|

|

Safety Factor

|

3:1/4:1/5:1/6:1

|

|

Liner

|

Can be as client's request

|

|

Printing

|

3 colors or as Client's request

|

|

Packing

|

100-200pc/bale;pallet ;as client's request

|

|

Document Pocket/Label

|

PP/PE ;Custom Document pocket /Label or as client's request

|

|

Samples

|

Free samples provided ;

|

TYPE C BIG BAGS (CONDUCTIVE BIG BAGS)

TYPE C BULK BAGS

FIBC Type C are made from fabrics that have inter-connected static dissipative or conductive threads, which is why they're known as conductive FIBC or groundable FIBC. Originally they were made from entirely conductive materials, but now groundable Type C FIBC are more commonly made from non-conductive polypropylene interwoven with conducting yarns, normally in a grid pattern. The conductive yarns must be electrically interconnected and connected to designated ground or earth bonding points. The ground or earth bonding points must in turn be connected to a system ground or earth during all bulk bag filling and emptying operations.

|

Capacity

|

Empty Size

(W*L*H)

|

Filled Diameter

|

Applications

|

|

5 to 20 cubic feet

|

20" X 20" X 31"

|

38"

|

Used for higher bulk density products or smaller weight requirements.

|

|

21 to 75 cubic feet

|

35" X 35" X 37"

|

46"

|

Most common for all products. Used in truck shipments and export containers.

|

|

76 cubic feet and up

|

41" X 41" X 43"

|

53"

|

For smaller bulk density products where height restrictions occur. Used for rail shipments

|

FIBC Type C Requirements

preforms tests to meet Type C bulk bag requirements including electrical breakdown voltage and propagating brush discharge testing. Type C bulk bags also require testing for resistance to ground-able point.

ABOUT PRODUCT:

1. What is a Duffel Top FIBC Jumbo Bag?

Duffel top is a thin lightweight top panel, who has the same width and depth as the four sides of the bag. The larger opening is more flexible in filling, also offers more options of the types of filling machinery. After filling the duffel top can be closed

to protect the contents of the bag and it is safer when transport.

2.What is a Spout Top FIBC Jumbo Bag?

Spout top is a sturdy spout sewn to the top panel of the FIBC bag. It is cylindrical and narrower than the width and depth of the bag. This smaller opening isn’t as flexible as the duffel top but is better for specific machinery and applications. The smaller opening allows for less dust in and product spill during filling. The spout can also be tied off to protect the product during transportation and storage.

3.What are FIBC Jumbo Bags made of?

Standard FIBC Jumbo Bag and Lifting Loops are made from 100% new woven polypropylene fabric commonly known as PP. Liners are typically made from polyethylene commonly known as PE.

4.How to fill/ discharge FIBC Jumbo Bag?

Filling: Generally through a filling spout located on the top.

Discharging: Usually through the unloading spout located at the side or bottom of the bag, or by slitting the bottom of the bag.

5.How to transport FIBC Jumbo Bags?

When full loading, the bag is transported via top straps (with a forklift), a pallet (with a pallet jack or forklift), or

stevedore straps (with a crane hook or adapter).

6.When should I choose Baffle type FIBC Jumbo Bag?

Food applications, fine powders, moisture sensitive products, and products that would require oxygen or vapor barriers would all be good candidates for liners.

7. What size of FIBC Jumbo Bag do I need?

Depends on your product's parameter and the transportation way you prefer.

8. What information need to provide for quotation?

Please provide your products' drawing(if you have), size, loading capacity, quantity, logo printing, destination port.

ABOUT SERVICE:

9.If I have large quantity, can you give me a discount?

Yes, of course. If the quantity is more than 3000pcs, we'll give you a more favorable price.

10. Before placing the order, can I visit your factory?

Yes, warmly welcome. Before you come, please let us know your schedule, your arriving time, we can help to pick you up at nearby airport or railway station.

11. What is your products advantage?

High quality, competitive price, best service, our products in the United States and other developed countries is very popular,

has been recognized by customers around the world.

12.What’s the delivery time?

30 days for 20GP; 45 days for 40 HQ; communicate with us for urgent or small orders, usually in 10~30 days!

13.What’s your sample policy?

We can provide 1-2pcs sample bag for free! Only the courier charges is paid by customers.

14. Can you customize? If so, what’s your MOQ?

We do offer OEM Services with 500PCS for tubular bags, 300PCS for U Panel type bags. Contact us for special bags of Type B/C/D.

15. What’s your guarantee for quality?

Responsible quality test, sample is detected piece by piece for at least two times. Third party detection report could be offered for customer’s evaluation!

OTHERS:

16.What is the MOQ ?

For bigger size, the MOQ is 500pcs for each design

For smaller size, the MOQ is 1000pcs for each design

17. What is the order process for a new customer or application?

(1) Confirm bag's specification.

(2) Confirm price.

(3) Sample bag delivery.

(4) Place formal order and pay the advance payment.

(5) Confirm printing(if have)

(6) Finish production.

(7) Goods delivery.

1. What is a Duffel Top FIBC Jumbo Bag?

Duffel top is a thin lightweight top panel, who has the same width and depth as the four sides of the bag. The larger opening is more flexible in filling, also offers more options of the types of filling machinery. After filling the duffel top can be closed

to protect the contents of the bag and it is safer when transport.

2.What is a Spout Top FIBC Jumbo Bag?

Spout top is a sturdy spout sewn to the top panel of the FIBC bag. It is cylindrical and narrower than the width and depth of the bag. This smaller opening isn’t as flexible as the duffel top but is better for specific machinery and applications. The smaller opening allows for less dust in and product spill during filling. The spout can also be tied off to protect the product during transportation and storage.

3.What are FIBC Jumbo Bags made of?

Standard FIBC Jumbo Bag and Lifting Loops are made from 100% new woven polypropylene fabric commonly known as PP. Liners are typically made from polyethylene commonly known as PE.

4.How to fill/ discharge FIBC Jumbo Bag?

Filling: Generally through a filling spout located on the top.

Discharging: Usually through the unloading spout located at the side or bottom of the bag, or by slitting the bottom of the bag.

5.How to transport FIBC Jumbo Bags?

When full loading, the bag is transported via top straps (with a forklift), a pallet (with a pallet jack or forklift), or

stevedore straps (with a crane hook or adapter).

6.When should I choose Baffle type FIBC Jumbo Bag?

Food applications, fine powders, moisture sensitive products, and products that would require oxygen or vapor barriers would all be good candidates for liners.

7. What size of FIBC Jumbo Bag do I need?

Depends on your product's parameter and the transportation way you prefer.

8. What information need to provide for quotation?

Please provide your products' drawing(if you have), size, loading capacity, quantity, logo printing, destination port.

ABOUT SERVICE:

9.If I have large quantity, can you give me a discount?

Yes, of course. If the quantity is more than 3000pcs, we'll give you a more favorable price.

10. Before placing the order, can I visit your factory?

Yes, warmly welcome. Before you come, please let us know your schedule, your arriving time, we can help to pick you up at nearby airport or railway station.

11. What is your products advantage?

High quality, competitive price, best service, our products in the United States and other developed countries is very popular,

has been recognized by customers around the world.

12.What’s the delivery time?

30 days for 20GP; 45 days for 40 HQ; communicate with us for urgent or small orders, usually in 10~30 days!

13.What’s your sample policy?

We can provide 1-2pcs sample bag for free! Only the courier charges is paid by customers.

14. Can you customize? If so, what’s your MOQ?

We do offer OEM Services with 500PCS for tubular bags, 300PCS for U Panel type bags. Contact us for special bags of Type B/C/D.

15. What’s your guarantee for quality?

Responsible quality test, sample is detected piece by piece for at least two times. Third party detection report could be offered for customer’s evaluation!

OTHERS:

16.What is the MOQ ?

For bigger size, the MOQ is 500pcs for each design

For smaller size, the MOQ is 1000pcs for each design

17. What is the order process for a new customer or application?

(1) Confirm bag's specification.

(2) Confirm price.

(3) Sample bag delivery.

(4) Place formal order and pay the advance payment.

(5) Confirm printing(if have)

(6) Finish production.

(7) Goods delivery.

Hot Searches