- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v/400v/440v

-

Power:

-

According to the solution

-

Dimension(L*W*H):

-

According to the solution

-

Weight:

-

60000 kg, According to different model

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Turn Key Basis:

-

Yes

-

History:

-

60 years

-

Certification:

-

ISO9001:2008 /CE

-

Diameter/Length:

-

2.5/40-3/60

-

Spare parts supply:

-

Anytime

-

Test&Installation:

-

Under Enginees Guidence

-

Thickness:

-

40mm-60mm

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZK brand

-

Voltage:

-

220v/380v/400v/440v

-

Power:

-

According to the solution

-

Dimension(L*W*H):

-

According to the solution

-

Weight:

-

60000 kg, According to different model

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Turn Key Basis:

-

Yes

-

History:

-

60 years

-

Certification:

-

ISO9001:2008 /CE

-

Diameter/Length:

-

2.5/40-3/60

-

Spare parts supply:

-

Anytime

-

Test&Installation:

-

Under Enginees Guidence

-

Thickness:

-

40mm-60mm

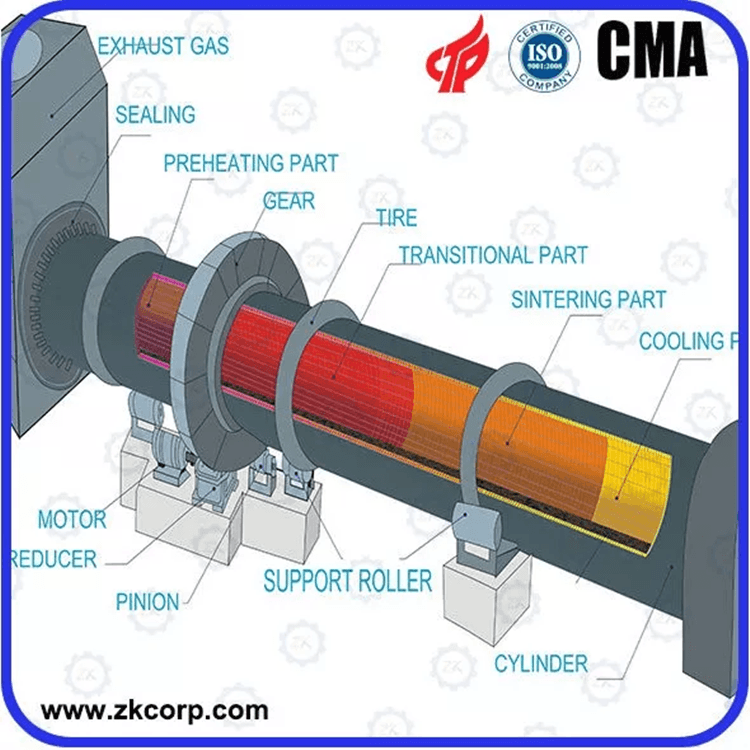

[Introduction]

Zinc oxide rotary kiln

is the calcination equipment used for processing the zinc-bearing materials to get the zinc oxide. The zinc oxide rotary kiln manufactured by ZK Corp. is specialized used and designed for the production of zinc oxide, as the zinc oxide exists in powdery. Because the zinc oxide is very fine powder, so we have to make a special rotary kiln for zinc oxide production, that is what we say now “zinc oxide rotary kiln”.

[Application]

Mainly used in building materials, metallurgy, chemical, refractory materials, environmental protection industries, chemical products - water zinc sulfate, zinc sulfate heptahydrate, refractories, the zinc oxide is the main raw materials for the production of steel-making zinc ball. For Building construction, it is widely used in the production for containers, fire board, arts and crafts, vegetable greenhouses, wall insulation board, activity board, asbestos etc. Because of good adsorption, low melting point, so it is also used for paint coatings refractory bricks, magnetic materials, ceramics, rubber tires etc.

[Working Principle]

Zinc oxide rotary kiln working principle is the whole process and principles of the calcined zinc, zinc-containing materials. Generally it adopts the zinc oxide rotary kiln to process of the zinc-containing filter cake. The zinc in the filter cake mainly exists in the form of zinc ferrite, oxide and sulfate. Under the high temperature in the rotary kiln, the zinc ferrite and solid carbon will produce the reaction for oxide-reduction, then it will get the zinc, at the same time lead and cadmium sulfate also be reduced, will volatilize in the form of sulfide and gold bucked out. The reduced and volatilized metal from the solid phase will be re-oxidation, and finally will be produced in the form of oxide.

Note: The amount of air into the zinc oxide rotary kiln should ensure that the flue gas has sufficient oxygen to re-oxidize all the metal vapor, sulfide and carbon monoxide. Increasing the amount of air in the zinc oxide rotary kiln will increase the recovery zone to the feed end. On the contrary reducing the amount of air, the reduction area is shortened and the starting section of the reduction zone extends toward the discharge end.

| Model | Kiln size | Motor Power | Total weight | ||||

|---|---|---|---|---|---|---|---|

| (m) | Diameter(m) | Length(m) | Slope(%) | Capacity(t/d) | Rotating speed(r/min) | (kw) | (t) |

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 201.94 |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| Φ3.0×60 | 3 | 60 | 4 | 800 | 0.3-2 | 100 | 310 |

Our process system and equipment products are sold well in all provinces and regions in China, and has been exported to Russia, South Korea, the United States, Canada, Japan, Britain, Saudi Arabia, Vietnam, Thailand, Indonesia, Malaysia, Nepal, Bangladesh, Mexico, Kazakhstan, Turkey, Iran, Guatemala, India, Mongolia, Africa, South America and many other countries and regions, which have been well received by our clients .

1. Excellent installation team or installation service for you;

2. Provide you with operating and training services;

3. Help with the equipment commissioning and solve problems in trial operation;

4. Check before

acceptance of single equipment or whole production line;

5. Service items including follow-up visit, customer satisfaction surveys and so on;

6. Timely provide you with necessary accessories after acceptance;

7. Provide you with warranty services of repair, replacement and refund if conditions are fulfilled

;

8. Help you solve other problems.