2.The error message is displayed on the screen to help the operator clear it immediately.

- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

adjustable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

zhuoran

-

Year:

-

2019

-

Power (kW):

-

4

-

Weight (KG):

-

800

-

Bend way:

-

Servo bend

-

Feed servo motor:

-

750w

-

Corner servo motor:

-

400w

-

left and right mold change servo motor:

-

400w

-

bend servo motor:

-

1.5kw

-

Pipe fittings allow elbows:

-

50

-

Number of parts that can be stored.:

-

500

-

Machine dimensions.:

-

2500*700*1300

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machine Type:

-

Pipe Bending Machine

-

Bending Radius (mm):

-

10 - 180

-

Max. Bending Angle (Deg):

-

180

-

Bending Precision (Deg):

-

adjustable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

zhuoran

-

Year:

-

2019

-

Power (kW):

-

4

-

Weight (KG):

-

800

-

Bend way:

-

Servo bend

-

Feed servo motor:

-

750w

-

Corner servo motor:

-

400w

-

left and right mold change servo motor:

-

400w

-

bend servo motor:

-

1.5kw

-

Pipe fittings allow elbows:

-

50

-

Number of parts that can be stored.:

-

500

-

Machine dimensions.:

-

2500*700*1300

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

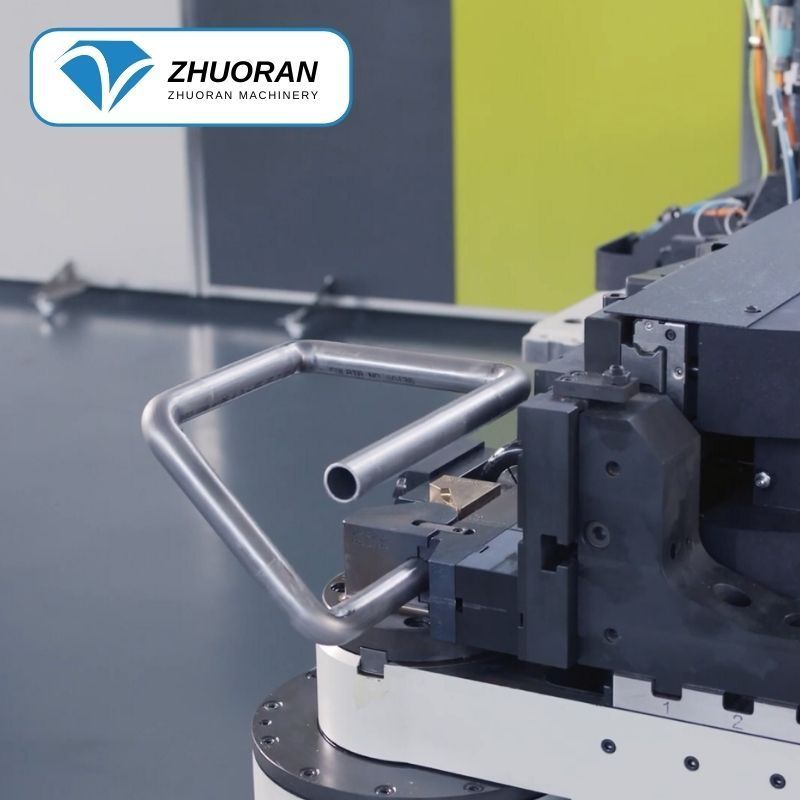

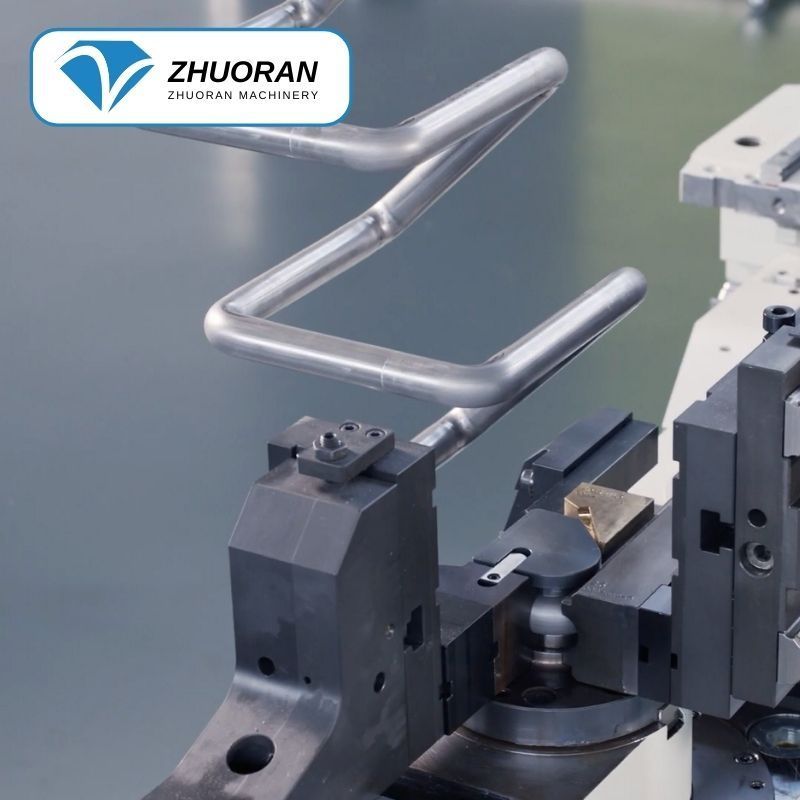

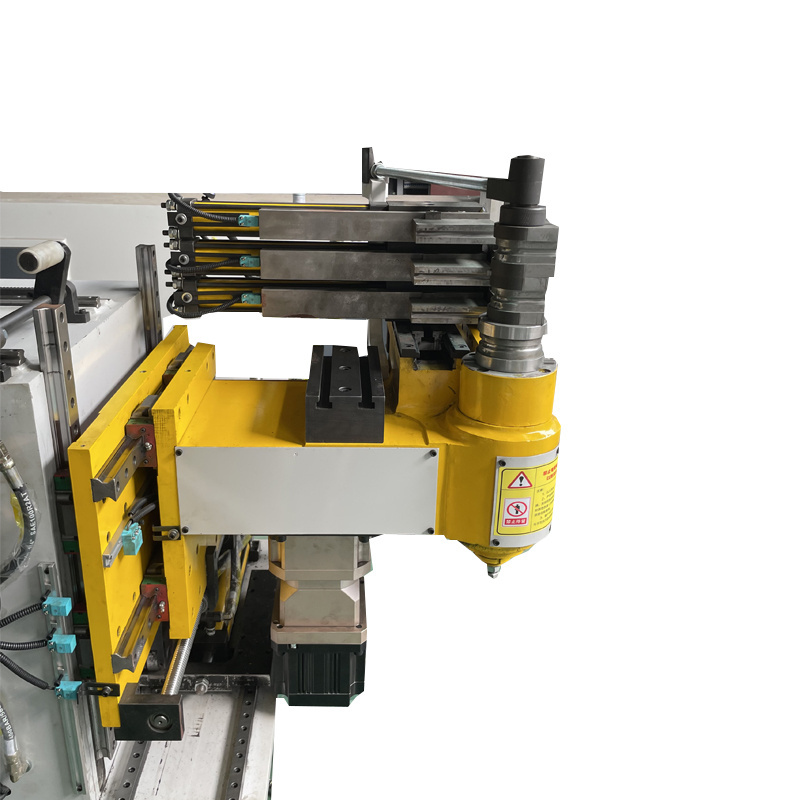

Hot Selling Hydraulic Aluminum Pipe Bending Machines CNC Stainless Steel Pipe Bending Machine

Video

|

Main specifications

|

The unit

|

DW75NC

|

|

Note:

1. The minimum bending radius is based on the pipe diameter 2. The maximum bending radius can be determined according to customer requirements 3. The maximum length of core penetration can be according to customer requirements |

||

|

Maximum bending diameter ×Wall thickness.

|

mm

|

Φ75×6

Carbon steel |

|

|

||

|

Maximum bending radius.

|

mm

|

R350

|

|

|

||

|

Minimum bending radius.

|

mm

|

R≥1.5D

|

|

|

||

|

Maximum bending Angle.

|

Degree

|

190

|

|

|

||

|

Standard core length.

|

mm

|

2800

|

|

|

||

|

Control system.

|

Microcomputer control

|

|

|

|

||

|

Number of elbow allowed for pipe fitting

|

Unit

|

|

16

|

|

||

|

Number of parts that can be stored.

|

Unit

|

|

16×16

|

|

||

|

Oil motor power.

|

KW

|

|

7.5

|

|

||

|

Maximum system pressure.

|

Mpa

|

|

12

|

|

||

|

Hydraulic system control.

|

|

|

Solenoid valve

|

|

||

|

Tank volume

|

L

|

|

250

|

|

||

|

Machine dimensions

|

mm

|

|

4300×900×1300

|

|

||

|

Machine weight

|

Kg

|

|

1900

|

|

||

2. Multiple layers of dies can be stacked to achieve different bend radii on one tube.

2 with slow bending, slow core pulling function.

1. Rebound compensation value setting procedure, procedure and processing data confidentiality function;

2. The operating system is equipped with passwords, keys, and records of quantity and duration, which is convenient for production management.

Recommend Products

Sample Display

Application Scenarios

Hot Searches