- Product Details

- {{item.text}}

Quick Details

-

Machinery Function:

-

Seasoning processing, Meat processing, Fruit and vegetable production, High temperature cooking, Syrup and honey treatment, Vacuum concentration, Melting of animal fat, Mix flour and knead

-

Application:

-

Food, sauces, fillings, meat puree, vegetable puree, bean paste, etc

-

Product name:

-

Mixing equipment for the kitchen

-

Model Number:

-

Capacity 100 liters ~3000 liters

-

Sterilizing way:

-

Steam indirect heating

-

Material:

-

Stainless Steel SUS304

-

Heating way:

-

Steam Boiler

-

Function:

-

Cooking, frying, stir-frying, steaming and so on.

-

Control system:

-

Fully automatic

-

Advantage:

-

High Efficiency

-

Processing Types:

-

Food, sauces, fillings, meat puree, vegetable puree, etc.

Quick Details

-

Weight (KG):

-

1200

-

Place of Origin:

-

Shandong, China

-

Machinery Capacity:

-

5~2500Kg/batch

-

Machinery Function:

-

Seasoning processing, Meat processing, Fruit and vegetable production, High temperature cooking, Syrup and honey treatment, Vacuum concentration, Melting of animal fat, Mix flour and knead

-

Application:

-

Food, sauces, fillings, meat puree, vegetable puree, bean paste, etc

-

Product name:

-

Mixing equipment for the kitchen

-

Model Number:

-

Capacity 100 liters ~3000 liters

-

Sterilizing way:

-

Steam indirect heating

-

Material:

-

Stainless Steel SUS304

-

Heating way:

-

Steam Boiler

-

Function:

-

Cooking, frying, stir-frying, steaming and so on.

-

Control system:

-

Fully automatic

-

Advantage:

-

High Efficiency

-

Processing Types:

-

Food, sauces, fillings, meat puree, vegetable puree, etc.

Product Description

It is used for food processing such as bean paste, fruit paste, jam and high viscosity materials such as traditional Chinese medicine and vacuum compression.

|

We accept equipment customization. You can provide drawings or dimension parameters for customization

|

|

|

|

|

||||

Main Features

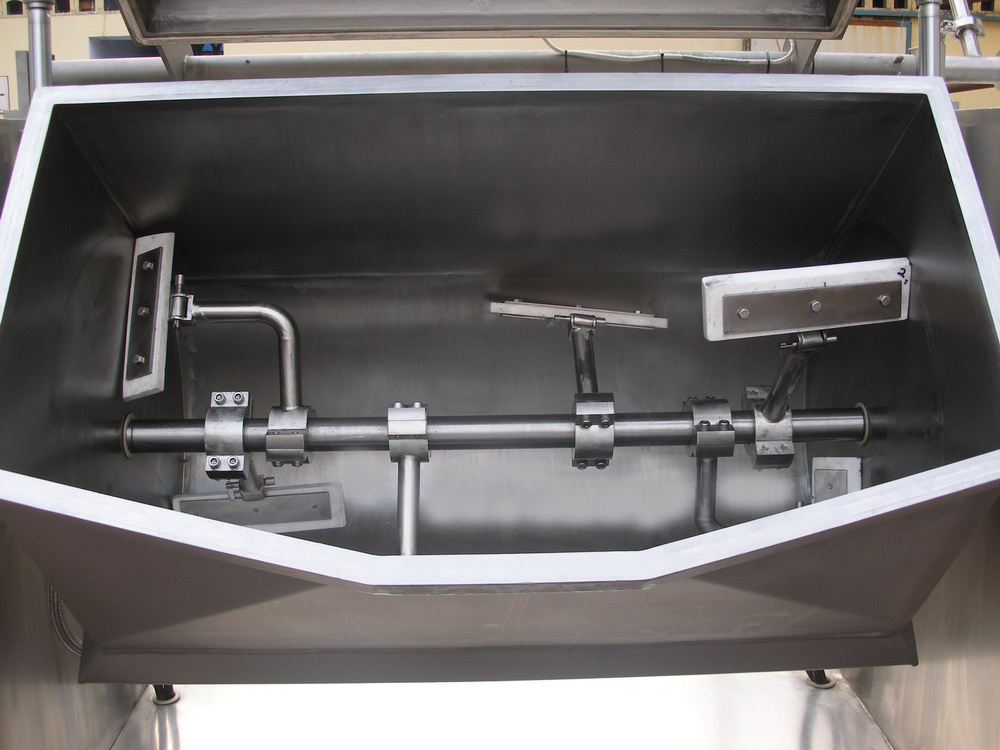

Native of u-shaped pot body top, vacuum jacketed adopts steam heating, no period of variable speed and the worm gear, the combination of the speed reducer drive, increases the transverse mixing torque, using ptfe material scraper agitator, in the process of material roll stirring, agitator and the pot body full contact, to ensure that without stirring blind Angle.The opening cover, unloading and reset of the pot body are controlled by hydraulic and mechanical transmission, which makes the operation very convenient.Vacuum fry can reduce fry temperature, especially suitable for heat sensitive raw materials fry, avoid excessive heat caused by color and taste deterioration, maintain the original color, aroma, taste of raw materials.It improves the fry efficiency, reduces the energy consumption and shortens the fry time.

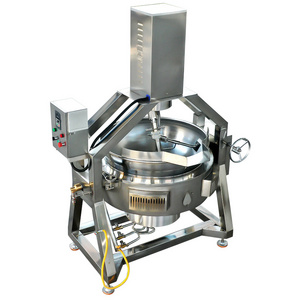

1. semi-closed or fully closed trough shape pot body, jacket using steam heating, heating area, high thermal efficiency.

2. stepless speed adjustment, the mixer and the pot body full contact scraping wall rolling material, so that the stirring full without dead Angle.

3. The transfer temperature of the material through platinum thermal resistance is displayed by the digital display thermometer, which makes the data intuitive.

4. The opening cover of the pot body is controlled by hydraulic mechanical transmission for unloading and resetting, which is easy to operate.

5. the use of advanced transmission and mechanical seal structure, so that the transmission parts and the pot is fully isolated, to ensure that the pot food clean and hygienic.

Certifications

The main parts

Durable, power, low noise, high efficiency, provides stirring, stirring, stirring, as well as pour out the pot and return power reducer.

High quality, strong power, high efficiency, durable, low noise, high energy efficiency, automatic opening cover, automatic closing cover hydraulic station device.

The fixed end is connected to the energy inlet and remains fixed at all times, and the other end is connected to the equipment housing joint with a universal rotary joint that can rotate 360 degrees.

The shell of the pot tilts the discharge and the return of the mechanism worm gear worm.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Transportation

Packaging Details

Under normal circumstances, we will use PE wrapping film for part of the product, then use wooden case packaging, or according to the special requirements of the customer packaging;If exported to European countries, we will fumigate the wooden cases.

Shipping Details

Under normal circumstances, we will use trucks to transport products to Qingdao port;Or according to customer requirements, choose the most convenient, the most economic mode of transportation.

Company profile

Zhongtai company is a leading supplier of food processing industry, beverage industry, edible mushroom processing industry and the pharmaceutical industry in sterilization equipment. The company has the national Pressure Vessel Design, Manufacture, Installation alteration service qualification, was awarded the "new high-tech enterprises," the title of Shandong province. Professional manufacture of various sterilization retort, medical sterilization equipment, jacketed kettle, agitation wok, pressure cooking pot, fermentation tank,extraction tank, concentration tank , mixing tank, animal oil and fat refining production line, rice dumpling production line, (sweet potato, potato) peeling production line, central kitchen equipment and other equipment,products have passed the European CE safety certification and ISO9001 international quality management system certification, with import and export rights. Forming a set of raw materials supply, product development, process design, production-manufacturing, finished product testing, storage and transportation, after-sales service in one of the network system.

Other major products and major engineering examples of the company

FAQ

1.How to visit our company?

You can fly to qingdao airport,our company is 1 and a half hour car driving away from qingdao,we can pick up you at qingdao city.

2.Installment, commission and others

The charges for installation and commissioning (if required by the buyer (user)) of these equipments are excluded. It will be charged at US$100 per person per day. Theround-trip air tickets between China and buyer's (user's) country, accommodation,insurance, food should be on the buyer's (user's)account.

3.Voltage:380V/50HZ or the voltage can be customized.

4. What if there is something wrong with the machine within one and half year?

We have two ways to solve this problem:

1)Phone call guidance to confirm the problem.

2)We will take video to show 'how to solve the problem'. All the problem can be solved by video guidance.

Hot Searches