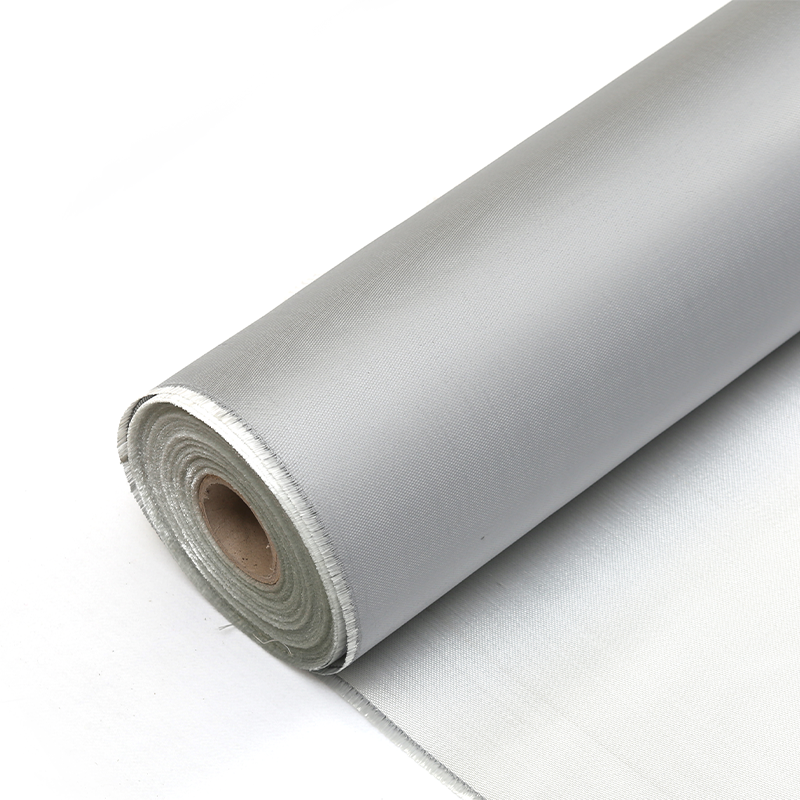

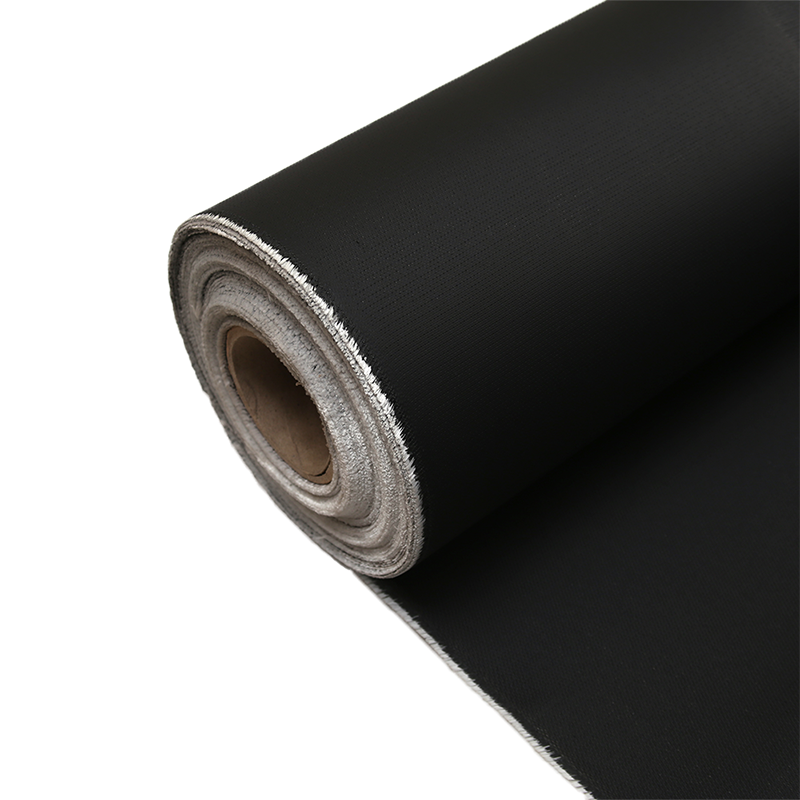

Silicone impregnated fiberglass fabric

uses specially formulated silicone rubber. After multiple impregnation processes on the base fabric, the silicone coating is perfectly combined with the

alkali-free E-glass fiberglass fabrics

, which have greater life and tensile strength.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LKTC - 00093

-

Weight:

-

according to the thickness

-

Width:

-

90CM-200CM, 1m/1.2m/1.5m /1.8m/2m/customized

-

Standing Temperature:

-

550 Degree

-

Product name:

-

Silicone Coated Fiberglass Fabric

-

Material:

-

silicone coating + fiberglass fabric

-

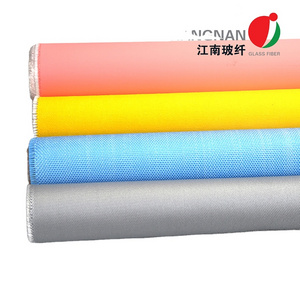

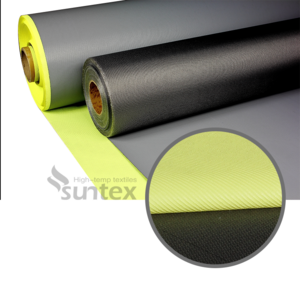

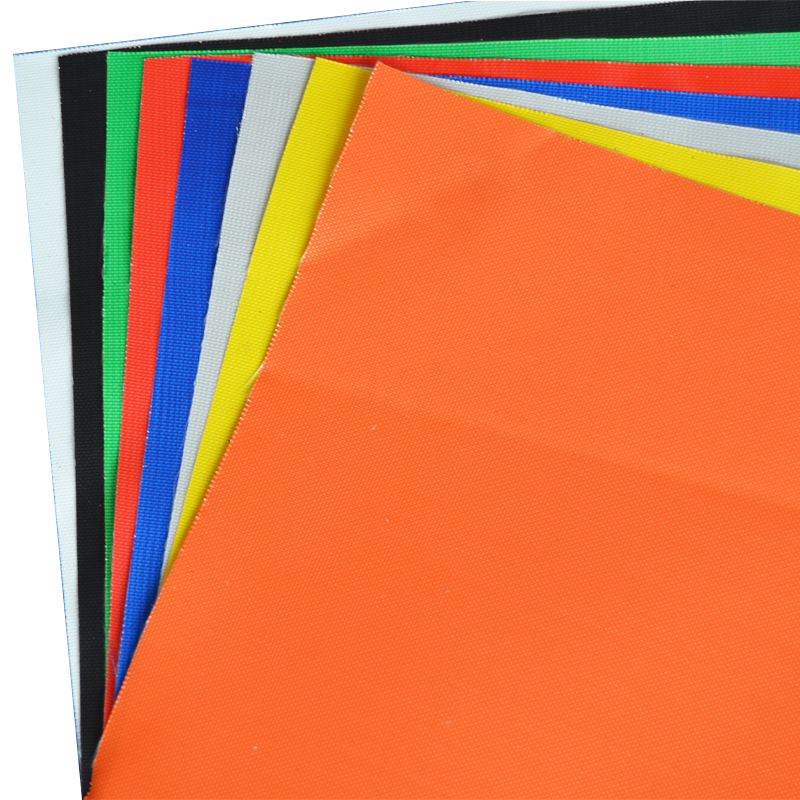

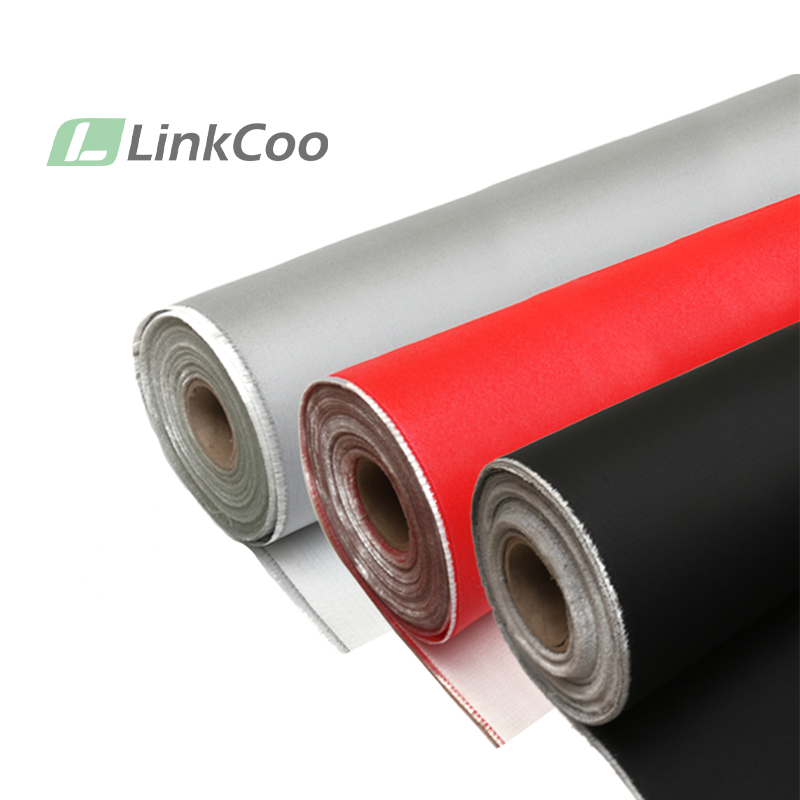

Color:

-

Yellow,Red,Black,Grey,custom made

-

Feature:

-

Heat Resistant Glass Fiber Fabric

-

Good Features:

-

High Temperature Reistance

-

Coating:

-

Silcone Coating

-

Thickness:

-

0.08mm-3mm

-

Roll Length:

-

50m

-

Application 1:

-

Thermal Insulation Cover

-

Application 2:

-

High Temperature Insulation Shield Fabric

Quick Details

-

Application:

-

Wall/Roof covering Cloth

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LinkCoo

-

Model Number:

-

LKTC - 00093

-

Weight:

-

according to the thickness

-

Width:

-

90CM-200CM, 1m/1.2m/1.5m /1.8m/2m/customized

-

Standing Temperature:

-

550 Degree

-

Product name:

-

Silicone Coated Fiberglass Fabric

-

Material:

-

silicone coating + fiberglass fabric

-

Color:

-

Yellow,Red,Black,Grey,custom made

-

Feature:

-

Heat Resistant Glass Fiber Fabric

-

Good Features:

-

High Temperature Reistance

-

Coating:

-

Silcone Coating

-

Thickness:

-

0.08mm-3mm

-

Roll Length:

-

50m

-

Application 1:

-

Thermal Insulation Cover

-

Application 2:

-

High Temperature Insulation Shield Fabric

Performance Parameters

|

|

Test Method

|

English

|

Metric

|

|

|

Temperature Resistance

|

ASTM-D-6413

|

Cold: -67 °F

Hot: Continuous 1000 hrs. +482 °F no change

|

Cold: -55 °C

Hot: Continuous 1000 hrs. 250 °C no change

|

|

|

Breaking Strength

|

ASTM-D-5034

|

|

|

|

|

Warp-

|

|

1500 lbs/inch

|

267.9 kg/cm

|

|

|

Fill-

|

|

2025 lbs/inch

|

200.95 kg/cm

|

|

|

Tear Strength

|

ASTM-D-1424

|

|

|

|

|

Elmendorf Tear

|

|

|

|

|

|

Warp-

|

|

200 lbs.

|

90.7 kg

|

|

|

Fill-

|

|

150 lbs.

|

68.05 kg

|

|

|

Flame Resistance

|

|

|

|

|

|

Afterglow

|

|

1 second max.

|

|

|

|

Flameout

|

|

1 second max.

|

|

|

Specification

|

Code

|

Unit Weight (g/m²)

|

Thickness (mm)

|

Coating

|

Color

|

Temperature

|

|

LKSGF-200-S-50

|

250

|

0.2

|

Double Coating

|

Grey, Black, Red and custom

|

250℃/482℉

|

|

LKSGF-430-S-50

|

480

|

0.45

|

Double Coating

|

|

|

|

LKSGF-430-D-80

|

510

|

0.48

|

Single Coating

|

|

|

|

LKSGF-430-S-130

|

560

|

0.52

|

Double Coating

|

|

|

|

LKSGF-430-S-160

|

590

|

0.55

|

Double Coating

|

|

|

|

LKSGF-660-D-120

|

780

|

0.7

|

Single Coating

|

|

|

|

LKSGF-660-S-200

|

860

|

0.8

|

Double Coating

|

|

|

|

LKSGF-850-S-200

|

1050

|

0.92

|

Double Coating

|

|

|

|

LKSGF-1250-S-300

|

1550

|

1.35

|

Double Coating

|

|

|

Products Description

LinkCoo silicone coated fiberglass fabric, using

E-Glass fiberglass fabrics

, one or both sides with silicone rubber coating, resistant to high temperature. The fiberglass base fabric provides it with mechanical strength. Silicone coating protects sparks and metal splashes generated by welding, making the entire fabric impenetrable to any liquid, gas, smoke, or light. Its flame retardant and heat resistant properties are permanent and can withstand temperatures of

250℃ in continuous and 550℃ in peak operation

.

Silicone coated fiberglass cloth is a versatile fabric used as a flame retardant hood, smoke curtain, or welding blanket. The silicone side increases the stability of the material for easy handling and cutting without tearing or unraveling the thread. Coated fiberglass fabric is more wear-resistant than uncoated fiberglass fabric and also offers a good balance between quality-performance-price.

Fire Test

Silicone fabrics are widely used for heat protection and spark protection of objects, surfaces, and areas. Heaterk recommends vertical use, such as curtains; try always to place the silicone side on the exposed site. The flexibility of this fabric can be perfectly adapted to any surface that needs protection, such as metal structures, boiler manufacturing installations, pipes, removable insulation jackets, etc.

Features

The flame retardant performance is excellent. Under multiple tests, the flame is extinguished within 1s, the flame retardant

performance will not change over time, and it is permanently available.

performance will not change over time, and it is permanently available.

Temperature range 250℃ continuous and 550℃ peak.

Completely proof against sparks and metal splashes, impermeable to liquids and fumes. Soft fabric for easy handling and no tearingwhen cutting.

According to the different industries used, the thickness of silicone fabric can be customized from 0.3mm-5mm, andthe conventional width is 5-1500mm.

Suitable for indoor and outdoor use, it is light-tight and ideal for protecting

light-sensitive elements. Resistant to water and oil

Application

Application

* Fire-retardant fabrics used to make spark-proof fabrics

* Flexible flame retardant industrial barrier.

* Protective curtains for welding.

* Welding blanket.

* Thermal barrier used to protect components.

* Suitable for the production of thermal protectors.

* Removable pads flange and valve covers

* Smoke and flame retardant

Industry

* Various heavy industry fields including spot welding, arc welding, MIG, cutting.

* Oxygen cutting and plasma cutting.

* military

* Construction industry.

* Metal foundry industry.

* Fire-retardant fabrics used to make spark-proof fabrics

* Flexible flame retardant industrial barrier.

* Protective curtains for welding.

* Welding blanket.

* Thermal barrier used to protect components.

* Suitable for the production of thermal protectors.

* Removable pads flange and valve covers

* Smoke and flame retardant

Industry

* Various heavy industry fields including spot welding, arc welding, MIG, cutting.

* Oxygen cutting and plasma cutting.

* military

* Construction industry.

* Metal foundry industry.

Certifications

LinkCoo silicone rubber fabrics were certified in 2020 by the UL 94 test (Standard for plastics flammability) with a V0 classification. In 2021, this fabric also participated in ASTM E84 (Standard Test Method for Surface Burning Behavior of Building Materials) with a Class A classification. It also complies with Class 1 classification according to EN ISO 9185 - Behavior of materials under the influence of small molten metal splashes.

Hot Searches