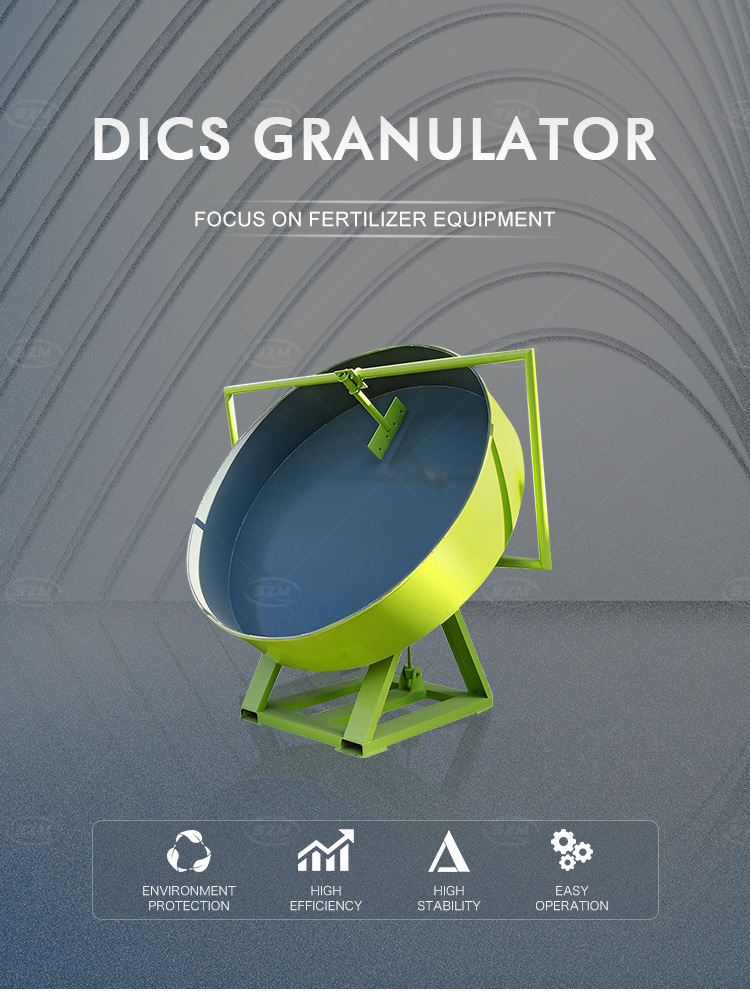

Working principle of

disc granulator

Various dry powder materials are added from the top of the equipment, degassed, spirally pre-compressed and transported to the arc-shaped notches of the two rollers. The two rollers rotate at the same speed and in opposite directions to bite the materials into the tank and perform forced compression. After passing through the compression zone, the pressure is gradually reduced, and its surface tension and gravity make it naturally escape, enter the crusher and sizing machine for crushing and trimming, and then enter the vibrating screen for screening, and the qualified products are sent to the finished product through the conveyor Warehouse or direct packaging.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

1200*950*1300 mm

-

Weight (KG):

-

210

-

Power (kW):

-

1.5

-

Product name:

-

Organic Fertilizer Disc Rapid Mixer Dry Granulator Pellet Machine

-

Name:

-

Disc Granulator

-

Function:

-

Produce Organic Fertilizer Pellet

-

Color:

-

Customers' Demand

-

Model:

-

SZ-800

-

Motor:

-

11KW

-

Advantage:

-

Energy Saving Consumption

-

Working method:

-

Wet Process

-

Application:

-

Fertilizer Pellet Making Machine

Quick Details

-

Output (kg/h):

-

300

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

shunzhi

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

1200*950*1300 mm

-

Weight (KG):

-

210

-

Power (kW):

-

1.5

-

Product name:

-

Organic Fertilizer Disc Rapid Mixer Dry Granulator Pellet Machine

-

Name:

-

Disc Granulator

-

Function:

-

Produce Organic Fertilizer Pellet

-

Color:

-

Customers' Demand

-

Model:

-

SZ-800

-

Motor:

-

11KW

-

Advantage:

-

Energy Saving Consumption

-

Working method:

-

Wet Process

-

Application:

-

Fertilizer Pellet Making Machine

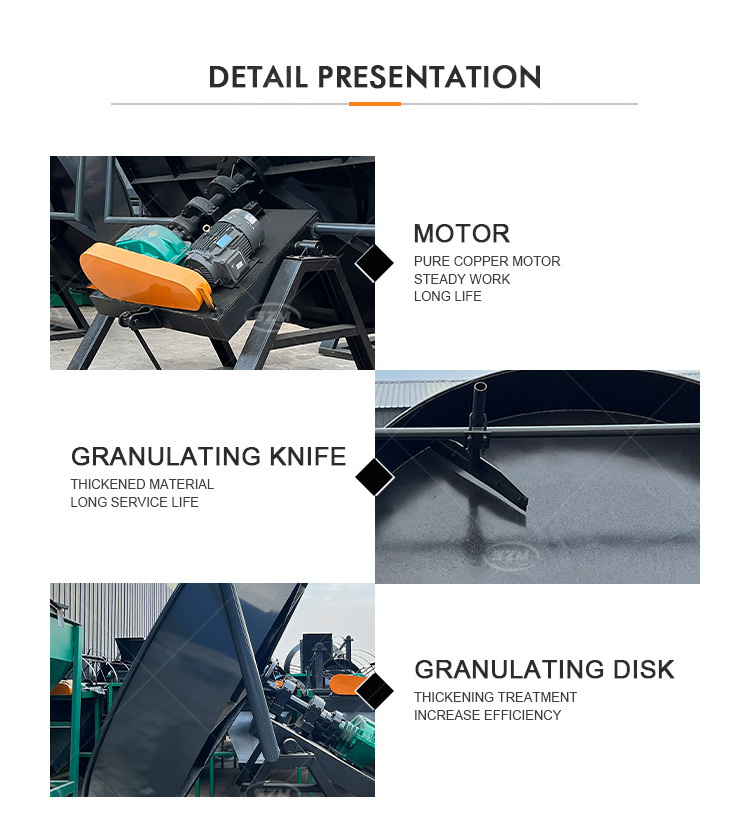

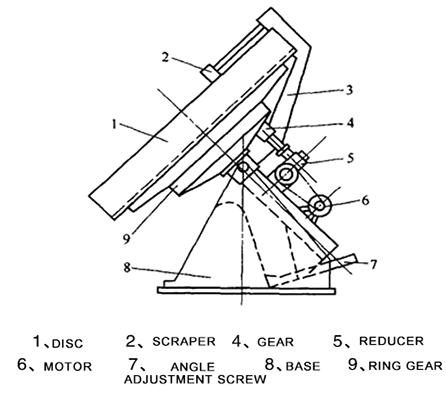

Disc Granulator

The disc granulator is composed of a large plate, a large gear, a transmission part, a frame, a base, a scraper rack, and an unpowered scraper.

① The main body of the disc granulator, the main body includes the structure of the frame, the adjustment part and the granulation disc;

②One main reducer, the input shaft is equipped with a pulley, and the output shaft is equipped with a pinion;

③One main point motor with one pulley;

④ Supporting pelletizing disc device, including one main shaft, two roller bearings, and two bearing seats;

Disc Granulator

The disc granulator is suitable for conveying various non-sticky materials in powder, material or small blocks, such as organic fertilizer, livestock manure, coal powder, cement, clinker, limestone, shale, coal gangue, clay, etc. It can be widely used in gold dressing plants, coal mining plants, chemicals, infrastructure and mechanized foundries, etc., as equipment for continuous, uniform and quantitative feeding and batching.

|

Model

|

Diameter of Disc

(mm)

|

Edge Height

(mm)

|

Rotary Speed

(r/min)

|

Motor Power

(kw)

|

Capacity

(t/h)

|

Model of Reducer

|

Overall Size(mm)

|

|

SZ-500

|

500

|

200

|

32

|

0.55

|

0.02-0.05

|

BWY0-43-0.55

|

650*600*800

|

|

SZ-600

|

600

|

280

|

33.5

|

0.75

|

0.05-0.1

|

BWY0-43-0.55

|

800*700*950

|

|

SZ-800

|

800

|

200

|

21

|

1.5

|

0.1-0.2

|

XWD4-71-1.5

|

900*1000*1100

|

|

SZ-1000

|

1000

|

250

|

21

|

1.5

|

0.2-0.3

|

XWD4-71-1.5

|

1200*950*1300

|

|

SZ-1200

|

1200

|

250

|

21

|

1.5

|

0.3-0.5

|

XWD4-71-1.5

|

1200*1470*1700

|

|

SZ-1500

|

1500

|

300

|

21

|

3

|

0.5-0.8

|

XWD5-71-3

|

1760*1500*1950

|

|

SZ-1800

|

1800

|

300

|

21

|

3

|

0.8-1.2

|

XWD5-71-3

|

2060*1700*2130

|

|

SZ-2000

|

2000

|

350

|

21

|

4

|

1.2-1.5

|

XWD5-71-4

|

2260*1650*2250

|

|

SZ-2500

|

2500

|

450

|

14

|

7.5

|

1.5-2.0

|

ZQ350

|

2900*2000*2750

|

|

SZ-2800

|

2800

|

450

|

14

|

11

|

2-3

|

ZQ350

|

3200*2200*3000

|

|

SZ-3000

|

3000

|

450

|

14

|

11

|

2-4

|

ZQ350

|

3400*2400*3100

|

|

SZ-3600

|

3600

|

450

|

13

|

18.5

|

4-6

|

ZQ400

|

4100*2900*3800

|

Pre-sale Service:

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician;

5.Free CAD design: if you can provide the material, your aim capacity and your factory information, we can make a free CAD design for you.

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipment;

4.Dispatching engineers to install and debug equipment;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems Providing life-long maintenance service

7.Providing technical exchanging.s.

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

4.Training periodically high qualified service technician;

5.Free CAD design: if you can provide the material, your aim capacity and your factory information, we can make a free CAD design for you.

After-sales Service:

1.Highly inspecting equipment in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients for foundation construction of equipment;

4.Dispatching engineers to install and debug equipment;

5.Training the first-line operators on site;

6.Regularly visit clients to solve production problems Providing life-long maintenance service

7.Providing technical exchanging.s.

Q1. Are you factory or trade company?

A1. We are manufacturer, we also supply trade service.

Q2. What about your price?

A2. We always supply the products with low price, because we believe this is the way to build long-term business and earn good reputation.Our price is 3%-5% lower than the average market price.

Q3. What payment terms do you accept?

A3. Welcome clients to place orders by Alibaba Trade Assurance! Other payment ways such as T/T, L/C, D/P, etc can be negotiated.

Q4. How about your delivery time?

A4: Generally, it will take 15-20 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5: what will you do if the machine is broken down?

A5: The Products warranty is one year. We will provide the technical advice and find the solution immediately for you when the machine is in trouble. For those wear parts, we guarantee the high quality parts for long-term supply.

Q6: How do you make our business long-term and good relationship?

A6: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches