Introduction

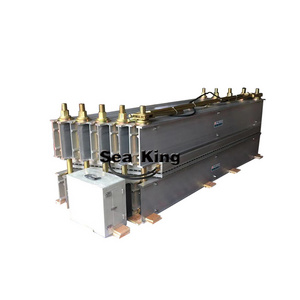

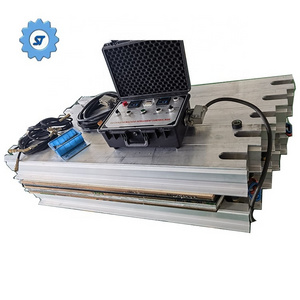

C type vulcanizing press,It is mainly used for vulcanizing all kinds of rubber and plastic

model

products and non-model products.Mainly used in producing

caterpillar band,rubber conveyor belt jointing,door and window rubber seal strip,etc.

Fetures:

1.PLC control & touch screen

2.Auto mold closing, air exhaust, temperature control, timing setting

3.Custom mold push out system

4.Well-sealed hydraulic cylinder with precise grinding and finishing

5.Stable hydraulic pressure station