- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SOC600

-

Place of Origin:

-

Zhejiang, China

-

Crushable Materials:

-

Paper,books,plastic,wood,textile

-

Shredder construction:

-

two shaft shredder

-

Blade construction:

-

low speed rotating blade

-

Hydraulic system:

-

With hydraulic pushing system

-

Shredding Particles:

-

20mm * random

-

Throughout per hour:

-

300-800 kg per hour

-

Feeding width:

-

1000 * 600 mm

-

Power/ Voltage:

-

22KW / 380V/ 50HZ

-

Machine Weight:

-

1350 KGS

-

Machine size:

-

L2300 x W1360 x H2280mm

Quick Details

-

Power:

-

Electricity

-

Size:

-

Normal

-

Brand Name:

-

SUPU

-

Model Number:

-

SOC600

-

Place of Origin:

-

Zhejiang, China

-

Crushable Materials:

-

Paper,books,plastic,wood,textile

-

Shredder construction:

-

two shaft shredder

-

Blade construction:

-

low speed rotating blade

-

Hydraulic system:

-

With hydraulic pushing system

-

Shredding Particles:

-

20mm * random

-

Throughout per hour:

-

300-800 kg per hour

-

Feeding width:

-

1000 * 600 mm

-

Power/ Voltage:

-

22KW / 380V/ 50HZ

-

Machine Weight:

-

1350 KGS

-

Machine size:

-

L2300 x W1360 x H2280mm

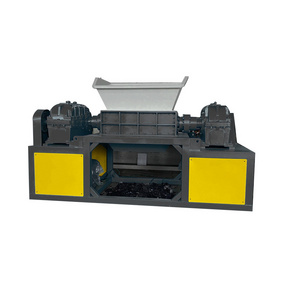

Product Description

Paper Document Shredding Machine

SUPU SPT600 High Efficiency heavy duty multiple purpose two shaft shredder, suitable for waste

Paper, Document, Books, Banknotes, paper roll, plastic drum, plastic bottle, plastic film, wooden material,E-waste, metal scarp shredding and recycling purpose, final particle by customized size for 20mm-1100mm with 500 kg/hr - 1200 kg/hr working capacity,SPT600 contain strong machine construction, low speed high torque shredding system with high level blade, strong motor and reducer to support the high efficiency shredding powder and smart control PLC system to protect the safety and reliable shredderoperation.

Specification

|

Crushable Materials

|

Paper, books, plastic, wood, textile,Meal scarp,tire,E-waste

|

|

Shredder construction

|

two shaft shredder

|

|

Blade construction

|

Low speed high torque rotating blade

|

|

Blade thickness

|

20mm or customized

|

|

Shredding Particles

|

20mm * random

|

|

Throughout per hour

|

300-800 kg per hour

|

|

Feeding width

|

1000 * 600 mm

|

|

Power/ Voltage

|

22-30KW / 380V/ 50HZ

|

|

Machine Weight

|

1350 KGS

|

|

Machine size

|

L2300 x W1360 x H2280mm

|

Shredding Effect

Application

1. Plastic: plastic block, plastic sheets, PET bottle, plastics pipe, plastic container, plastic drum

2. Wood: Wood pallet, wooden box, timber residues

3. Paper Product: Waste paper,packing paper, cardboard paper and confidential documents

4. E waste: circuit board,FPC,electronic component

5. Mixed Waste: MSW(municipal solid waste) and RDF (refuse-dervied fuel) production

6. Textile: cloth fiber, nylon;

7. Cable wires: copper core cable, aluminum cable, composite cables;

8. Polypropylene pipe, industrial packaging & plastic films, PP woven bags;

2. Wood: Wood pallet, wooden box, timber residues

3. Paper Product: Waste paper,packing paper, cardboard paper and confidential documents

4. E waste: circuit board,FPC,electronic component

5. Mixed Waste: MSW(municipal solid waste) and RDF (refuse-dervied fuel) production

6. Textile: cloth fiber, nylon;

7. Cable wires: copper core cable, aluminum cable, composite cables;

8. Polypropylene pipe, industrial packaging & plastic films, PP woven bags;

Product Advantages

1. The shredder single shaft for plastic can shred various bulk materials, basket materials, pipe, plate, sheet, big roll film, which are difficult to be shredded by single shaft shredder.

2. The frame is combinational structures, made from precision machined extra-thick sheet, slewing axis is forced, Lange-angle, hexagonal prism, the hopper is large-caliber, and substantial, so good-sized material is practicable.

3. Revolving balde is designed and processed particular in thickness, shape, arrange orderand so on.The blade is made from special alloy steel, sturdy and durable.

4. PLC control system, forward and reverse operate and stop automatically can protect the machine when the materials is too big and much. Operate safely, low speed running, low noise, little dust.

5. With strong hydraulic cylinder pushing system to make the material reach the rotating,improved the shredding effect.

2. The frame is combinational structures, made from precision machined extra-thick sheet, slewing axis is forced, Lange-angle, hexagonal prism, the hopper is large-caliber, and substantial, so good-sized material is practicable.

3. Revolving balde is designed and processed particular in thickness, shape, arrange orderand so on.The blade is made from special alloy steel, sturdy and durable.

4. PLC control system, forward and reverse operate and stop automatically can protect the machine when the materials is too big and much. Operate safely, low speed running, low noise, little dust.

5. With strong hydraulic cylinder pushing system to make the material reach the rotating,improved the shredding effect.

Hot Searches