The process of tempering involves heating the glass to a temperature of around 620°C (1,148°F) and then cooling it rapidly with a blast of cold air. This causes the glass to contract and become much stronger and more resistant to impacts.

Flat tempered glass is commonly used in a variety of applications, including windows, doors, shower enclosures, table tops, and more. It is also used in the automotive industry for car windows and windshields.

Flat tempered glass is commonly used in a variety of applications, including windows, doors, shower enclosures, table tops, and more. It is also used in the automotive industry for car windows and windshields.

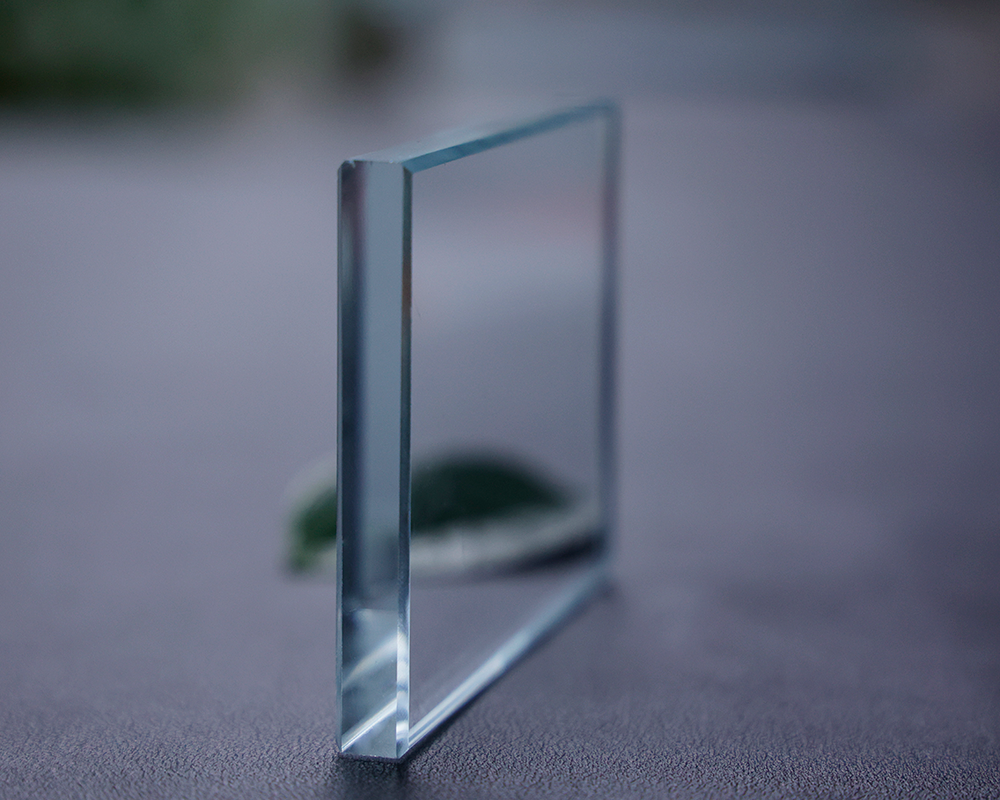

Tempered glass is often preferred over regular glass because it is less likely to break and, if it does break, it shatters into small, rounded pieces rather than sharp shards, which reduces the risk of injury. Flat tempered glass is available in a range of thicknesses and can be cut to size to fit specific applications. It can also be treated with various coatings and finishes to enhance its performance and appearance.

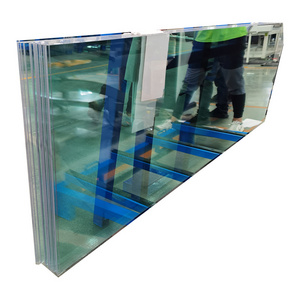

Max Size: 3300mm* 6500mm; 2800* 13000mm

Min Size: 300mm* 200mm

Glass Thickness: 3mm- 25mm

Glass Color: clear, ultra clear, F green, Ford blue, gray, Light Bronze, Deep Bronze, etc

Min Size: 300mm* 200mm

Glass Thickness: 3mm- 25mm

Glass Color: clear, ultra clear, F green, Ford blue, gray, Light Bronze, Deep Bronze, etc

Packing: Customize fumigation-free sealed wooden boxes according to your quantity and size, and take specific inner packaging protection measures to ensure safety during various transportation.