The automatic tool change function instantly increases the efficiency of the machine about 1.5 times.

- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

3000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

9

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AccTek

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5520*2950*1990mm

-

Power (kW):

-

13

-

Weight (KG):

-

2000

-

Working area:

-

2000x3000x250mm

-

Spindle:

-

9.0kw HQD air cooling atc spindle

-

X Y axis transmission:

-

Gear and rack transmission

-

Z axis transmission:

-

Taiwan TBI ball screw transmission

-

Rails:

-

Taiwan HIWIN 25 rails

-

Controller:

-

Mach3 controller

-

Table:

-

Vacuum table

-

Motor:

-

Leadshine easy servo motor

-

Driver:

-

Leadshine driver

-

Inverter:

-

Delta inverter

Quick Details

-

Working Table Size(mm):

-

2000×3000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 18000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

3000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

9

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AccTek

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5520*2950*1990mm

-

Power (kW):

-

13

-

Weight (KG):

-

2000

-

Working area:

-

2000x3000x250mm

-

Spindle:

-

9.0kw HQD air cooling atc spindle

-

X Y axis transmission:

-

Gear and rack transmission

-

Z axis transmission:

-

Taiwan TBI ball screw transmission

-

Rails:

-

Taiwan HIWIN 25 rails

-

Controller:

-

Mach3 controller

-

Table:

-

Vacuum table

-

Motor:

-

Leadshine easy servo motor

-

Driver:

-

Leadshine driver

-

Inverter:

-

Delta inverter

Product Description

1325 atc cnc router 1530 2030 2130 3d wood cutting machine woodworking machinery with linear or carousel tool changer

Automatic tool changer (ATC) CNC Router machine is suitable for the processing of various complex products or a variety of processing. It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

Technical parameters

|

X,Y Working Area

|

2000*3000*250mm

|

|

Resolution

|

0.01mm

|

|

Lathe Structure

|

Seamless welded steel structure, better than cast iron one

|

|

X,Y Structure

|

Rack and pinion, gear drive,

Taiwan 25mm square guide rails |

|

Z Structure

|

Taiwan TBI ball screw,

Taiwan 25mm square guide rails |

|

Max. Idling Speed

|

40m/min

|

|

Spindle

|

9.0kw

Air-cooling atc spindle

|

|

Working Voltage

|

AC220V,1PH or 220V/380V,3PH, 50/60Hz

|

|

Motor and driver

|

servo motor and drivers

|

|

Command

|

G code (HPGL,U00,mmg,plt)

|

|

Operating System

|

Mach3

|

|

Diameter of Cutter

|

φ3.175-φ12.7

|

|

Work Holding

|

Vacuum with t slot

|

|

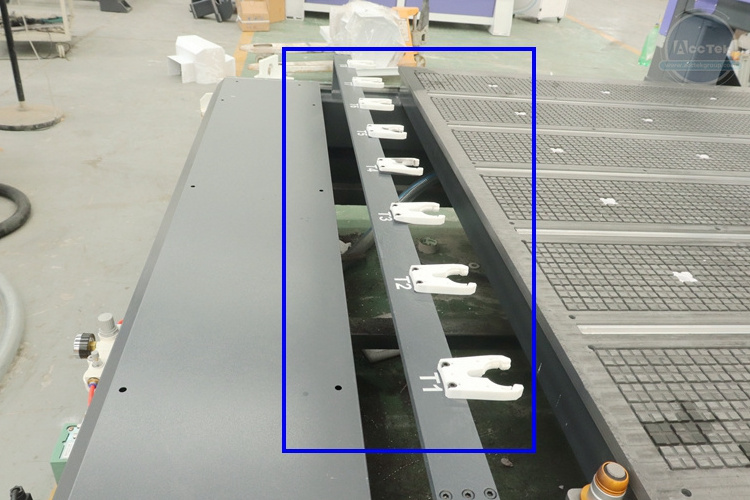

Tool Magazine

|

8-slot Tool Magazine with 8 ISO 30 tools

|

Machine Details

Auto tool magazine

It can process saving, reduce human error and increase efficiency.

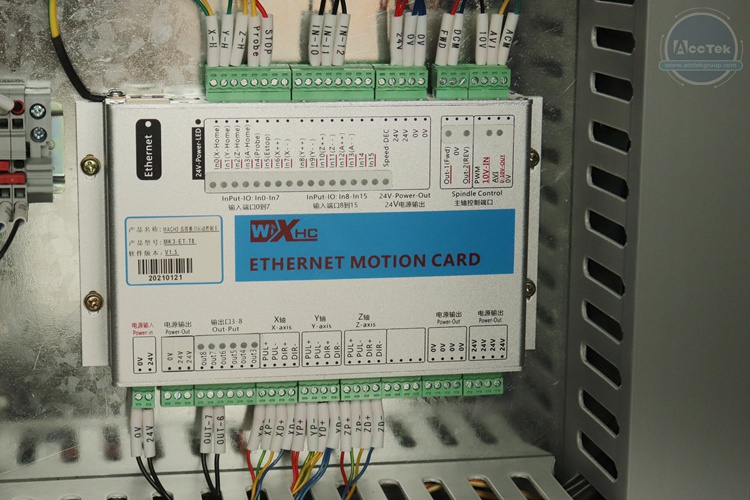

Mach3 controller

Multiple system control, no driv required and Network.

Greatly reduce the use of requirements, direct computer control.

Leadshine driver

It is used with a Leadshine easy servo motor.

Faster speed with signal feedback .Low heat radiation .Run smoothly at ultra-low speed.

Reduce the vibration ,avoid oscillation . Efficient torque enhancement .

Auto oil lubrication

Oil and lubricate the machine regularly to extend the life of the machine

optional:

optional 1: atc cnc wood machine with spindle swing

optional 2 : atc cnc wood machine with rotary device

optional 3 : atc cnc wood machine with lift tools etc

For specific optional accessories, please contact us and communicate with us

Sample & Application

♦ It mainly used for woodworking industry, door, cabinets, kitchen utensils, chairs, decoration business, mould industry,wood panel,wave board processing, MDF sheet carving, screen, calligraphy tablet design , relief, wood furniture, computer tables, panelfurniture, office furniture,instrument industry, and so on.

♦ It can also for advertising signs, acrylic brands, 3D characters, garden or wall decoration, logo, forming system

module,billboard, plate, LED/neon channel, literal-hole cut, blister Light box mold.

♦ It can also for advertising signs, acrylic brands, 3D characters, garden or wall decoration, logo, forming system

module,billboard, plate, LED/neon channel, literal-hole cut, blister Light box mold.

metal adornment art

metal adornment art

Payment&Shipping

About the delivery.

Its need about 15-20 working days to produce the machine after get your deposit. all thing is tested well,then we arrange the delivery.

Its need about 15-20 working days to produce the machine after get your deposit. all thing is tested well,then we arrange the delivery.

About payment:

We accept T/T , you can pay 30% in advance, 70% before delivery.

The machine will be produced after received your deposit.after the machine is ready, we will show you the machine photos and the testing video.

After you agree, please finish the balance.Finally.we arrange the delivery.

We accept T/T , you can pay 30% in advance, 70% before delivery.

The machine will be produced after received your deposit.after the machine is ready, we will show you the machine photos and the testing video.

After you agree, please finish the balance.Finally.we arrange the delivery.

Our advantage

1.Guarantee: 3 years guarantee of the whole machine+1.5 years warranty spindle and motor

2.Software issue: We will support technical support of lifetime free.

3.Hardware issue: Main parts(excluding the consumables) shall be replaced/

repaired free of charge if there is any problem during the warranty period.

4.Support online: our engineer give 1 hours to solve question.

5.Training in AccTek factory: We are able to train your staff after placed order in our factory for free.

6.Oversea service: We are able to send technician to your workshop to do the installation and training.

You will need bear the related costs. (flight,visa,hotel,training costs, etc.)

2.Software issue: We will support technical support of lifetime free.

3.Hardware issue: Main parts(excluding the consumables) shall be replaced/

repaired free of charge if there is any problem during the warranty period.

4.Support online: our engineer give 1 hours to solve question.

5.Training in AccTek factory: We are able to train your staff after placed order in our factory for free.

6.Oversea service: We are able to send technician to your workshop to do the installation and training.

You will need bear the related costs. (flight,visa,hotel,training costs, etc.)

We have passed the international certifications such as CE certification, ISO9001 quality management system certification, Alibaba enterprise certification and design patents.

Strictly control all aspects of incoming materials, processing, assembly, commissioning, testing, packaging and shipping to ensure the performance and quality of laser products.

Strictly control all aspects of incoming materials, processing, assembly, commissioning, testing, packaging and shipping to ensure the performance and quality of laser products.

Company Info

Customer feedback

FAQ:

Q: How to install and maintain the machine?

A: Before you use it, we will send the operation tutorial and installation operation video with an English version to you. If you still can not operate, we will provide video guidance online.

Q: What are the machine working environment requirements?

A: The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust,static electricity, humidity, and chips to cause parts failure.

Q: How many days do the goods ready to ship?

A: The specific delivery date needs to be communicated with the sales. If we have stock, it can be shipped within five days. If it is not in stock, it will take 15 to 20 days to prepare goods. By the way, Most of the machines are in stock.

Q: What is the mode of transportation of the products?

A: The specific transportation method can be selected according to the needs, like by sea, by air, or by train. Our trade terms are mostly centered on FOB, but we offer EXW, CIF, depending on which is more convenient for you.

Q: What are the machine working environment requirements?

A: The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust,static electricity, humidity, and chips to cause parts failure.

Q: How many days do the goods ready to ship?

A: The specific delivery date needs to be communicated with the sales. If we have stock, it can be shipped within five days. If it is not in stock, it will take 15 to 20 days to prepare goods. By the way, Most of the machines are in stock.

Q: What is the mode of transportation of the products?

A: The specific transportation method can be selected according to the needs, like by sea, by air, or by train. Our trade terms are mostly centered on FOB, but we offer EXW, CIF, depending on which is more convenient for you.

Hot Searches