movable jaw approaches and leaves the fixed jaw cyclical, which makes the materials squeezed, rubbed, multi-roller crusher, etc. so that the materials are crushed into small size, and then decline gradually, at last discharge from the discharging mouth.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fuyuan

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

2000 KG

-

Marketing Type:

-

New Product

-

Product name:

-

Mobile Jaw Crusher

-

Keyword:

-

Fine Stone Crusher

-

The Machines classification:

-

Building Stone Production Line

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Function:

-

Mining Crusher Equipment

-

Raw material:

-

Stones Rocks Ores

-

Usage:

-

Crushing Work

-

Applicaton:

-

Stone Process

-

Color:

-

Customer Requirement

-

Processed Materials:

-

Rock Ore

Quick Details

-

Application:

-

Quarry

-

Capacity(t/h):

-

5-220t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuyuan

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

2000 KG

-

Marketing Type:

-

New Product

-

Product name:

-

Mobile Jaw Crusher

-

Keyword:

-

Fine Stone Crusher

-

The Machines classification:

-

Building Stone Production Line

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Function:

-

Mining Crusher Equipment

-

Raw material:

-

Stones Rocks Ores

-

Usage:

-

Crushing Work

-

Applicaton:

-

Stone Process

-

Color:

-

Customer Requirement

-

Processed Materials:

-

Rock Ore

PE400 * 600 jaw crusher with vibrating screen and feeding

Jaw crusher is combined with the secondary crushing equipment in the whole stone crushing line,like cone crusher and impact crusher. Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications. Now it is widely applied in mining, metallurgy,quarry, building waste, smelting,electricity, building material, highway, railway, water conservancy, transportation, chemical industries and other fields.

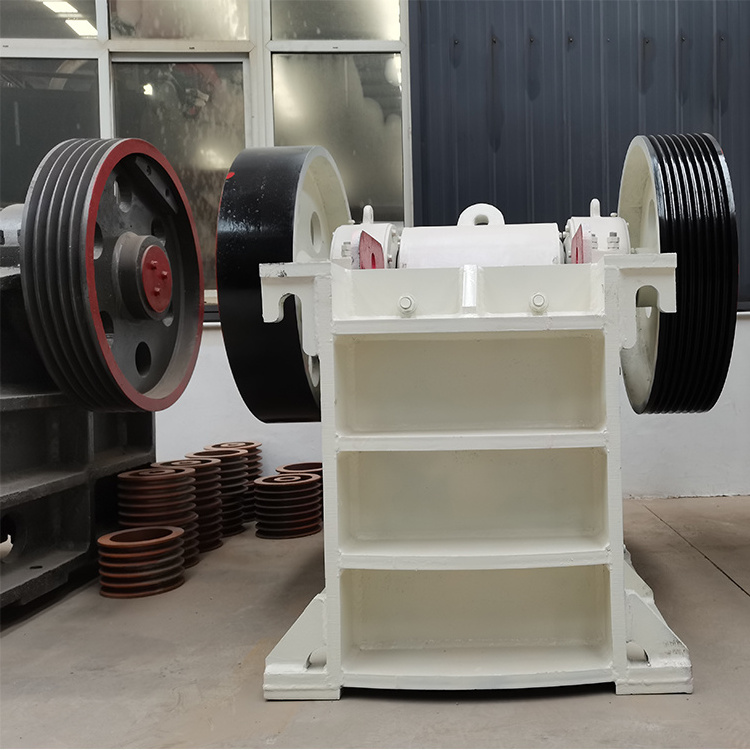

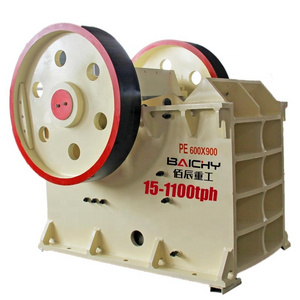

Product Display

There are many models of PE jaw crushers, among which the most popular models are PE-400*600, PE-250*400, PE-500*750, etc.

Application

: It is used for primary crushing (coarse crushing) and medium crushing of materials.

Feed size

:

100 mm-500 mm

for relatively larger stones.

Output size

:

10 mm-100 mm

, the discharge port has a wide adjustment range.

Main Technical Paraments

|

Model

|

Opening size(mm)

|

Max feeding size(mm)

|

Output adjustment range(mm)

|

Production capacit(t/h)

|

|

PE200*350

|

200*350

|

180

|

18-70

|

3-10

|

|

PE250*400

|

250*400

|

200

|

20-50

|

5-20

|

|

PE400*600

|

400*600

|

350

|

40-100

|

15-60

|

|

PE500*700

|

500*700

|

425

|

50-100

|

40-110

|

|

PE600*900

|

600*900

|

480

|

65-160

|

90-180

|

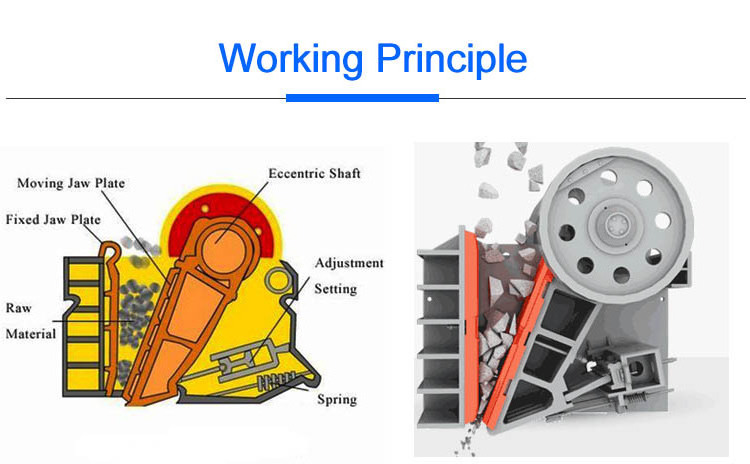

Working Principle

Woking Principle

Working principle of stone jaw crusher motor drives the eccentric axis rotating through the belt pulley, so that the

Jaw crusher features:

1. The jaw crusher cavity is deep and there is no dead zone, which improves the feeding capacity and output;

2. The crushing ratio is large and the product size is uniform;

3. Gasket-type discharge opening adjustment device is reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment;

4. The lubrication system is safe and reliable, the replacement of parts is convenient, and the maintenance workload is small;

5. Simple structure, reliable work, low operating cost;

6. Equipment energy saving: single machine energy saving 15%~30%;

7. The adjustment range of the discharge opening is large, which can meet the requirements of different users;

8. Low noise

Application Field

PE jaw crusher is commonly used throughout the industry to reduce the pieces into the required sizes and to impart fineness to the broken material with high quality and efficiency. It can make rocks, sandstones, river pebbles, and other materials into various granularity that meet the requirements of construction sand with high compressive strength, being more in line with building requirements, and characteristic of improving building quality.

Good Feedback

On the basis of in-depth research on the mechanism of rock crushing, our company adopts advanced technology from Europe and the United States to develop and design jaw crushers that meet the needs of the domestic market. Compared with similar domestic products, this product has the characteristics of advanced structure, lightweight, convenient installation, reliable operation, simple operation, high output, large crushing ratio, high efficiency, and high yield, and has reached the international advanced level.

Hot Searches