- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5064*2284*1978

-

Warranty:

-

18 Monthes

-

Power (kW):

-

190 kW

-

Weight (KG):

-

40000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Wind Suction Machine Power:

-

55kw

-

Type of Tire Machinery:

-

Cycle Tire Machine

-

Service Life:

-

≥15 Years

-

Smooth roll diameter (mm):

-

560

-

Front roll linear speed (m/min):

-

25.56

-

Roll working length (mm):

-

800

-

Usage:

-

crush waste tyres

-

Customized:

-

Customized

-

Certification:

-

ISO9001:2008/CE/SGS

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shun Cheong

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5064*2284*1978

-

Warranty:

-

18 Monthes

-

Power (kW):

-

190 kW

-

Weight (KG):

-

40000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Wind Suction Machine Power:

-

55kw

-

Type of Tire Machinery:

-

Cycle Tire Machine

-

Service Life:

-

≥15 Years

-

Smooth roll diameter (mm):

-

560

-

Front roll linear speed (m/min):

-

25.56

-

Roll working length (mm):

-

800

-

Usage:

-

crush waste tyres

-

Customized:

-

Customized

-

Certification:

-

ISO9001:2008/CE/SGS

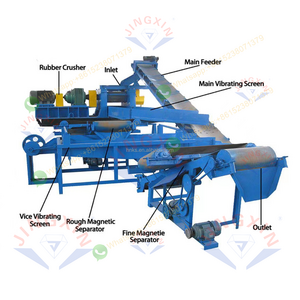

High popular full automatic tire recycle plant / whole tyre production line with whole tire cutter

Application

Waste tire recycling line is used to make the tire into rubber powder.

Waste tire recycling machine, waste tire recycling equipment prices for sale, waste tyre recycling plant cost is used to crush the waste tire into rubber powder.

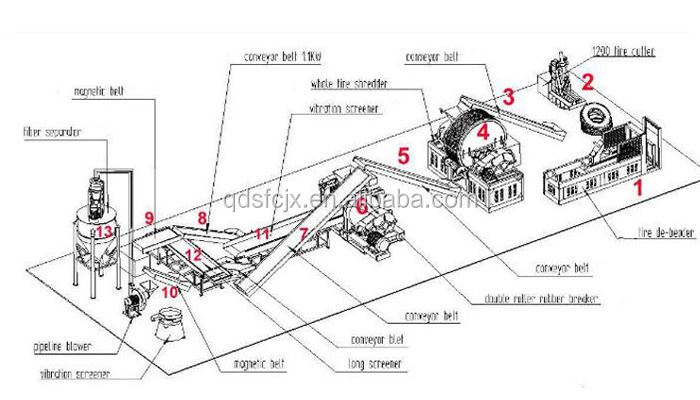

Semi-Automatic Rubber Powder Production Process

Waste Tires -→ Single Hook Debeader -→ Whole Tire Cutter -→ Whole Tire Shredder -→ Rubber Cracker Mill -→Vibrating Screen, Belt Conveyor, Magnetic Plants -→ Fiber Separator -→ 0-30mesh rubber powder -→ Fine Rubber Powder Pulverizer -→ 30-120mesh Rubber Powder

Main Equipment Display

Hook Debeader Whole Tire Cutter

Usage: Pulling out the wire loops from Cut the waste tires blocks into several the mouth of waste tires parts and will be more convenient

for tire shredder machine shredding.

Whole Tire Shredder Auxiliary Equipment

Usage: At the general temperature, the large This whole set of auxiliary equipments

tire blocks can be shredde d directly into includes big conveyor equipment,small

50*50 mm tire block s conveyor equipment, big magnet separator etc.

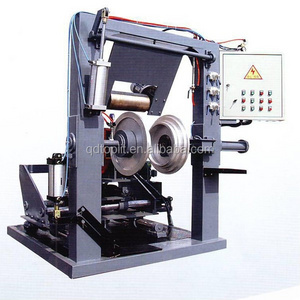

Rubber Cracker Mill

Packing and Shipping

Equipment painting completed before delivery, and then wrapped with stretch film, avoid rubbing the paint off the surface, wooden packaging can be customized, key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and then packed in wooden cases.

About Us

Qingdao shun cheong rubber machinery manufacturing co.,ltd is a chinese manufacturer with establishment in 2007, and have 10 years experience in making various of rubber machines area, also pass the ISO 9001:2008 , SGS, CE certificates too.

our factory major in rubber kneader/rubber mixing mill ; various of plate vulcanizing press ; 2 roll/3 roll/4 roll rubber calender; rubber batch off cooler; waste tire recycling line;reclaimed rubber production line;conveyor belt production line;rubber seals extruding &vulcanizing line etc...

Market: our machineries have exported to America, Mexico, ndia, Vietnam, South Africa, Singapore, Malaysia, Indonisia, Australia, Sri Lanka and many other countries and regions

Professional engineers and teams, then basing on customer requirements, we accept OEM*ODM machines, also oversea engineer service is available.

Certificate

Qingdao Shun Cheong Machinery Co.,Ltd is a professional manufacture of various vulcanizing press and press machine.Our company has passed ISO9001:2008 Quality Mangement System Certification and our products have qualified with Sweden SGS Certificate,and CE Certificate.

FAQ

1. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big production line usually takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production manufacturers.

If you come to our factory, we can show the user around us.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao liuting airport. We will pick up you at the airport.

Contact Us

Winni Xue

Tel: +86 13869845339

Whatsapp: +86 13869845339