- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

depends on customer choice

-

Cutting Thickness:

-

depends on materials

-

Control Software:

-

cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

HGTECH

-

Weight (KG):

-

4000 KG

-

Product name:

-

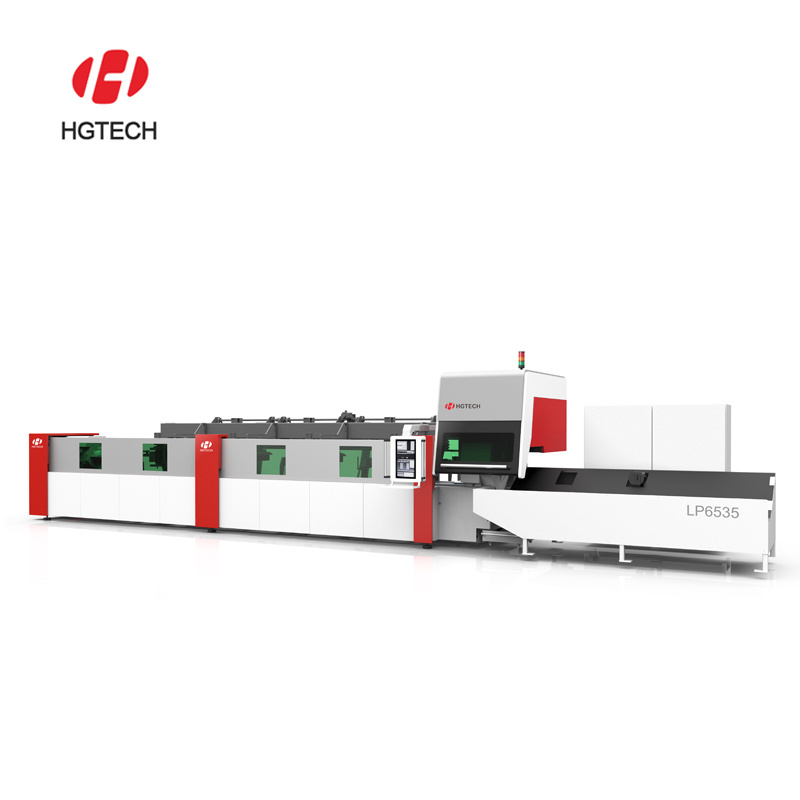

Tubue Fiber Laser Metal Cutting Machine

-

Laser power:

-

1000W / 2000W / 3000W/4000W

-

Color:

-

White Red

-

Function:

-

Cutting Tube Metal Materials

-

Laser source:

-

Raycus IPG

-

Application meterial:

-

Carbon Steel Stainless Copper Metal

-

Feature:

-

Automatically Position

-

Item:

-

High Cutting Speed Tubge Laser Cutting Machinery

-

Material:

-

Stainess Steel

-

Cooling system:

-

Water Cooling

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

depends on materials and thickness

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

depends on customer choice

-

Cutting Thickness:

-

depends on materials

-

Control Software:

-

cypcut

-

Place of Origin:

-

China

-

Brand Name:

-

HGTECH

-

Weight (KG):

-

4000 KG

-

Product name:

-

Tubue Fiber Laser Metal Cutting Machine

-

Laser power:

-

1000W / 2000W / 3000W/4000W

-

Color:

-

White Red

-

Function:

-

Cutting Tube Metal Materials

-

Laser source:

-

Raycus IPG

-

Application meterial:

-

Carbon Steel Stainless Copper Metal

-

Feature:

-

Automatically Position

-

Item:

-

High Cutting Speed Tubge Laser Cutting Machinery

-

Material:

-

Stainess Steel

-

Cooling system:

-

Water Cooling

HGTECH 1000w 3KW metal round square tube and metal sheet cnc fiber laser cutting machine price

Tube and rectangular tube can finish full automatic feeding without human operation . Deformed tubes can achieve artificial semi-automatic feeding. The fast corner response improves cutting efficiency greatly . The workpieces can be unloaded automatically in different areas after cutting .

LT Series is a milestone advancement in new fiber laser cutting technology. Specifically designed for high volume cutting of tubes and pipes the LT series provide far greater efficiency than normal laser systems when cutting pipes and tubular metals.Tube and rectangular tube can finish full automatic feeding without human operation. Deformed tubes can achieve artificial semi-automatic feeding. The fast corner response improves cutting efficiency greatly. The workpieces can be unloaded automatically in different areas after cutting.

|

Parameter |

LT9035 |

LT7535 |

|

Processing Range |

20x10mm- 180x180mm |

20x10mm- 180x180mm |

|

Standard Material |

CS, SS, ALU Alloy |

CS, SS, ALU Alloy |

|

Cutting length |

Max. Length 7500mm |

Max. Length 8500mm |

|

Automatic feeding Pipe length |

2000- 9000mm |

2000- 9000mm |

|

Feeding stand bearing |

4000KG |

4000KG |

|

CNC Axis No. |

12 |

12 |

|

CNC |

Siemens 840D |

Siemens 840D |

|

Laser Source |

1000—4000W |

1000—4000W |

|

Material |

Thickness |

LaserPower |

Cutting Speed [m/min] |

Cutting Gas |

Gas Pressure [bar] |

|

Mild Steel |

1 |

2000 W |

9,10 |

O2 |

4 |

|

|

2 |

|

5,60 |

|

2,5 |

|

|

3 |

|

3,70 |

|

2,5 |

|

|

4 |

|

3,10 |

|

1,5 |

|

|

5 |

|

2,30 |

|

1,5 |

|

|

6 |

|

2,00 |

|

1,5 |

|

|

7 |

|

1,50 |

|

1,5 |

|

|

8 |

|

1,40 |

|

1,5 |

|

|

9 |

|

1,10 |

|

1,5 |

|

|

10 |

|

0,80 |

|

1,5 |

|

|

11 |

|

0,50 |

|

1,5 |

|

Stainless Steel |

1 |

|

4,60 |

N2 |

10 |

|

|

2 |

|

2,80 |

|

12 |

|

|

3 |

|

1,80 |

|

12 |

|

|

4 |

|

1,60 |

|

12 |

|

|

5 |

|

1,20 |

|

14 |

Industry Applications of Fiber metal tube cutting laser machine for circular tube LT Take the oil industry for example, the main route of oil transport is the pipeline, and because of the characteristics of the oil itself, leading to the high quality requirements of the pipeline. While fiber laser cutting machine can achieve the pipes multi-angle precision processing to fulfil the oil transportation requirement.

Professional tube fiber laser cutting machine—LT is used for cutting square tube, rectangular tube, oval tube, waist type tube, hexagonal tube; square tube 20 * 20x150 *150mm, round tube Φ20-Φ 210mm wall thickness of 0.5-10mm carbon steel tube, 0.5-10mm stainless steel tube.

Our service

---Pre-Sales Service

Free Pre-Sales Consulting / Free Sample Marking

Speedy

Laser offer 12 hours quick pre-sales response and free consulting. Any kind of technical support are available for users.

Free Sample Making is available.

Free Sample Testing is available.

We offer progressing solution design to all the distributor and users.

---After-sales Services

1. 2 year guarantee for main machine (People damaged are charged).

2. Full technical support\ by e-mail, call and video

3. Lifelong maintenance and spare parts supply.

4. Free design of fixtures as customers required.

5. Free training installation and operation for the staffs.