- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

8000

-

Application:

-

Casting Industries

-

After Warranty Service:

-

Video technical support, Online support, Spare parts,

-

Capacity:

-

3000~12000tons/year

-

Feature:

-

High casting accuracy

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Productivity:

-

80-100 box/hour

-

Usage:

-

Steel casting prduction

-

Advantage:

-

One-stop service

-

Technology:

-

Clay Sand Technology

-

Product name:

-

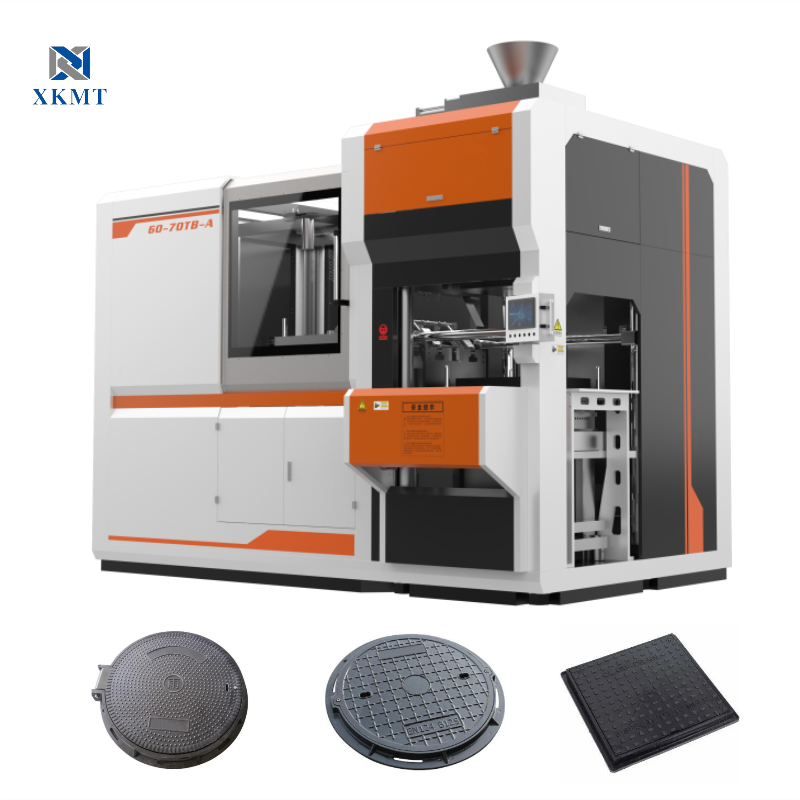

Automatic Green Sand Molding Machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

metal casting machine

-

Brand Name:

-

XKMT

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

8000

-

Application:

-

Casting Industries

-

After Warranty Service:

-

Video technical support, Online support, Spare parts,

-

Capacity:

-

3000~12000tons/year

-

Feature:

-

High casting accuracy

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Productivity:

-

80-100 box/hour

-

Usage:

-

Steel casting prduction

-

Advantage:

-

One-stop service

-

Technology:

-

Clay Sand Technology

-

Product name:

-

Automatic Green Sand Molding Machine

Products Description

AUTOMATIC CASTING MOLDING MACHINE

The molding machine adopts double-sided template, pneumatic sand feeding. Uniform hardness, flask closing high precision and adjustable sand thickness, easy replacement of template.

The hydraulic oil temperature control ensures the best running state of the equipment.

Product Paramenters

|

Product Name

|

1000

|

Green Sand Automatic Horizontal Parted Flaskless Shoot Squeeze Casting Molding Machine

|

Rear axde,brake drum,counter weight

|

||

|

Sand size(mm)

|

|

500*400*150/150/550*450*150/150

|

|

||

|

5-10

|

1000

|

610*508*130-180/130-180/660*508*130-180/130-180

|

Gray iron castings, counter weight for forklifts,loaders etc

|

||

|

|

|

700*600*130-180/130-180/600*600*130-180/130-180

|

|

||

|

Productivity (sec/pcs)

|

|

36-40 sec/mold 90molds/h (Time does not contain the core setting)

|

|

||

|

Compaction ratio (Mpa)

|

|

0.7-0.9

|

|

||

|

Air consumption (m³/Min)

|

|

1.6

|

|

||

|

Work pressure (Mpa)

|

|

8.5

|

|

||

|

Power(Kw)

|

|

15

|

|

||

|

Sand consumption(T/h)

|

|

10

|

|

||

Workpiece

1.W

hat services can you provide if I want to invest a casting molding line

?

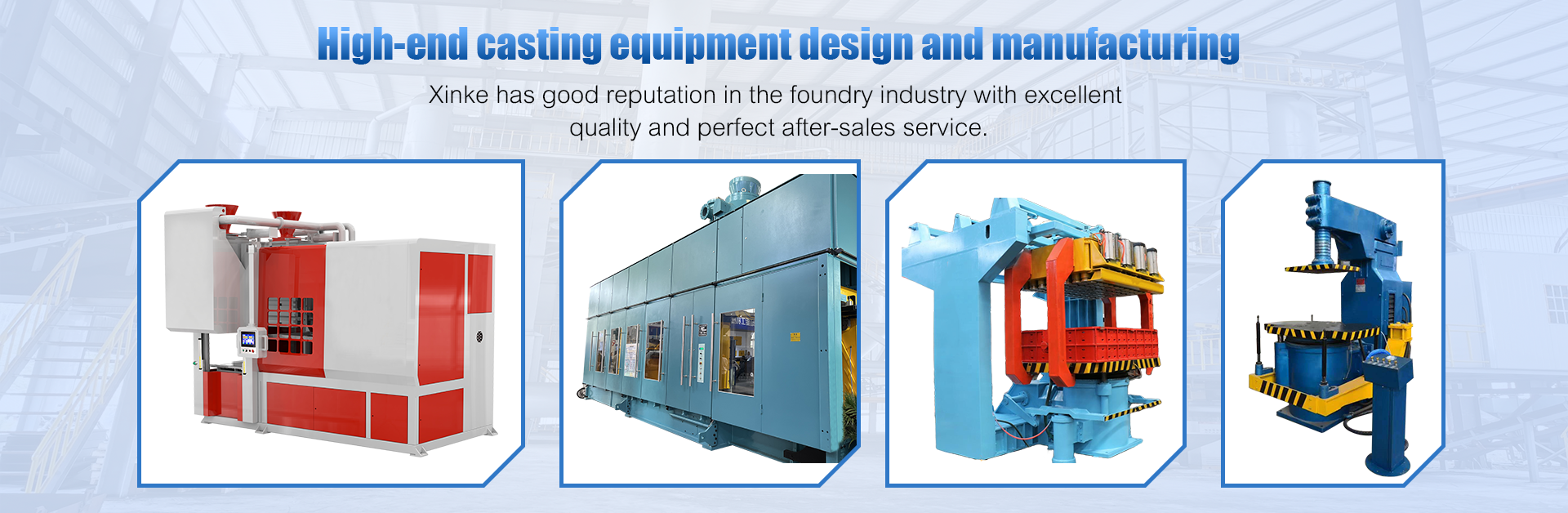

-Xinke has m

ore than 30 year experience in foundry machine industry, we

can provide the one-stop solution for the e

ntire production line.

-Around 20 s

enior engineers, we will provide the

free and fast solution scheme.

-

We can provide you with all the equipment you need for your molding line, including shot blasting machines, furnaces, etc.

2.

How do you handle after sales

?

-Xinke has some overseas after-sales service points

.

-We provide full English documents, including foundation drawings, manual book, electric wiring diagram, electric manual book and maintenance book, etc

.

-We will train your workers in operation and simple repairs.

-Customer service 24/7 hours on line.

3.What's the quality guarantee time?

-12 months after the date of commissioning completion for whole machine.

-Spare parts always supply in time.

4.Are you able to give installation and commissioning overseas?

-We can send technicians for installation and commissioning guidance.

-Buyer

is responsible for their salary, travel expenses, round trip

tickets, food, a

ccommodation and insurance

, etc.

Hot Searches