- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

O

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FONFAR

-

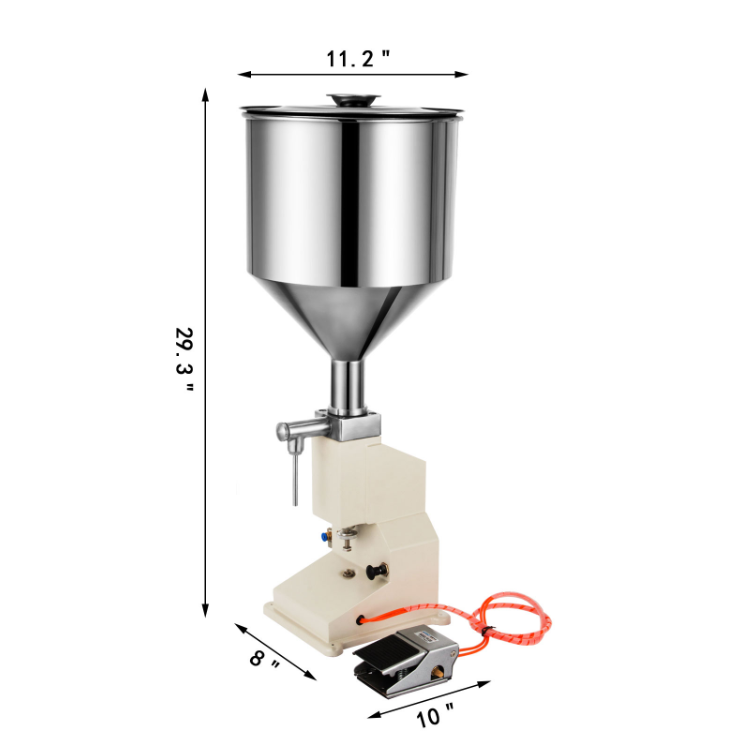

Dimension(L*W*H):

-

340*340*800MM

-

Weight:

-

12 KG

-

Product name:

-

Nail polish filling machine

-

Filling Speed:

-

20-60 bottles/min

-

Filling Range:

-

5-50ml

-

Hopper capacity:

-

10L

-

Filling accuracy:

-

±0.5%

-

Filling material:

-

Liquid or cream

-

Material:

-

Stainless Steel

-

Nozzle:

-

Single Nozzle

-

Function:

-

Filling machine

Quick Details

-

Machinery Capacity:

-

500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Wood

-

Filling Material:

-

Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1%

-

Voltage:

-

O

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FONFAR

-

Dimension(L*W*H):

-

340*340*800MM

-

Weight:

-

12 KG

-

Product name:

-

Nail polish filling machine

-

Filling Speed:

-

20-60 bottles/min

-

Filling Range:

-

5-50ml

-

Hopper capacity:

-

10L

-

Filling accuracy:

-

±0.5%

-

Filling material:

-

Liquid or cream

-

Material:

-

Stainless Steel

-

Nozzle:

-

Single Nozzle

-

Function:

-

Filling machine

Pneumatic nail polish filling machine/cream filling machine for tubes bags bottles/ liquid chili paste filling

Products Description

Description of Pneumatic paste liquid filling machine

It is suitable for filling liquids, pastes and other substances in chemical, food, daily chemical, pharmaceutical, pesticide, lubricating oil and other industries. The cylinder, casing, and hopper are all made of stainless steel, the piston is made of polytetrafluoroethylene, and the pneumatic parts are all imported pneumatic components, which meet GMP requirements. Filling volume and filling speed can be adjusted arbitrarily, foot switch and automatic filling function, high precision, simple structure and convenient operation.

Feature of Pneumatic paste liquid filling machine

* Adopt pneumatic operation does not need other power, simple operation, high filling precision;

* Small, low cost;

* Using 304 stainless steel construction of material contact parts, stainless steel valve system design;

* Filling volume, filling speed can be adjustable, bottom close positive shutoff nozzles ensure drip free operations;

* Extremely easy to clean and maintain;

* Small footprint for simple bench mounting;

* Conform to GMP;

* Small, low cost;

* Using 304 stainless steel construction of material contact parts, stainless steel valve system design;

* Filling volume, filling speed can be adjustable, bottom close positive shutoff nozzles ensure drip free operations;

* Extremely easy to clean and maintain;

* Small footprint for simple bench mounting;

* Conform to GMP;

|

Model

|

FF-A02

|

|

Voltage

|

AC220V/50HZ 110V/60HZ

|

|

Driven Type

|

Pneumatic

|

|

Filling speed

|

20~60pcs/min

|

|

Capacity

|

10L

|

|

Error

|

±0.2-1ml

|

|

Bottle Height Range

|

100-300 (mm)

|

|

Machine Weight

|

12 KGS

|

|

Machine Size

|

340*340*800mm

|

Recommend Products

Package&Shipping

Contact Us

Hot Searches