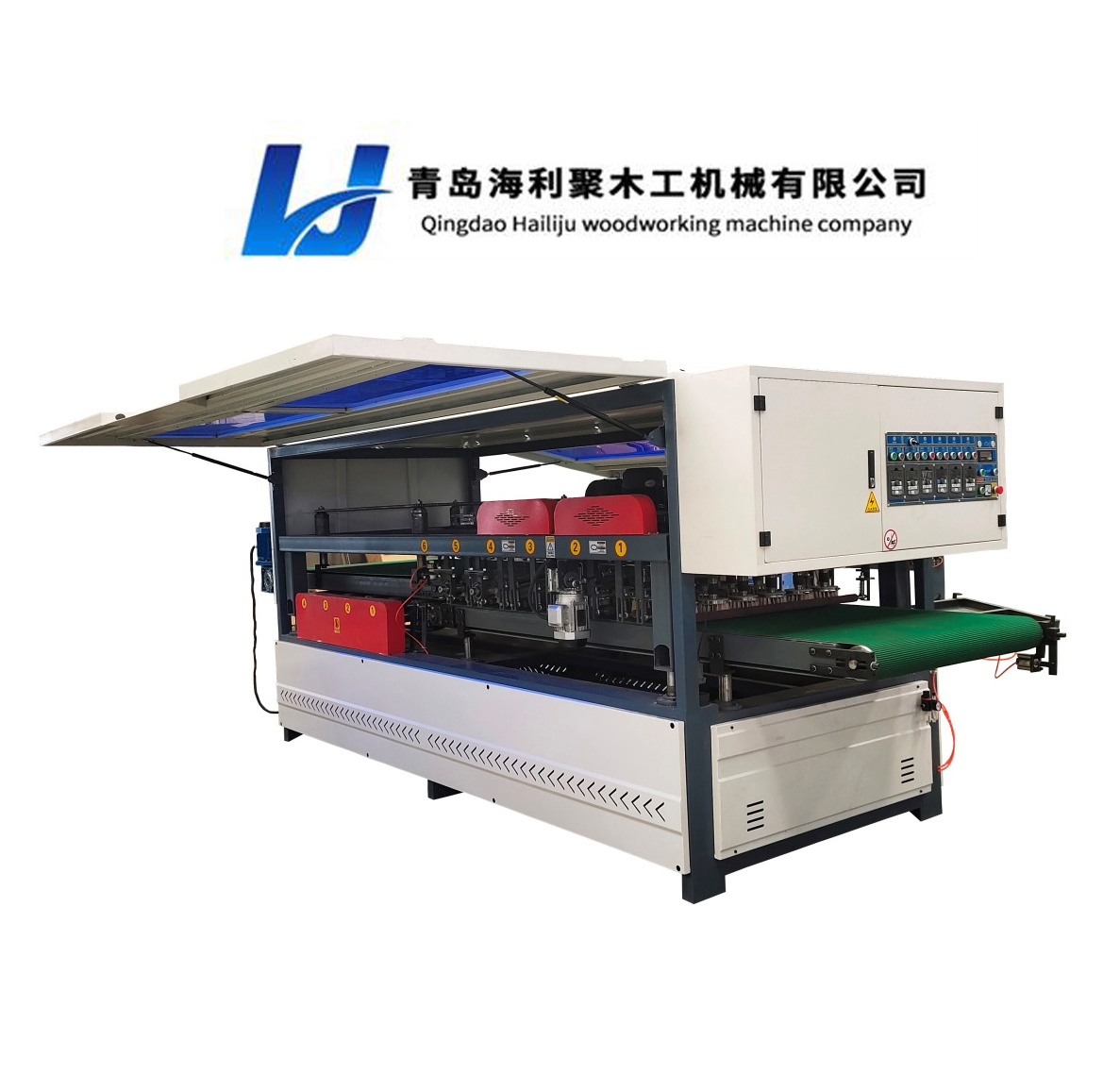

WOOD DOOR BRUSH PROFILE SANDER SANDING POLISHING MACHINE

It is suitable for rough and fine sanding, grinding and polishing of all kinds of solid wood, density board, veneer board, straight line (such as door edge line, door frame, corner line, photo frame frame frame, shutter, etc.), L-shaped wood line, regular surface, special-shaped surface, plane and special-shaped surface, primer wood door, cabinet door surface

- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

11.6KW

-

Name:

-

Automatic Combination Door Cabinet Machine

-

Application:

-

MDF/WOOD

-

Usage:

-

Sanding Surface

-

Voltage:

-

380V 50HZ 3phase

-

Feeding speed:

-

5-30m/min

-

Certification:

-

ISO CE

-

Keywords:

-

Wood Disc Brush Polish Sanding Sander Machine

-

Woodworking Machine:

-

Wood Pallet Block Production Line

-

Working thickness:

-

2-110 Mm(Customizable 2-350 Mm)

-

Air pressure:

-

0.6-0.8Mpa

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

HAILIJU

-

Weight (KG):

-

2600 KG

-

Power (kW):

-

11.6KW

-

Name:

-

Automatic Combination Door Cabinet Machine

-

Application:

-

MDF/WOOD

-

Usage:

-

Sanding Surface

-

Voltage:

-

380V 50HZ 3phase

-

Feeding speed:

-

5-30m/min

-

Certification:

-

ISO CE

-

Keywords:

-

Wood Disc Brush Polish Sanding Sander Machine

-

Woodworking Machine:

-

Wood Pallet Block Production Line

-

Working thickness:

-

2-110 Mm(Customizable 2-350 Mm)

-

Air pressure:

-

0.6-0.8Mpa

Products Description

WOOD DOOR BRUSH PROFILE SANDER SANDING POLISHING MACHINE

Product Paramenters

|

WOOD DOOR BRUSH PROFILE SANDER SANDING POLISHING MACHINE

|

|

|

||

|

Parameter specification

|

MP-1000-2YHP

|

MP-1300-2YHP

|

||

|

WORKING WIDTH

|

1000MM

|

1300MM

|

||

|

WORKING LENGTH

|

≥320MM

|

≥320MM

|

||

|

WORKING THICKNESS

|

5-110mm

|

5-110mm

|

||

|

CONVEYING SPEED

|

0-25m/s

|

0-25m/s

|

||

|

TOTAL POWER

|

13.87kw

|

15.47kw

|

||

|

POLISHING SPEED

|

FREQUENCY CONTROL

|

FREQUENCY CONTROL

|

||

|

AVERAGE SUCTION VELOCITY

|

≥25m/s

|

≥25m/s

|

||

|

OVERALL MACHINE SIZE

|

3650*1850*1800mm

|

3650*2150*1800mm

|

||

|

PACKAGE SIZE

|

2200*1950*2100mm

|

2200*2150*2100mm

|

||

|

GROSS WEIGHT

|

2200KG

|

2600KG

|

||

Details Images

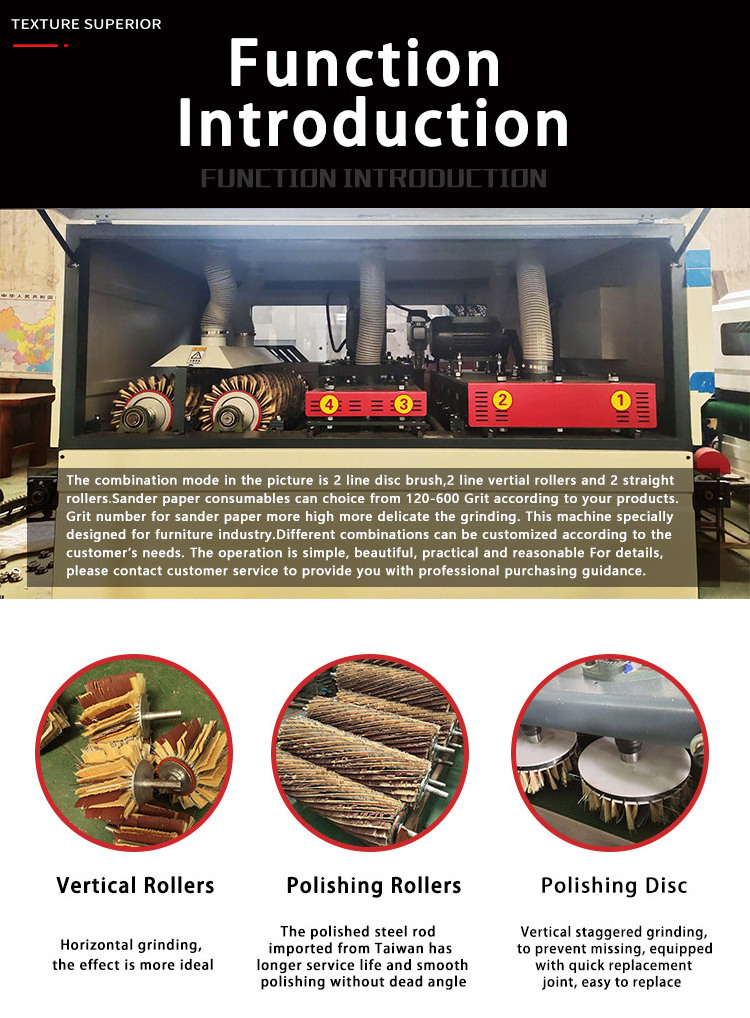

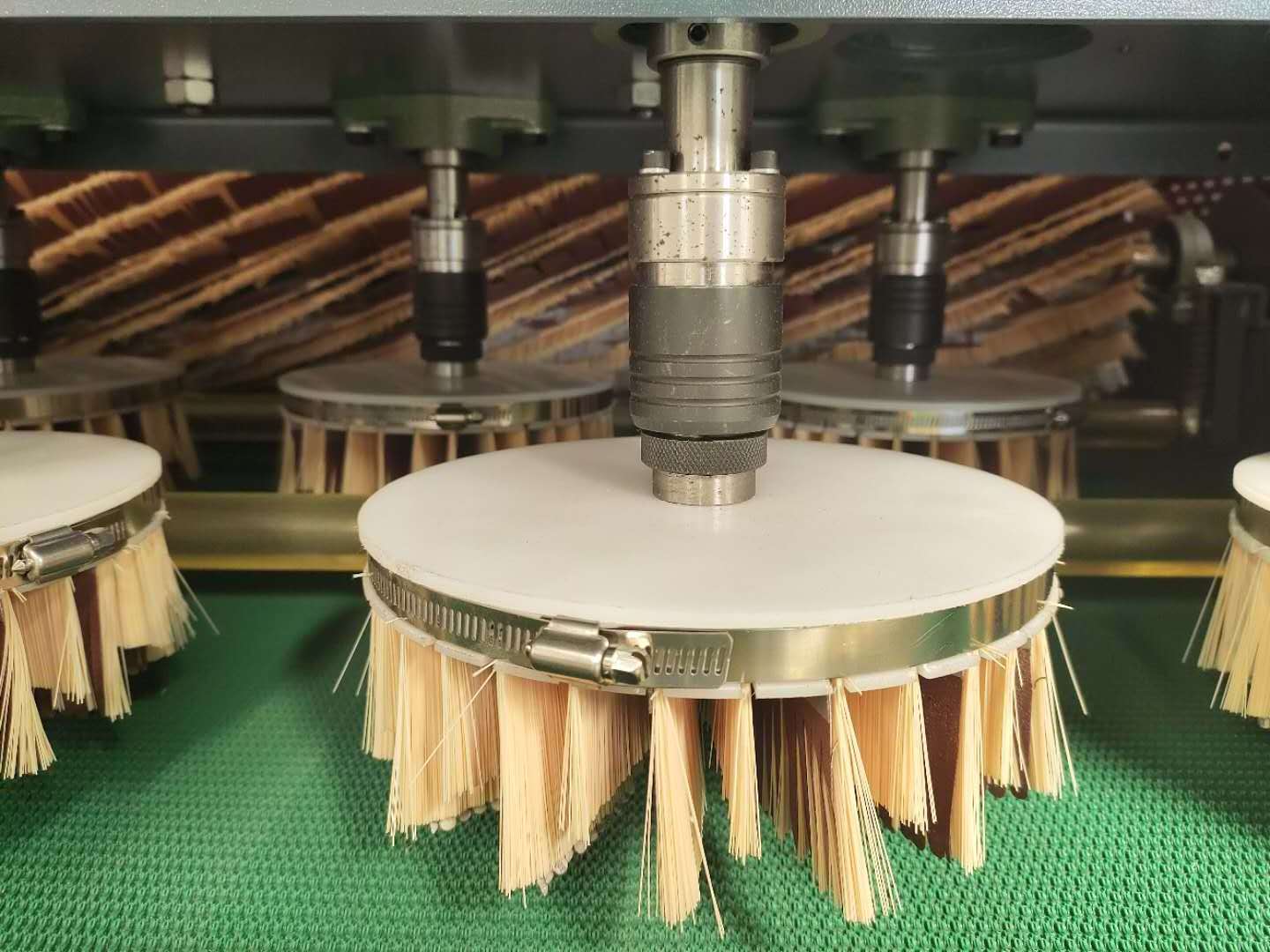

The combination mode in the picture is 2 line disc brush,2 line vertial rollers and 2 straight rollers.Sander paper consumables can choice from 120-600 Grit according to your products. Grit number for sander paper more high more delicate the grinding. This machine specially designed for furniture industry.Different combinations can be customized according to the customer’s needs. The operation is simple, beautiful, practical and reasonable For details, please contact customer service to provide you with professional purchasing guidance.

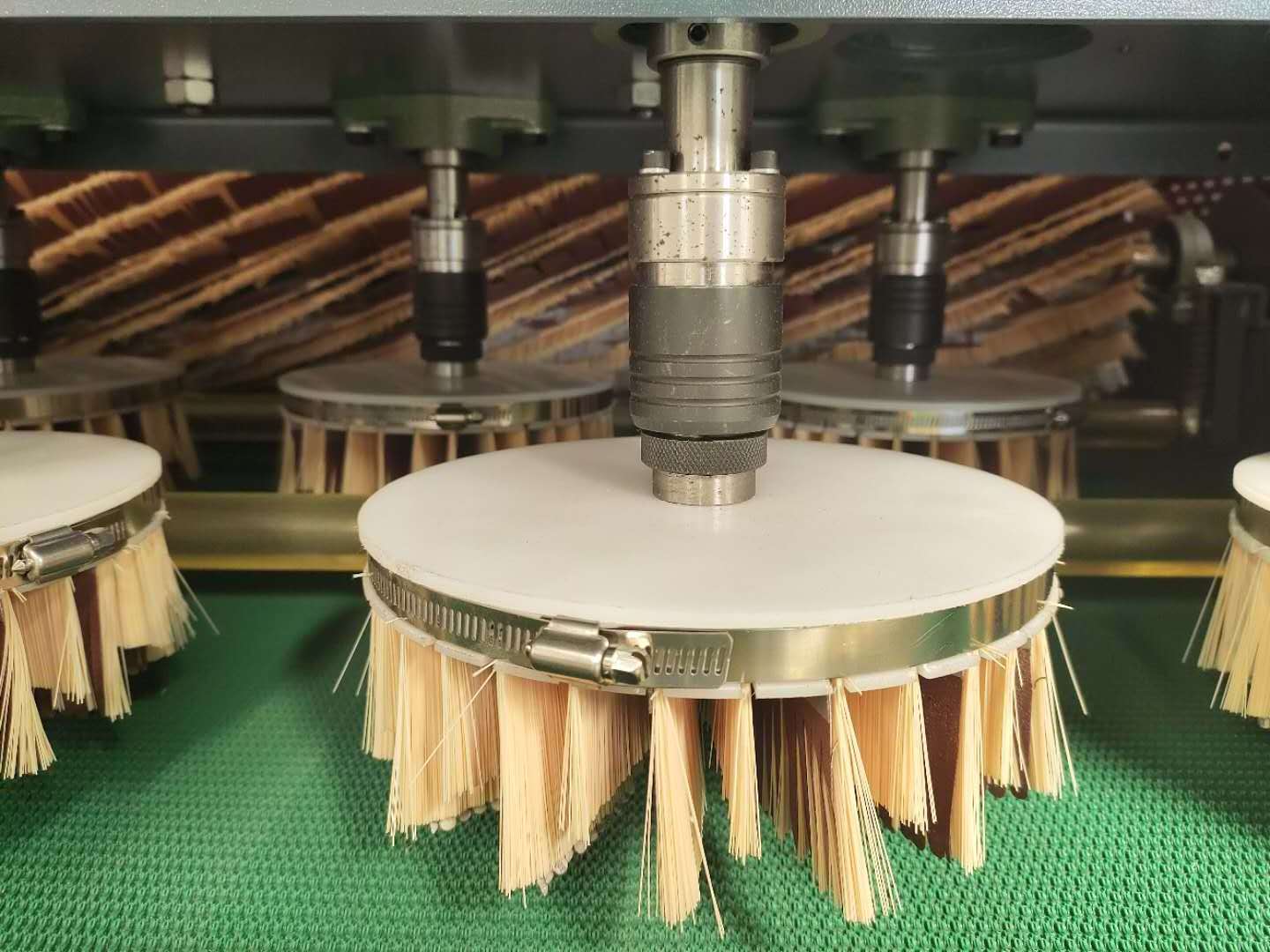

Polishing Disc

Vertical staggered grinding,

to prevent missing, equipped

with quick replacement

joint, easy to replace

Vertical Rollers

Horizontal grinding,

the effect is more ideal

Polishing rollers

The polished steel rod

imported from Taiwan has

longer service life and smooth

polishing without dead angle

Disc Rollers Can Design Number

To meet the needs of your material polishing process, the thickness of polishing can also be customized

DISC POLISHING

The vertical grinding plate (the grinding disc can swing left and right) can realize the deep cleaning of the gap. It is equipped with quick replacement joint, which can make the disc replacement more convenient.

VERTICAL POLISHING

The two groups of longitudinal rollers can swing left and right, and the swing direction of the two groups of longitudinal rollers can be opposite, so as to realize 360 degree grinding without dead angle, eliminate missing and wrong beating, so as to improve the grinding efficiency.

Polishing roller

Using the polishing steel roller imported from Taiwan, different number of sandpaper and sisal strip can be matched according to the hardness of the grinding material to further refine the grinding

01 Control Panel

Button control panel, plate thickness up and dwon, processing simple, easy to understand

02 F

eeder

The conveyor belt is equipped with cast iron gearbox reducer motor as standard,

which is not easy to deform. It will not affect the fuselage during long-term operation at high temperature. The service life of the machine body is lengthened and the conveying can be adjusted at will, which is more convenient

03 IMPORTED REDUCER

Standard cast iron gearbox reducer motor, compared with the gearbox is not easy to deform, high temperature operation will not have an impact on the machine, enhance the life of the machine, command transmission can be adjusted at will, more worry free Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

04 OIL WATER SEPARATOR

Oil water separator, can effectively prevent the water vapor in the air from entering the machine, use safely, and ensure the safety of the machine in use

05 Magnetic ring induction of lifting motor

Lifting motor magnetic ring induction, higher accuracy, use of altimeter upgrade, longer service life

06 AUTOMATIC DEVIATION CORRECTION

Start the automatic deviation correction design to ensure that the product does not deviate, the service life of the conveyor belt is longer, and it can still be effectively polished at high speed

07 FREQUENCY CONVERSION CONTROL CABINET

The frequency conversion is stable, and the frequency converter with high-end imported accessories is used, which is sensitive and safe to ensure the safety and service life of the machinery. Moreover, the conveyor belt is equipped with frequency conversion, which is convenient for use and speed regulation, improves work efficiency and saves labor cost

Processing Effect Display

Factory Display

Product packaging

Hot Searches