- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

140 mm

-

Ejector Force(kN):

-

42 kN

-

Theoretical Shot Volume(cm³):

-

371 cm³

-

Injection Rate (g/s):

-

164.8 g/s

-

Injection Weight (g):

-

341.3 g

-

Screw Speed (rpm):

-

1 - 235 rpm

-

Screw diameter (mm):

-

48 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

460x460mm

-

Weight (KG):

-

5000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

420 mm

-

Model Number:

-

UN160A5

-

Brand Name:

-

YIZUMI

-

Power (kW):

-

35.9 kW

-

Injection pressure:

-

162.9Mpa

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Uzbekistan

-

Certification:

-

ISO

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

460mm

-

Distance between Tie Bars(Height)(mm):

-

460mm

-

Mold Height(mm):

-

160 - 520 mm

-

Ejector Stroke(mm):

-

140 mm

-

Ejector Force(kN):

-

42 kN

-

Theoretical Shot Volume(cm³):

-

371 cm³

-

Injection Rate (g/s):

-

164.8 g/s

-

Injection Weight (g):

-

341.3 g

-

Screw Speed (rpm):

-

1 - 235 rpm

-

Screw diameter (mm):

-

48 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

460x460mm

-

Weight (KG):

-

5000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

420 mm

-

Model Number:

-

UN160A5

-

Brand Name:

-

YIZUMI

-

Power (kW):

-

35.9 kW

-

Injection pressure:

-

162.9Mpa

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Uzbekistan

-

Certification:

-

ISO

-

Marketing Type:

-

Hot Product 2019

Product Description

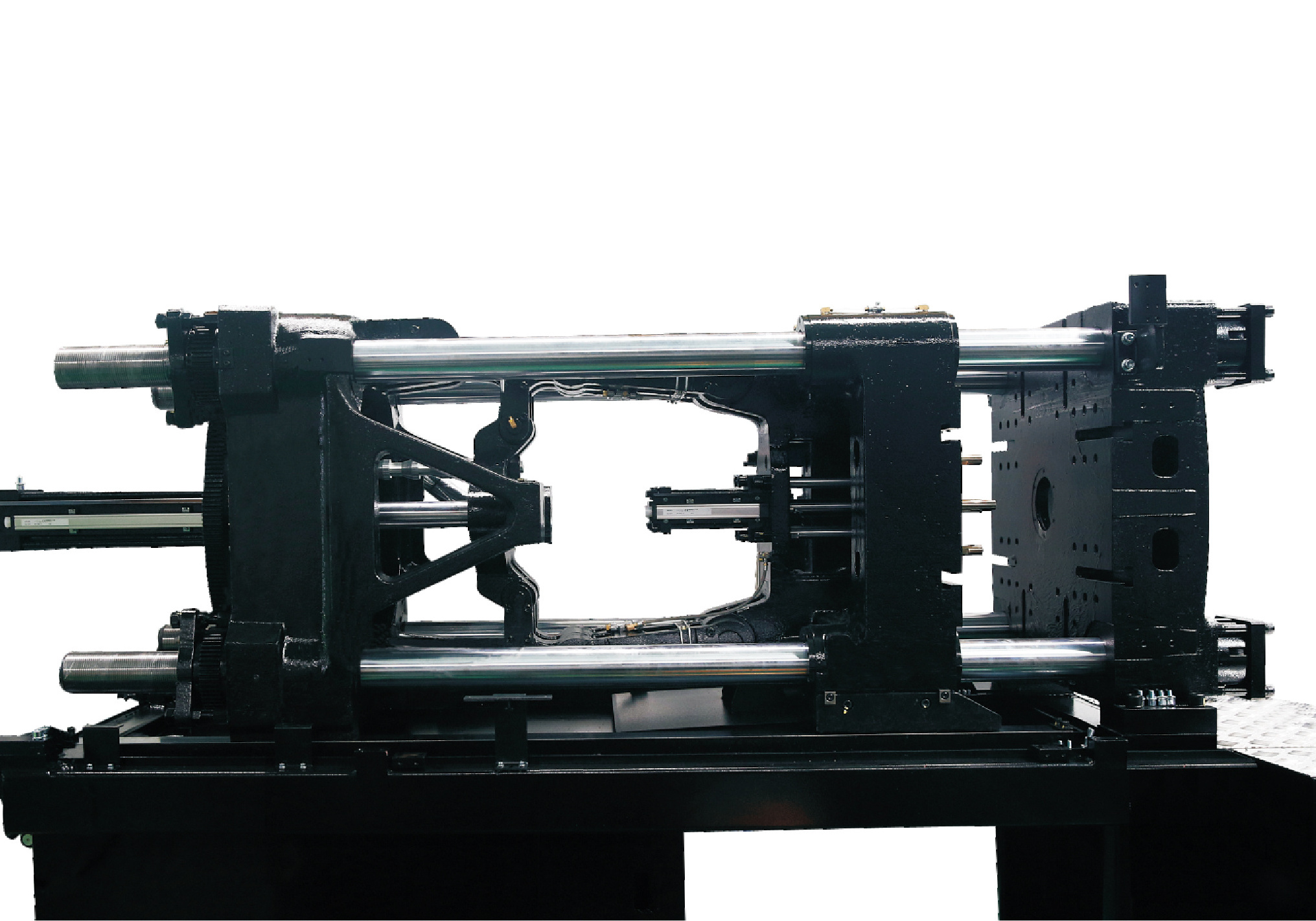

Clamping Unit

T-slot platen and

Compulsory ejector return

T-slot platen can increases the overall rigidity of clamping unit by 30%, brings convenience for installation and removal of mold, reduces the wear of thread due to long-term use of screw hole and extends the life of platen.The compulsory ejector return

meets the requirement of special mold reset and the molds are more applicable.

Anti-tilt platen support design

Special anti-tilt platen support design increases the smoothness of motion, lowers friction, improves the efficiency of motion, reduces energy consumption and prevents the platen from tilting so as to protect the mold.

Closed-loop control of mold open position

The enhanced accuracy and repeatability of mold open position result in accurate part removal by robot and benefit automated continuous production. The mold open position accuracy is smaller than 2mm and repeatability is below 0.3mm.

Low pressure mold protection

Low-pressure mold protection control unit ensures the mold gets

effectively protected.

Injection Unit

Integrated linear guide rail structure

The injection unit is equipped with the one-piece supporting base which is integrated with linear guide rails, which minimizes the friction to motion, increases injection accuracy and enhances plasticizing efficiency.

New universal screw and barrel unit

Movable hopper rails (60T-320T)

Horizontal double-carriage design

Proportional back pressure control

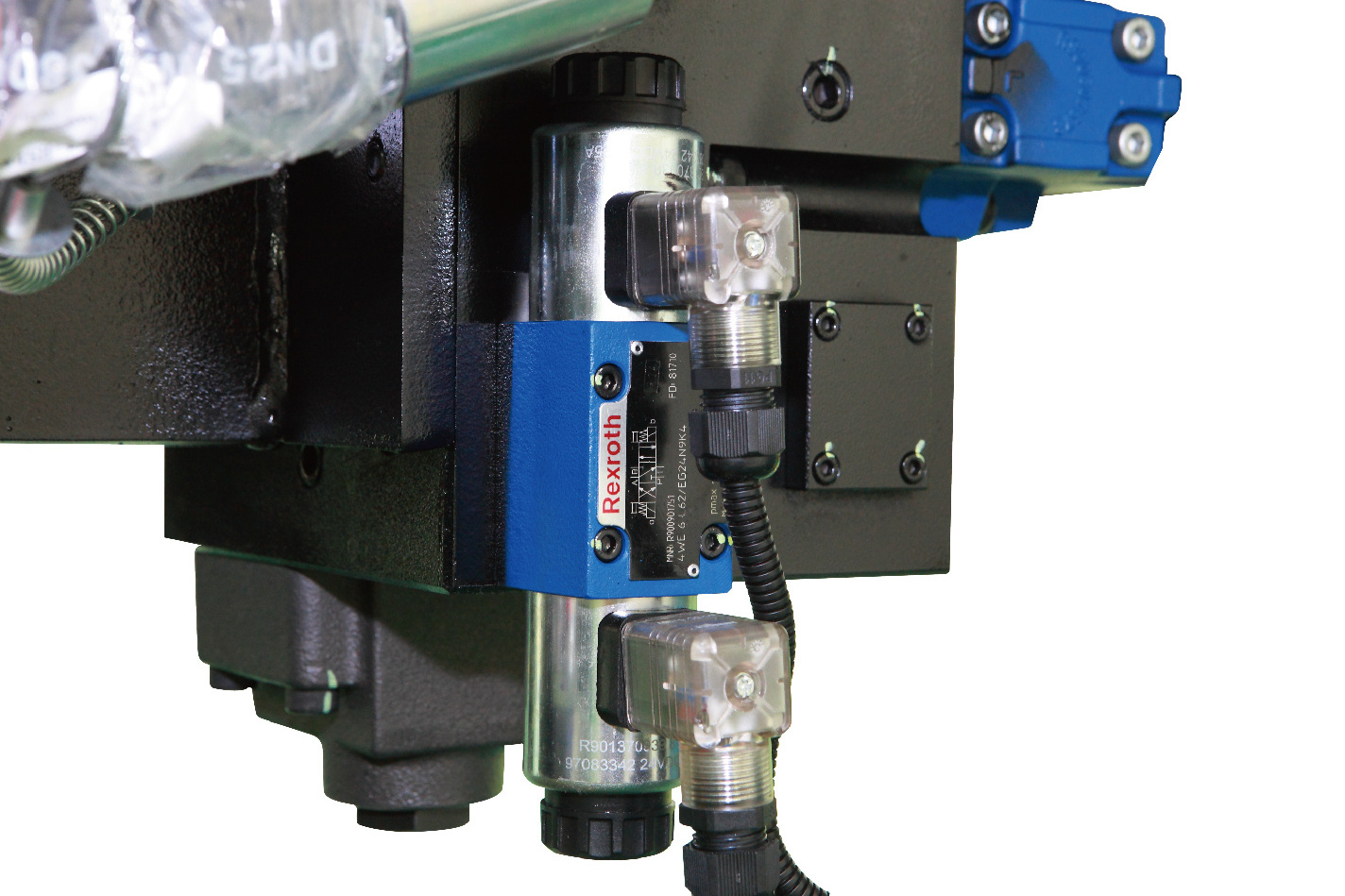

Hydraulic System

The third-generation servo

low energy consumption, strong power and fast response

Overall hydraulic circuit optimization reduces flow loss.

The resistance to moving parts, including the clamping unit and injection unit is further reduced, raising the response speed and reducing frictional loss.

Control System

Mirle MK500 control system delivers better performance in machine control and adds to the stability of product and machine.

1

.CAN open bus technology makes transmission more stable and control more accurate.

2

.10.4-inch 800X 600 TFT LCD with separate control by 32-bit CPU.

3

.The control unit adopts Cortex-A8 processor with scan time of 0.5ms, speedy response and accurate control.

4

.240 sets of mold data memory, USB port for extension of storage.

5

.7+1 sections of PID temperature control supports switchover between type J and type K thermocouples. Automatic PID tuning improves the temperature control accuracy.

6

.Expansion of hot runner interface is available, supporting 60 sets of hot runner and switch over between type J and type K thermocouples (optional).

7

.Production quality control, with display of process parameter graphs and statistics tables.

8

.The I/O module has 64 outputs and 64 inputs at maximum (optional).

9

.Integration of common software meets different injection molding process requirements.

10

.Common communication interface, including RS-232\485, CANOPEN, OPC UA (expand as needed).

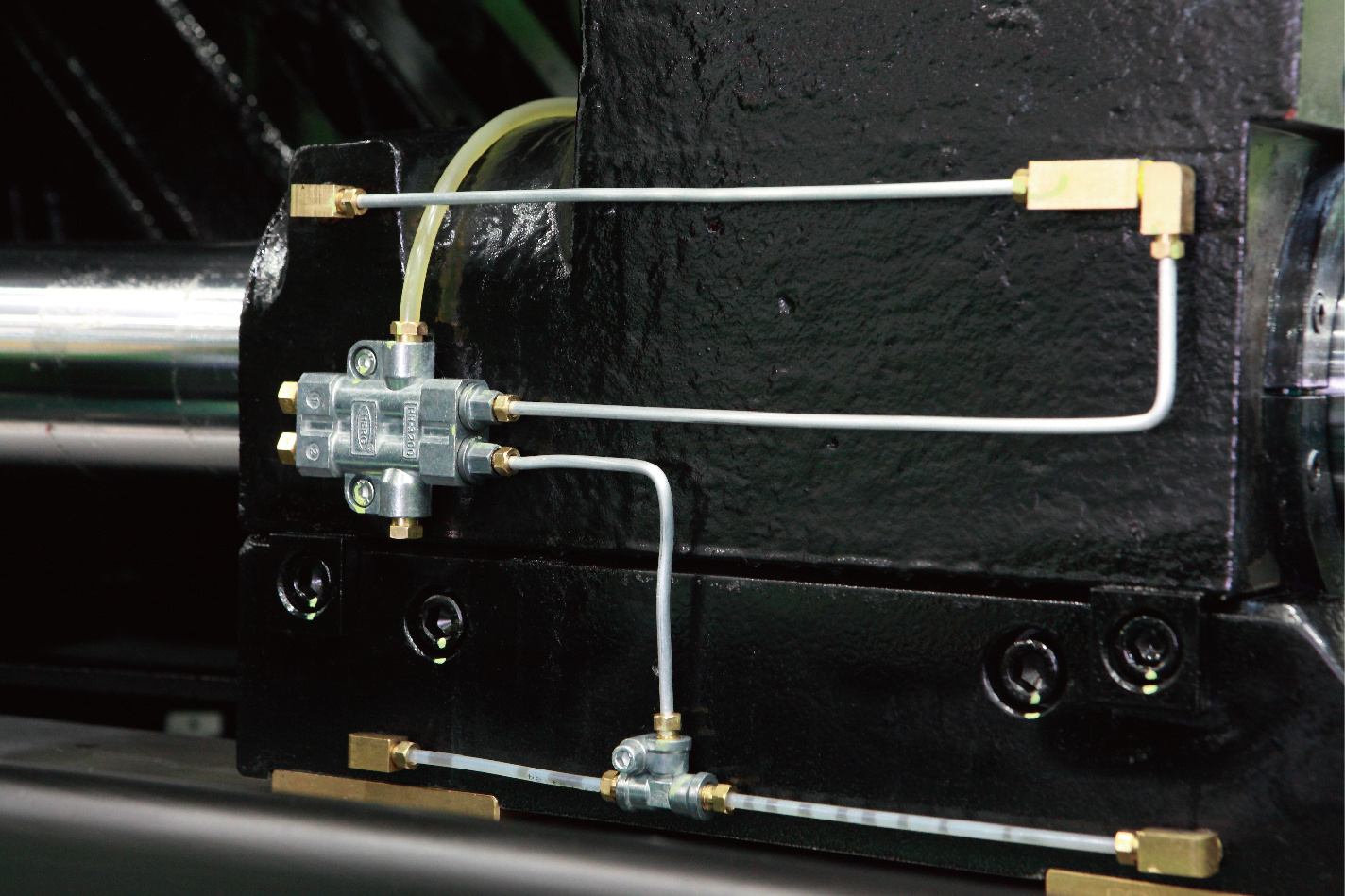

User-friendly Design

EU-based robot mounting holes

Centralized lubrication module

Manual lubrication pump

Electric lubricant pump

Electrical cabinet that is neat ,Safe and maintenance-friendly

Universal standardized interfaces and connectors

Specification

|

|

DESCRIPTION

|

UNIT

|

DATA

|

|

Injection unit

|

Shot volume

|

cm3

|

371

|

|

|

Shot weight (PS)

|

g

|

341.3

|

|

|

|

oz

|

12

|

|

|

Screw diameter

|

mm

|

48

|

|

|

Injection pressure

|

Mpa

|

162.9

|

|

|

Injection rate

|

g/s

|

164.8

|

|

|

Screw L:D ratio

|

|

20:1

|

|

|

Max. injection speed

|

mm/s

|

99

|

|

|

Screw stroke

|

mm

|

205

|

|

|

Screw speed(stepless)

|

r/min

|

0-235

|

|

Clamping unit

|

Clamping force

|

kN

|

1600

|

|

|

Opening stroke

|

mm

|

420

|

|

|

Space between bars

|

mm*mm

|

460x460

|

|

|

Max. Daylight

|

mm

|

940

|

|

|

Mold thickness(Min.Max)

|

mm

|

160-520

|

|

|

Ejector stroke

|

mm

|

140

|

|

|

Number of ejector pin hole

|

|

5

|

|

|

Ejector force

|

kN

|

42

|

|

Power unit

|

Max. system pressure

|

Mpa

|

17.5

|

|

|

Standard servo Pump

|

kw

|

25

|

|

|

Heating power

|

kw

|

10.9

|

|

|

Number of temp control zones

|

|

4

|

|

General

|

Dry cycle time

|

s

|

2.4

|

|

|

Oil tank capacity

|

L

|

220

|

|

|

Machine dimensions(LxWxH)

|

m*m*m

|

5.35x1.37x2.13

|

|

|

Machine weight

|

kg

|

5000

|

NOTE: The listed machine price is for standard machine only, any extra requirement (e.g. CE/UL/KCS safety standard and so on) will be subject to extra charge.

Packing & Delivery

Hot Searches