1. who are we?

We are based in Hebei, China, start from 2016,sell to Africa(60.00%),Southeast Asia(20.00%),Mid East(6.00%),South

America(5.00%),South Asia(3.00%),North America(2.00%),Eastern Europe(2.00%),Western Europe(1.00%),Eastern Asia(1.00%). There are

total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

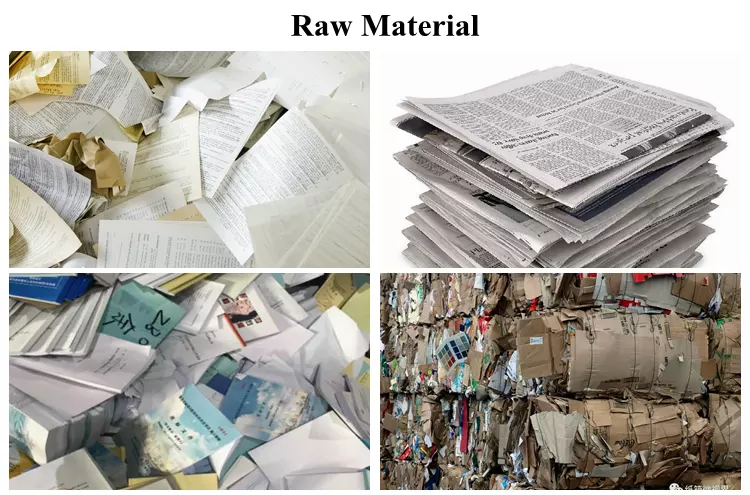

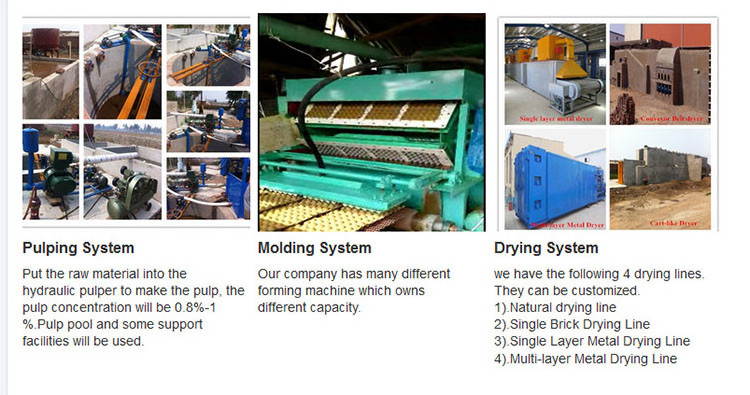

Egg Tray Machine, Paper Egg Tray Machine, Pulp Molding Machine, Paper Egg Tray Making Machine

4. why should you buy from us not from other suppliers?

1. a high quality and professional team 2. more than 20 years for producing egg tray machine 3. the lowest price, the best quality

and after-sale service

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian