- Product Details

- {{item.text}}

Quick Details

-

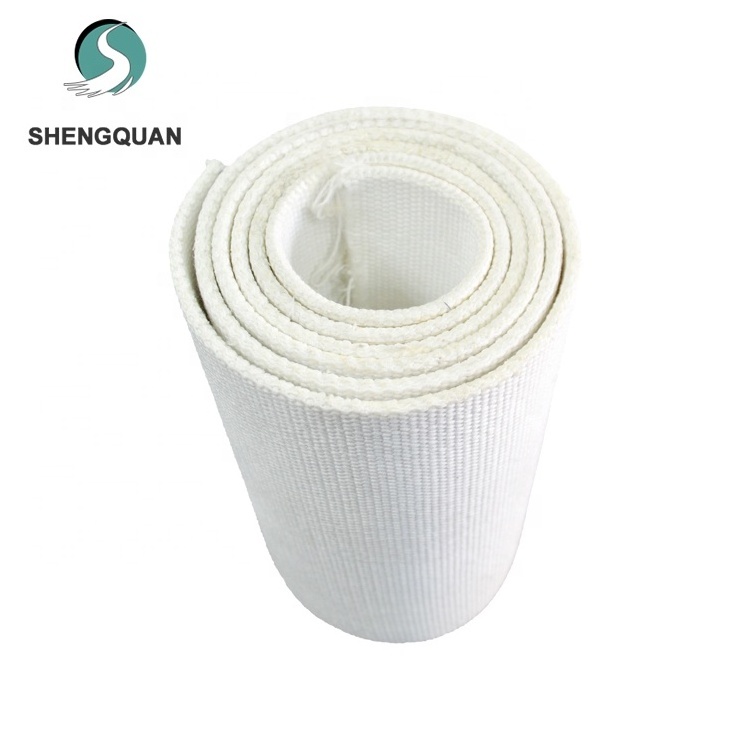

Brand Name:

-

Shengquan

-

Voltage:

-

110-220

-

Certification:

-

ISO 9001

-

thickness:

-

4-8mm

-

ply:

-

2-5

-

weight:

-

3200-4800g/m2

-

Usage:

-

Cement plant or bulk cement

-

Max Width:

-

2600mm

-

Standard or Nonstandard:

-

Standard

-

Supply Type:

-

Make-to-Order

-

Technics:

-

Woven

Quick Details

-

Power:

-

1000

-

Warranty:

-

3 months

-

Place of Origin:

-

Tianjin, China

-

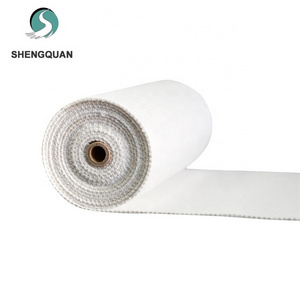

Brand Name:

-

Shengquan

-

Voltage:

-

110-220

-

Certification:

-

ISO 9001

-

thickness:

-

4-8mm

-

ply:

-

2-5

-

weight:

-

3200-4800g/m2

-

Usage:

-

Cement plant or bulk cement

-

Max Width:

-

2600mm

-

Standard or Nonstandard:

-

Standard

-

Supply Type:

-

Make-to-Order

-

Technics:

-

Woven

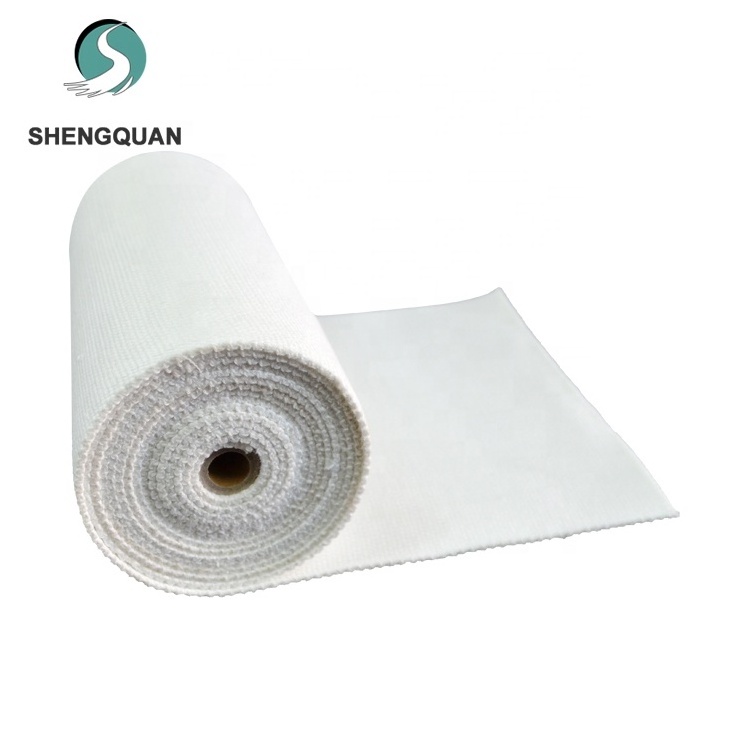

Air slide Fabrics

In cement plant:

An Airslide belt is in the middle of a chute. Powder material will come into the chute above Airslide belt. Material will flow to the chute lower side as pneumatic blower down Airslide belt. That's why we say Airslide belt can move powder material because of the wind power. And then, the rest wind will go out from the top of the chute. Through the moving, no parts moved except powder material. So that it can spare more energy and maintain cost, etc.

fluidization silo:

Our Airslide canvas is installed on the surface of the silo bottom. It is supplied for installation as aeration units on the sloped conical bottoms of bins and silos to aid in the withdrawal of dry relatively free-flowing material.

Each Airslide aeration unit package consists of 200mm open-type. Airslide conveyor units in lengths of 1.5 or 3m depend on the slope length of the conical storage area. Some spoke patterns are normally used with materials which have good fluidization characteristics. Others spoke patterns provide maximum aeration for difficult materials which can be fluidized.

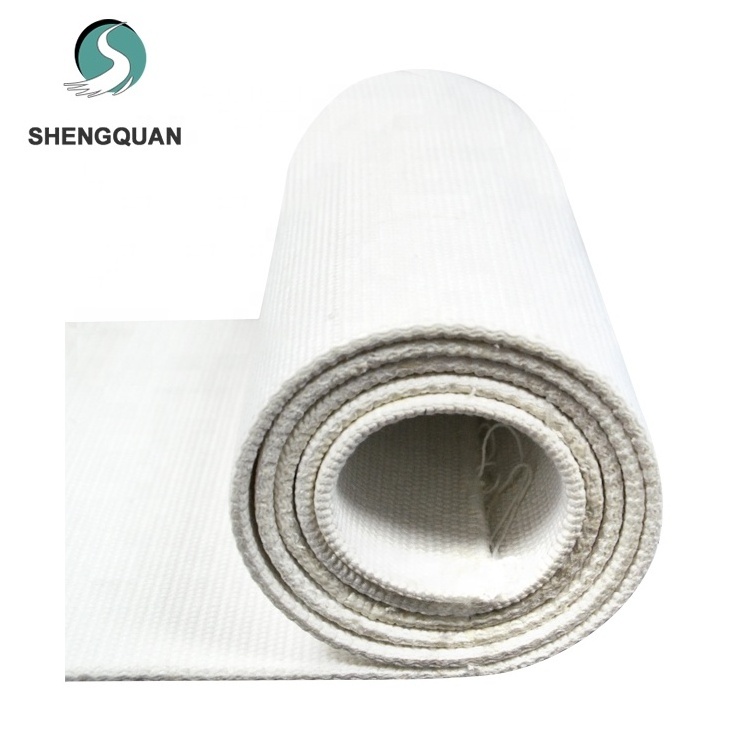

Specific ations :

| TYPE | MATERIAL | PLY | TENSILE STRENGTH | HEAT RESISTANCE ℃ | THICKNESS | WEIGHT/m2 | MAX WIDTH | AIR RESISTANCE IN | ||

| WARP >N/mm | WEFT >N/mm | 2m3/m2/minH2O mm | ||||||||

| AP4-4 | 100%Polyester | 4 | 360 | 270 | 150 | 4 | 3200g | 2000mm | Type A;80-120 | |

| Type B:120-150 | ||||||||||

| Type C:150-200 | ||||||||||

| AP4-5 | 100%Polyester | 4 | 360 | 270 | 150 | 5 | 3600g | 2000mm | Type A;80-120 | |

| Type B:120-150 | ||||||||||

| Type C:150-200 | ||||||||||

| AP4-6 | 100%Polyester | 4 | 360 | 270 | 150 | 6 | 4000g | 2000mm | Type A;80-120 | |

| Type B:120-150 | ||||||||||

| Type C:150-200 | ||||||||||

| AP4-7 | 100%Polyester | 4 | 360 | 270 | 150 | 7 | 4400g | 2000mm | Type A;80-120 | |

| Type B:120-150 | ||||||||||

| Type C:150-200 | ||||||||||

| AP4-8 | 100%Polyester | 4 | 360 | 270 | 150 | 8 | 4800g | 2000mm | Type A;80-120 | |

| Type B:120-150 | ||||||||||

| Type C:150-200 | ||||||||||

| AC4-5 | 100%Cotton | 4 | 150 | 100 | 150 | 5 | 3800g | 2000mm | Type A;80-120 | |

| Type B:120-150 | ||||||||||

|

Type C:150-200

|

||||||||||