Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DZX

-

Model Number:

-

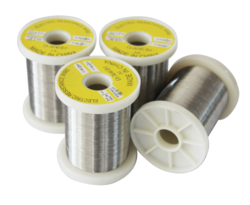

Tinned copper wire

-

Conductivity:

-

40%

-

Certification:

-

ROHS

-

Advantage:

-

Solderability

-

Size:

-

0.3-1.2mm

Quick Details

-

Application:

-

Overhead

-

Conductor Material:

-

Copper Clad Steel

-

Conductor Type:

-

Solid

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DZX

-

Model Number:

-

Tinned copper wire

-

Conductivity:

-

40%

-

Certification:

-

ROHS

-

Advantage:

-

Solderability

-

Size:

-

0.3-1.2mm

Products Description

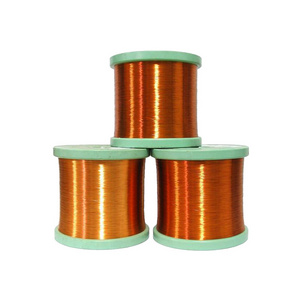

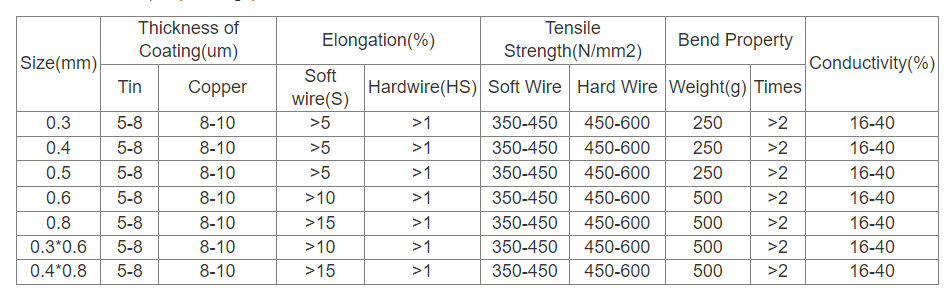

Tinned copper-clad steel flat/round wire

Advantages:

The high electrical conductivity and magnetic permeability of copper wire,

The high strength and bendability of steel wire,

The high thermal conductivity and corrosion resistance of tin,

Superior strength and weldability , excellent bending resistance

Vibration resistance is 3-6 times that of pure copper wire.

Applications:

It is suitable for leads and jumpers of a wide range of electronic components, such as resistors, capacitors, and core wires of

radio frequency cables. It is an ideal wire for communication, electronics, and power industries.

The relative conductivity of tinned copper-clad steel wire varies with the thickness of the cladding copper layer. The thicker the

cladding copper layer, the higher the relative conductivity. Generally, copper-clad steel with a relative conductivity of 16% to

40% is commonly used.

Tinned copper-clad copper wire has high rigidity and is easy to cut and form. It is suitable for the assembly process of the whole

machine and the automatic production process. The tensile strength is 2 times higher than that of ordinary tinned copper wire, and

the expansion coefficient of the wire is small. It is 13% lighter than tinned copper wire, and its length is 1.13 times that of

tinned copper wire when the wire diameter and weight are equal. At high frequencies, due to the agglomeration effect, it will

increase with the increase of frequency. At this time, the conductivity of the wire can be compared with that of copper wire with

the same diameter.

After aging in steam for 4 hours, it can still weld well after aging in a high temperature of 150ºC for 16 hours. The appearance

is smooth and clean, without exposed copper, detinned, black spots, rust, cracks, tin bumps, burrs, and the appearance is no

different from ordinary tinned copper wires.

ROHS Certified

Tinned copper-clad steel wire products are produced using raw materials that meet the "ROHS" standard (the core wire meets the

technical requirements of GB-3952-98 "Copper Wire Billets for Electrical Use"), equipment, tools, and auxiliary materials, and do

not contain Pb, Cd, and Hg. , Cr6+ and other harmful substances

The high electrical conductivity and magnetic permeability of copper wire,

The high strength and bendability of steel wire,

The high thermal conductivity and corrosion resistance of tin,

Superior strength and weldability , excellent bending resistance

Vibration resistance is 3-6 times that of pure copper wire.

Applications:

It is suitable for leads and jumpers of a wide range of electronic components, such as resistors, capacitors, and core wires of

radio frequency cables. It is an ideal wire for communication, electronics, and power industries.

The relative conductivity of tinned copper-clad steel wire varies with the thickness of the cladding copper layer. The thicker the

cladding copper layer, the higher the relative conductivity. Generally, copper-clad steel with a relative conductivity of 16% to

40% is commonly used.

Tinned copper-clad copper wire has high rigidity and is easy to cut and form. It is suitable for the assembly process of the whole

machine and the automatic production process. The tensile strength is 2 times higher than that of ordinary tinned copper wire, and

the expansion coefficient of the wire is small. It is 13% lighter than tinned copper wire, and its length is 1.13 times that of

tinned copper wire when the wire diameter and weight are equal. At high frequencies, due to the agglomeration effect, it will

increase with the increase of frequency. At this time, the conductivity of the wire can be compared with that of copper wire with

the same diameter.

After aging in steam for 4 hours, it can still weld well after aging in a high temperature of 150ºC for 16 hours. The appearance

is smooth and clean, without exposed copper, detinned, black spots, rust, cracks, tin bumps, burrs, and the appearance is no

different from ordinary tinned copper wires.

ROHS Certified

Tinned copper-clad steel wire products are produced using raw materials that meet the "ROHS" standard (the core wire meets the

technical requirements of GB-3952-98 "Copper Wire Billets for Electrical Use"), equipment, tools, and auxiliary materials, and do

not contain Pb, Cd, and Hg. , Cr6+ and other harmful substances

Specification

|

Stainless steel wire size tolerance

|

|

|

||

|

Wire diameter (mm)

|

Tolerance (mm)

|

Maximum deviation (mm)

|

||

|

0.-0.299

|

±0.005

|

0.005

|

||

|

0.300-0.310

|

±0.006

|

0.006

|

||

|

0.320-0.499

|

±0.006

|

0.006

|

||

|

0.500-0.599

|

±0.006

|

0.006

|

||

|

0.600-0.799

|

±0.008

|

0.008

|

||

|

0.800-0.999

|

±0.008

|

0.008

|

||

|

1.00-1.20

|

±0.009

|

0.009

|

||

|

1.20-1.40

|

±0.009

|

0.009

|

||

|

1.40-1.60

|

±0.010

|

0.010

|

||

|

1.60-1.80

|

±0.010

|

0.010

|

||

|

1.80-2.00

|

±0.010

|

0.010

|

||

|

2.00-2.50

|

±0.012

|

0.012

|

||

|

2.50-3.00

|

±0.015

|

0.015

|

||

|

3.00-4.00

|

±0.020

|

0.020

|

||

|

4.00-5.00

|

±0.020

|

0.020

|

||

Widely Use

About Us

JIANGSU DZX TECHNOLOGY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire,strip, ribbon, bar, tube, plate.

Customized service

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3,

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

How to contact professional sales?

Mobile/Whatsapp/Telegram: 86 133-2817 0953

Do you provide free samples?

Yes,we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

Hot Searches