- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

10 - 12000

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KaiboCNC

-

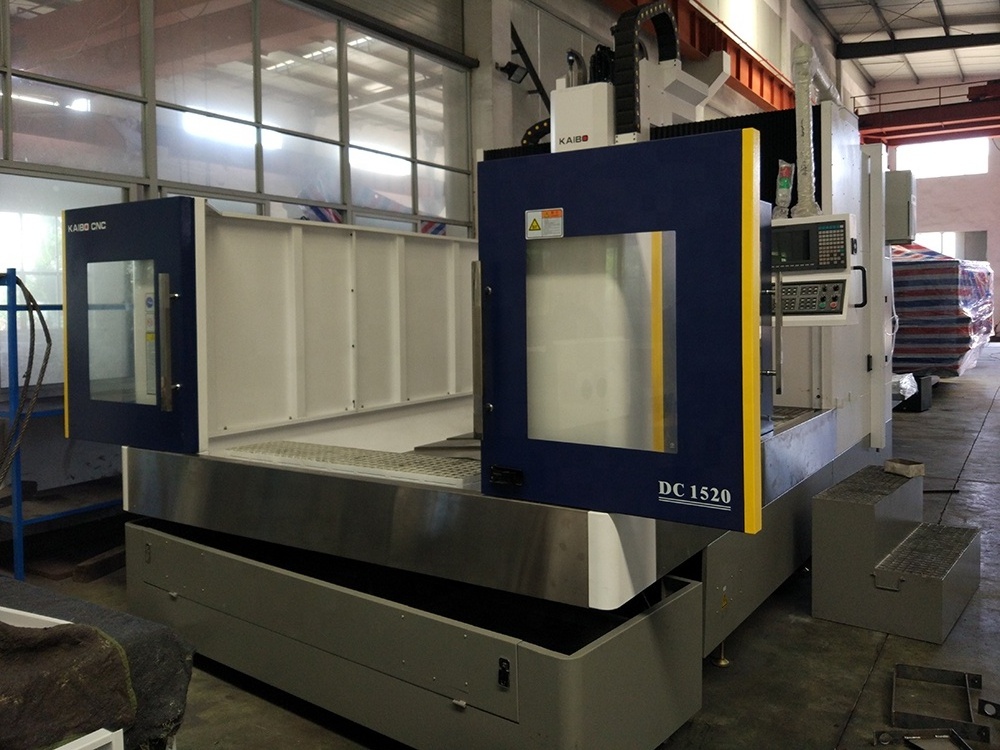

Model Number:

-

DC1520

-

Table Travel (mm):

-

1500*2000*720

-

Year:

-

2020

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5000*3040*3230

-

Weight (KG):

-

17000

-

Spindle Motor Power(kW):

-

15

-

Max. Table Load(kg):

-

3000 kg

-

Machine name:

-

CNC Milling Machine

-

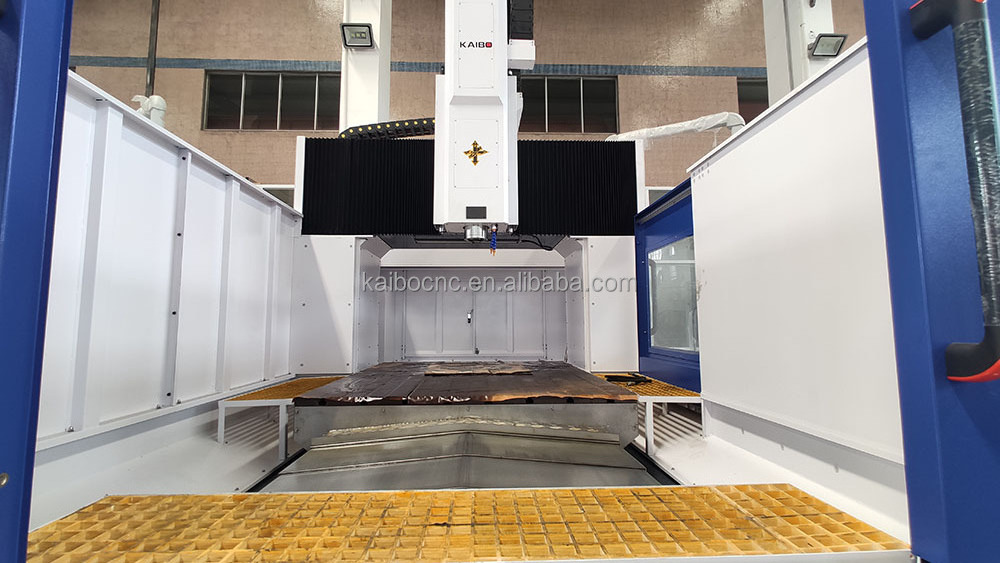

Machine Type:

-

Double Column

-

Worktable size:

-

1500*2000mm

-

X/Y/Z axis travel:

-

1500/2000/720mm

-

X/Y/Z axis motor power:

-

4400/4400/4400w

-

Gantry width:

-

1600mm

-

Beam to worktable:

-

900mm

-

Spindle:

-

BT40/15kw/8000rpm

-

Spindle nose to worktable:

-

135-855mm

-

Controller:

-

Syntec/Fanuc/Siemens/Mitsubishi

Quick Details

-

Table Travel (X) (mm):

-

1500

-

Table Travel (Y) (mm):

-

2000

-

Table Travel (Z) (mm):

-

700

-

Range of Spindle Speed(r.p.m):

-

10 - 12000

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KaiboCNC

-

Model Number:

-

DC1520

-

Table Travel (mm):

-

1500*2000*720

-

Year:

-

2020

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5000*3040*3230

-

Weight (KG):

-

17000

-

Spindle Motor Power(kW):

-

15

-

Max. Table Load(kg):

-

3000 kg

-

Machine name:

-

CNC Milling Machine

-

Machine Type:

-

Double Column

-

Worktable size:

-

1500*2000mm

-

X/Y/Z axis travel:

-

1500/2000/720mm

-

X/Y/Z axis motor power:

-

4400/4400/4400w

-

Gantry width:

-

1600mm

-

Beam to worktable:

-

900mm

-

Spindle:

-

BT40/15kw/8000rpm

-

Spindle nose to worktable:

-

135-855mm

-

Controller:

-

Syntec/Fanuc/Siemens/Mitsubishi

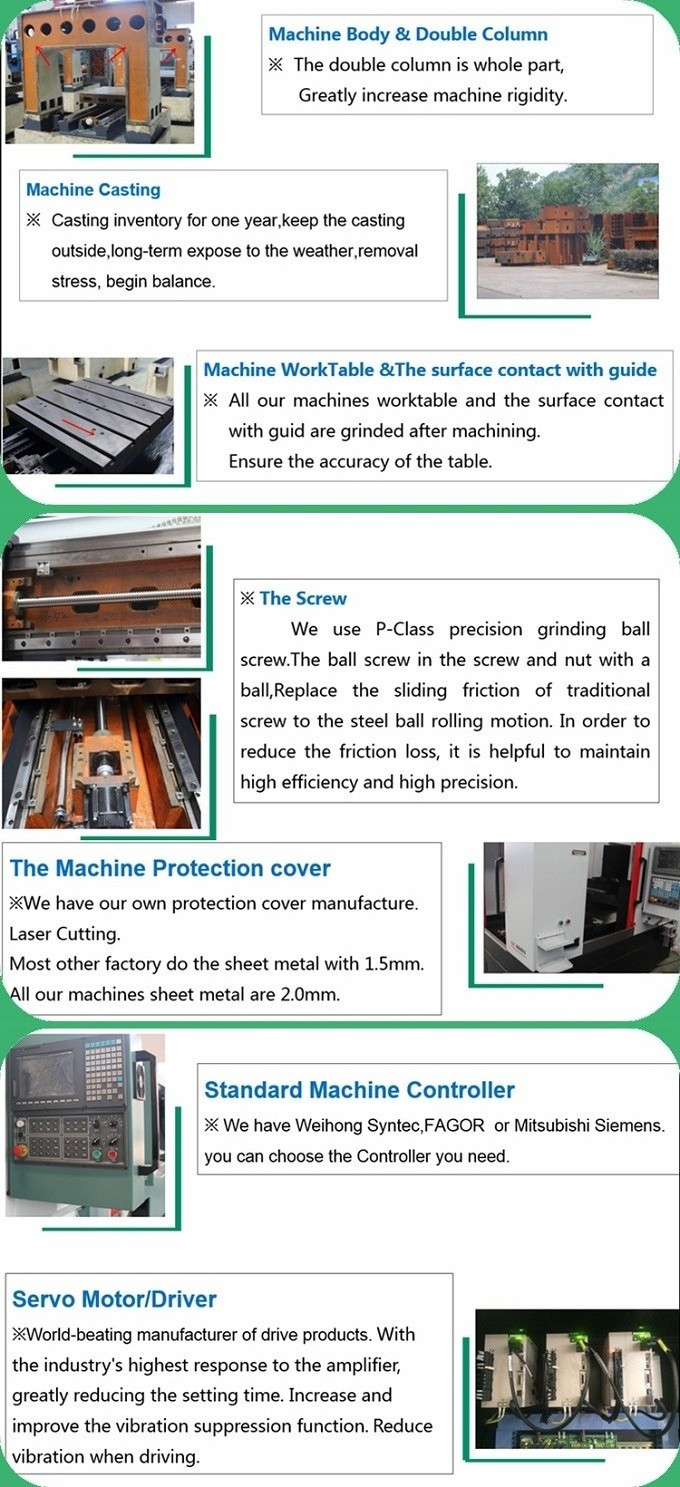

Standard features:

1.

Cooling system:

Oil circulating oil cooler for spindle,

cooling workpieces with water or oil in the tank or saponification liquid through or spray nozzle

2.

Gantry structure:

The double column is whole part, greatly increase machine rigidity.

3.

Quality

assurance:

Each device before leaving the factory, we will test the cue with laser interferometer

4. SYNTEC control system: from Taiwan with high performance and competitive price

5. Servo motor and drives: from Japan with high precision and long life

6. HIWIN linear guide: made from Taiwan,used for linear reciprocating stadium

8. Main axle: 1.5kw high precision variable frequency main axle turns machining into a kind of artistic model.

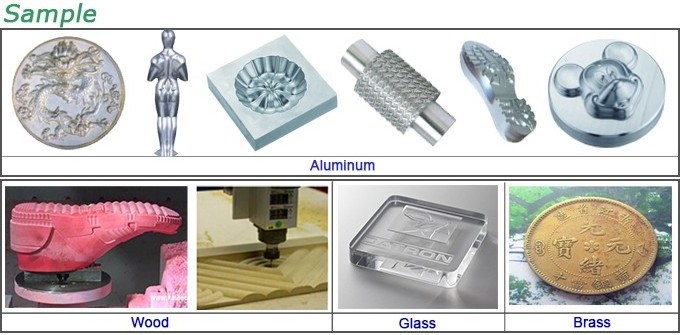

Application:

Processing material: Steel, iron, copper, aluminum, glass, wood and other materials

Option parts:

1.The working range can be customized as per your requests;

2.Control system: Weihong(Syntec or FAGOR) or as your request

3.

Can be 3 axis and 4 axis or 5 axis universal

.

4.Different linear guide, precision ball screw, servo motor, system components as your request

1.Description of CNC Machine

| Parameter/Model | DC-1520 | |

| Accuracy | Positioning accuracy | 0.01/300mm |

| Repeat positioning accuracy | 0.01mm | |

| Worktable | Worktable size | 1500*2000mm |

| T-slot size | 6T-12-180mm | |

| Max. load | 3000Kg | |

| Travel | X/Y/Z axis travel | 1500/2000/720mm |

| Gantry width | 1600mm | |

| Beam to worktable | 900mm | |

| Spindle nose to worktable | 135-855mm | |

| Feed | Max. feeding speed G00 | 12m/min |

| Max. working speed G01 | 8m/min | |

| X/Y/Z axis motor power | 4400w/4400w/4400w | |

| Spindle | Spindle motor power | 15KW |

| Spindle Max. speed | 8000rpm | |

| Tool holder | BT40 | |

| Tool Magazine(Opt.) | ATC type | Arm type |

| ATC capacity | 24pcs | |

| Common | Power supply and total capacity | 3P/380V/50Hz/30KVA |

| Machine weight | 17000Kg | |

| Dimension | 5000*3040*3230mm | |

2. Pictures of CNC Machine

Trade Item Of Products

| Transportation | always by sea |

| Payment terms | T/T,L/C At Sight or as your request |

| Package | 1 piece/carton,piece into a master carton |

| Delivery time | by sea,within 45 work days |

Our Best Services For You

1.Technician available for training and installation at customer's company

2.Internet service by sending emails and videos,communicating online or calling

3.We will reply you as soon as possible after we receive your email

4.We can offer both OEM and ODM service according to customers' request

5.If novelties exist in any non-human-made problems,please contact us at your first time and we will offer you a satisfied

solution according to your suitation