- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

0

-

Dimension(L*W*H):

-

1360*1360*5230mm

-

Weight:

-

800 KG

-

Feeding size:

-

0.3-0.037mm

-

Outer Diameter:

-

1200mm

-

Keywords:

-

Spiral Chute

-

Name:

-

Spiral Chute

-

Screw Picth:

-

900, 720,540mm

-

Materials:

-

Fiberglass

-

Separator:

-

Gravity Separator

-

Color:

-

as your request

-

Material:

-

Fiberglass

-

Usage:

-

Mining Separation

Quick Details

-

Production Capacity:

-

4-6tph

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Hengchang Spiral Chute

-

Voltage:

-

0

-

Dimension(L*W*H):

-

1360*1360*5230mm

-

Weight:

-

800 KG

-

Feeding size:

-

0.3-0.037mm

-

Outer Diameter:

-

1200mm

-

Keywords:

-

Spiral Chute

-

Name:

-

Spiral Chute

-

Screw Picth:

-

900, 720,540mm

-

Materials:

-

Fiberglass

-

Separator:

-

Gravity Separator

-

Color:

-

as your request

-

Material:

-

Fiberglass

-

Usage:

-

Mining Separation

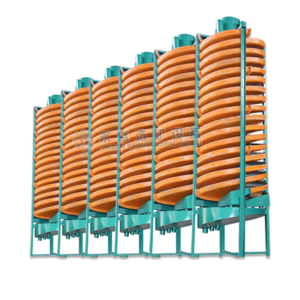

Beneficiation Equipment Chrome Ore Separator Gravity Spiral Chute Mineral Processing Gravity Separation Machine Spiral Chute

Hengchang machinery

Spiral Chute

can be used for many minerals separating, such as gold, copper, tungsten, tin, tantalum, coltan, chrome, zinc ore and some other minerals. When you find us, you find one best mining machinery manufacturer.

Spiral Chute

Introduction:

Spiral Chute is also called fiberglass spiral separator or spiral chute separator, is the best equipment in mining and ore dressing industries, which is often applied to sort materials with size 0.3 - 0.02 mm, such as ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphate, tungsten ore, tin, tantalum, niobium ore and other non-ferrous metals, precious metals and non-metallic minerals.

It can easily adopt to different raw material size, density, ore grade and feed volume. Spiral chute is suitable for treatment of 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold ore.

Spiral Chute Working Principle:

Spiral Chute is working under the the force of water flow, gravity, inertial centrifuge and friction. Slurry is pumped to the top of the spiral , and it enters a feed distributor that evenly distributes the feed to each spiral concentrator. The design and shape of the spiral make it work, when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density and to a lesser extend shape. Low density particles are carried with the bulk of the water towards the outside of the spiral , while particles with the greatest density migrate towards the inside of the spiral.

Spiral Chute Applications:

Spiral Separator is a gravity equipment. With the water, action of gravity friction force, minerals would be separated by its gravity difference. Then we could get heavy, middling and light products.It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; the advantages are light, moisture proof, anti-rust, wear proof,anti corrosion and no noise, properly suitable for the different feeding particle sizes and grades. It is the domestic advanced level, the new high effective equipment.

Spiral Chute is also called fiberglass spiral separator or spiral chute separator, is the best equipment in mining and ore dressing industries, which is often applied to sort materials with size 0.3 - 0.02 mm, such as ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphate, tungsten ore, tin, tantalum, niobium ore and other non-ferrous metals, precious metals and non-metallic minerals.

It can easily adopt to different raw material size, density, ore grade and feed volume. Spiral chute is suitable for treatment of 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold ore.

Spiral Chute Working Principle:

Spiral Chute is working under the the force of water flow, gravity, inertial centrifuge and friction. Slurry is pumped to the top of the spiral , and it enters a feed distributor that evenly distributes the feed to each spiral concentrator. The design and shape of the spiral make it work, when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density and to a lesser extend shape. Low density particles are carried with the bulk of the water towards the outside of the spiral , while particles with the greatest density migrate towards the inside of the spiral.

Spiral Chute Applications:

Spiral Separator is a gravity equipment. With the water, action of gravity friction force, minerals would be separated by its gravity difference. Then we could get heavy, middling and light products.It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; the advantages are light, moisture proof, anti-rust, wear proof,anti corrosion and no noise, properly suitable for the different feeding particle sizes and grades. It is the domestic advanced level, the new high effective equipment.

Inner surface without riffiles/ grooves

For Separate the Fine particles and Slurry ore.

Inner surface with riffles/grooves

is to separator the ore with Coarse particles

|

Model

|

BLL-1500

|

BLL-1200

|

BLL-900

|

BLL-600

|

BLL-400

|

|

Outside Diameter

(mm)

|

1500

|

1200

|

900

|

600

|

400

|

|

Screw Pitch

(mm)

|

900, 675

|

900, 720, 540

|

675, 540, 405

|

450, 360, 270

|

240, 180

|

|

Pitch Diameter Ratio

|

0.48, 0.36

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.6, 0.45

|

|

Lateral slope

(degree)

|

9°

|

9°

|

9°

|

9°

|

9°

|

|

Max. Screw Numbers

|

4

|

4

|

4

|

2

|

2

|

|

Feed Size (mm)

|

0.8 ~0.037

|

0.3~0.03

|

0.3 ~0.03

|

0.2~0.02

|

0.2 ~0.02

|

|

Feed Density (%)

|

30 ~55

|

25 ~55

|

25 ~55

|

25 ~55

|

25 ~55

|

|

Capacity (t/h)

|

6~8

|

4~6

|

2~3

|

0.8~1.2

|

0.15~0.2

|

|

Length (mm)

|

1600

|

1360

|

1060

|

700

|

460

|

|

Width (mm)

|

1600

|

1360

|

1060

|

700

|

460

|

|

Height (mm)

|

5300

|

5230

|

4000

|

2600

|

1500

|

|

Weight (kg)

|

850/800

|

700/650/600

|

450/400/350

|

150/120/100

|

50

|

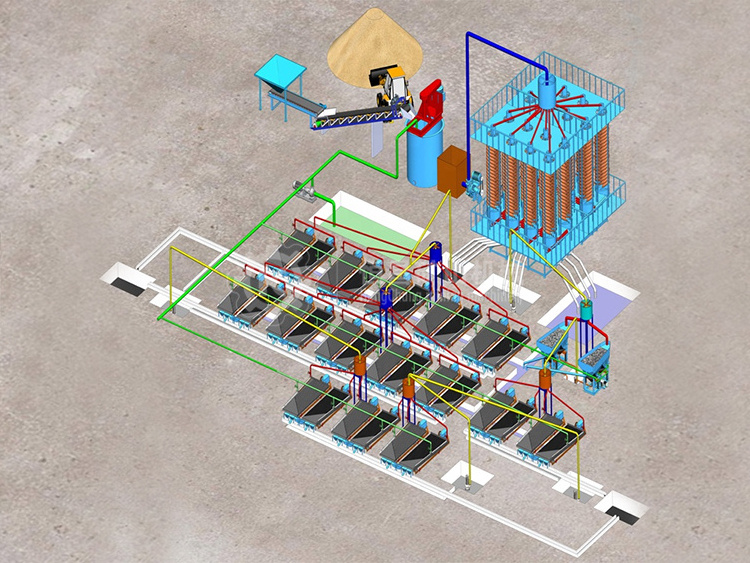

Spiral Chute

In Zimbabwe

Used in alluvial gold processing plant

Spiral Chute

In South Africa

Used in chrome ore separation

Spiral Separator

In Indonesia

Used in black sand separation plant

Spiral Separator

In India

Used in tin ore concentration plant

Spiral Chute in

Myanmar

Used in Tungsten ore separator line

Spiral Chute

In

Pakistan

Used in iron ore gold separator processing

Spiral Chute

In

Puerto Rico

Used in coal separator plant

Spiral Separator

In Australia

used in beach sand gold separator

Hot Searches