- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LLY PACK

-

Dimension(L*W*H):

-

22940*2300*2600mm

-

Weight:

-

8500 KG

-

Product name:

-

Corrugated Flute Laminator Machine

-

Max paper size:

-

1700x1650mm

-

Min paper size:

-

360x380mm

-

Top sheet thickness:

-

128g/㎡-450 g/㎡

-

Bottom sheet thickness:

-

0.5mm-10mm Sheet to sheet lamination:250+gsm

-

Max. working speed:

-

148m/min

-

Max. machine speed:

-

Lamination part 14800 pcs/hr Stacker 12000 pcs/hr

-

Lamination Precision:

-

±0.5mm to ±1.5 mm

-

Machine power:

-

23.57kw+9kw

-

Suitable for:

-

Corrugated board, Duplex board, Grey board

Quick Details

-

Packaging Type:

-

Cartons, Corrugated Cardboard

-

Packaging Material:

-

Paper

-

Driven Type:

-

Electric

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LLY PACK

-

Dimension(L*W*H):

-

22940*2300*2600mm

-

Weight:

-

8500 KG

-

Product name:

-

Corrugated Flute Laminator Machine

-

Max paper size:

-

1700x1650mm

-

Min paper size:

-

360x380mm

-

Top sheet thickness:

-

128g/㎡-450 g/㎡

-

Bottom sheet thickness:

-

0.5mm-10mm Sheet to sheet lamination:250+gsm

-

Max. working speed:

-

148m/min

-

Max. machine speed:

-

Lamination part 14800 pcs/hr Stacker 12000 pcs/hr

-

Lamination Precision:

-

±0.5mm to ±1.5 mm

-

Machine power:

-

23.57kw+9kw

-

Suitable for:

-

Corrugated board, Duplex board, Grey board

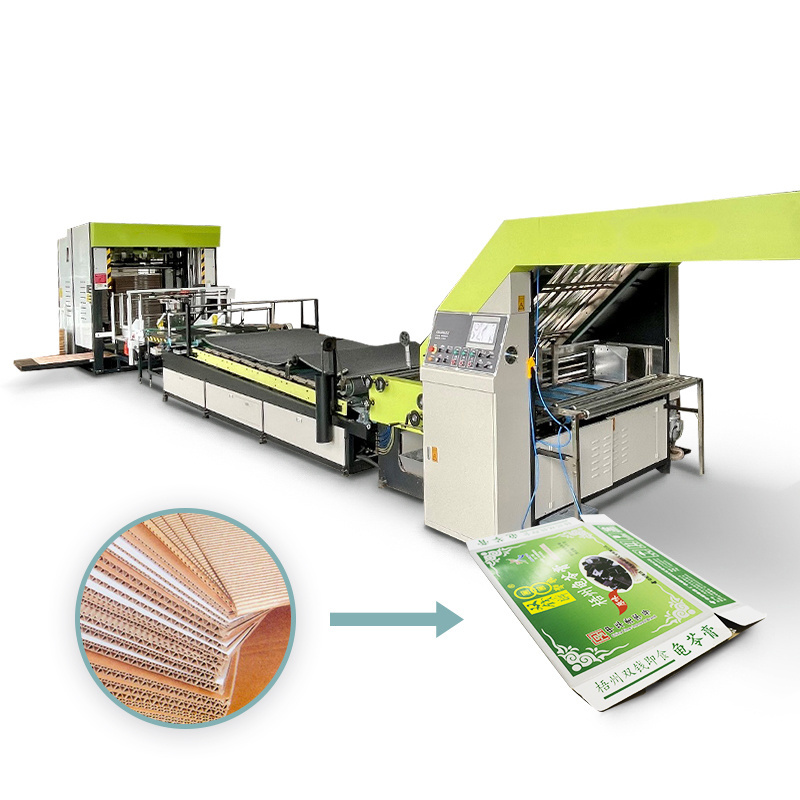

Products Description

Corrugated Flute Laminator Machine

From high speed feeding, gluing, laminating, pressing to flip flop stacking and automatic delivery, model HBF completes the whole lamination job by just one time. It fundamentally solve the original tedious and complicated process of flute lamination job, substantially decreases the production’s transition step and labor intensity thus to save companies’ operation cost.

* HBZ-170 feeder uses servo shaft-less control conveying way, which will not be restricted by paper size and can send paper precisely.

Machine consists of: sub-stacker, lifting part, main stacker and automatic delivering part.

|

MODEL

|

HBF-170

|

|

Max paper size

|

1700x1650mm

|

|

Min paper size

|

360x380mm

|

|

Top sheet thickness

|

128g/㎡-450 g/㎡

|

|

Bottom sheet thickness

|

0.5mm-10mm

Sheet to sheet lamination:250+gsm |

|

Max. working speed

|

148m/min

|

|

Max. machine speed

|

Lamination part 14800 pcs/hr

Stacker 12000 pcs/hr |

|

Lamination error

|

±0.5mm to ±1.5 mm

|

|

Machine power

|

23.57kw+9kw

|

|

Actual power

|

15kw

|

|

Machine size(L×W×H)

|

22940×2300×2600mm

|

|

Machine weight

|

8500kg+5800kg

|

HIGH APPLICABILITY

* It is used for laminating cardboard to corrugated board

* It is mainly suitable for the below paper

Corrugated board

B/E/F-flute

Duplex board

Grey board

SUB-STACKER

* Use wide rubber belts to connect it with laminator for running synchronously.

* Set a certain paper stacking quantity, by reach that number, paper will be sent to the flipping unit automatically

* It pat the paper from the front and two sides to make the paper piled neatly.

* Accurate positioning based on variable frequency technology.

* Paper pushing driven by motor.

* Non-resistant paper pushing.

* Set a certain paper stacking quantity, by reach that number, paper will be sent to the flipping unit automatically

* It pat the paper from the front and two sides to make the paper piled neatly.

* Accurate positioning based on variable frequency technology.

* Paper pushing driven by motor.

* Non-resistant paper pushing.

LIFTING PART

* When paper first be sent to the flipping unit, the lifting motor will raise the paper to the setting height.

* During the second delivering process, paper will be sent to the main stacker.

* Accurate positioning based on variable frequency technology.

* Motor-driven paper flipping. Paper can be stacked with one pile front side up and one pile back side up alternately, or all with their front sides up and all with their back sides up.

* Use variable frequency motor to push paper.

* Tray inlet.

* Touch screen control.

* During the second delivering process, paper will be sent to the main stacker.

* Accurate positioning based on variable frequency technology.

* Motor-driven paper flipping. Paper can be stacked with one pile front side up and one pile back side up alternately, or all with their front sides up and all with their back sides up.

* Use variable frequency motor to push paper.

* Tray inlet.

* Touch screen control.

MAIN STACKER

* Rear positioning, and paper patting from 3 sides: front side, left side and right side.

* Pre-stacking device for non-stop delivering.

* Paper stacking height is adjustable between 1400mm to 1750mm. The height can be increased according to customer requirements.

* Pre-stacking device for non-stop delivering.

* Paper stacking height is adjustable between 1400mm to 1750mm. The height can be increased according to customer requirements.

DELIVERING PART

* When paper stacker is full, motor will drive paper pile out automatically.

* At the same time, the empty tray will be lifted up to original position.

* Paper pile will be pulled away by a pallet jack from the slope.

* At the same time, the empty tray will be lifted up to original position.

* Paper pile will be pulled away by a pallet jack from the slope.

Hot Searches